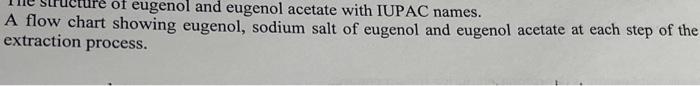

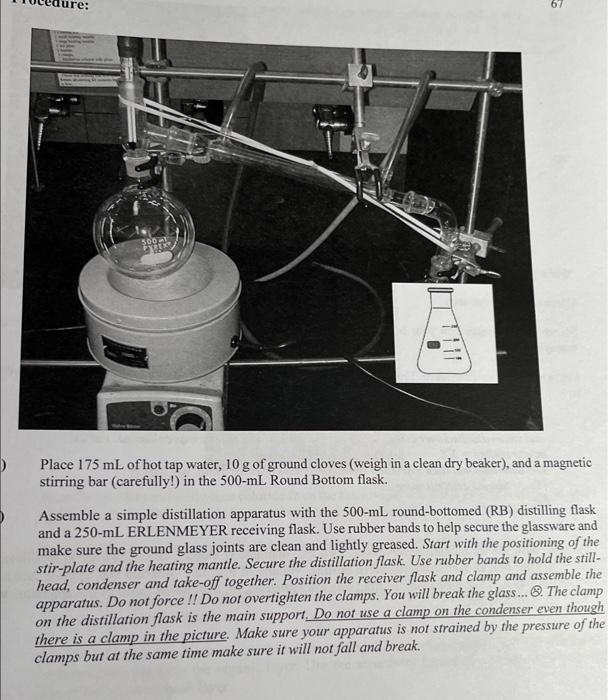

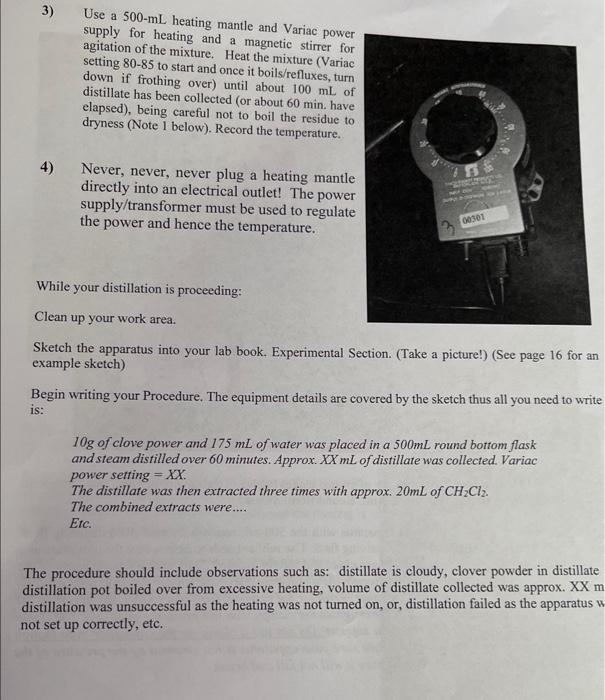

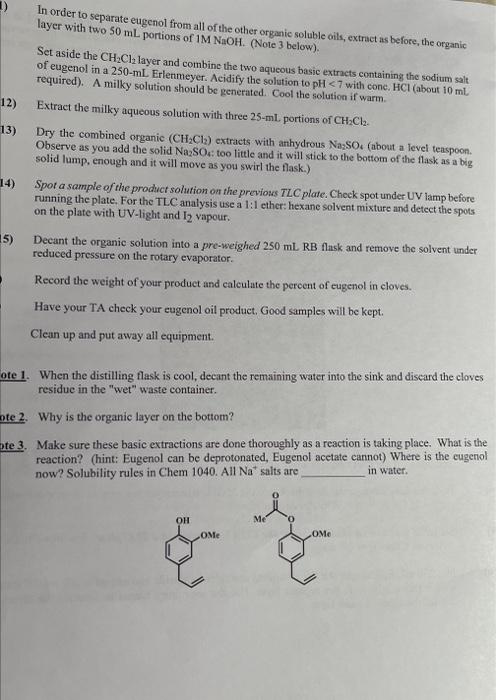

A flow chart showing eugenol, sodium salt of eugenol and eugenol acetate at each step of the extraction process. Place 175mL of hot tap water, 10g of ground cloves (weigh in a clean dry beaker), and a magnetic stirring bar (carefully!) in the 500 -mL Round Bottom flask. Assemble a simple distillation apparatus with the 500mL round-bottomed (RB) distilling flask and a 250 -mL ERLENMEYER receiving flask. Use rubber bands to help secure the glassware and make sure the ground glass joints are clean and lightly greased. Start with the positioning of the stir-plate and the heating mantle. Secure the distillation flask. Use rubber bands to hold the stillhead, condenser and take-off together. Position the receiver flask and clamp and assemble the apparatus. Do not force !! Do not overtighten the clamps. You will break the glass... 8 . The clamp on the distillation flask is the main support. Do not use a clamp on the condenser even though there is a clamp in the picture. Make sure your apparatus is not strained by the pressure of the clamps but at the same time make sure it will not fall and break. 3) Use a 500mL heating mantle and Variac power supply for heating and a magnetic stirrer for agitation of the mixture. Heat the mixture (Variac setting 80-85 to start and once it boils/refluxes, turn down if frothing over) until about 100mL of distillate has been collected (or about 60min. have elapsed), being careful not to boil the residue to dryness (Note 1 below). Record the temperature. 4) Never, never, never plug a heating mantle directly into an electrical outlet! The power supply/transformer must be used to regulate the power and hence the temperature. While your distillation is proceeding: Clean up your work area. Sketch the apparatus into your lab book. Experimental Section. (Take a picture!) (See page 16 for an example sketch) Begin writing your Procedure. The equipment details are covered by the sketch thus all you need to write is: 10g of clove power and 175mL of water was placed in a 500mL round bottom flask and steam distilled over 60 minutes. Approx. XX m L of distillate was collected. Variac power setting =XX. The distillate was then extracted three times with approx. 20mL of CH2Cl2. The combined extracts were.... Etc. The procedure should include observations such as: distillate is cloudy, clover powder in distillate distillation pot boiled over from excessive heating, volume of distillate collected was approx. XX m distillation was unsuccessful as the heating was not turned on, or, distillation failed as the apparatus not set up correctly, etc. 5) Take the 250-mL Erlenmeyer containing the oil/water distillate and add a stir bar, Cool in an 69 ice/water bath if warm to the touch. Add 25mL of methylene chloride (CH2Cl2) to the Erlenmeyer. Stir the two solvent layers for a minute or two. Do not stir too fast as an emulsion will form and the layers will take too long to separate once you stop mixing. Stop stirring. 6) Carefully disassemble the distillation apparatus, clean and put it away. Pour the distillate and methylene chloride from the Erlenmeyer into the separatory funnel, let settle and drain off the lower organic layer into a 125 -mL Erlenmeyer flask (Note 2 below). Pour the distillate/aqueous layer back into the 250mL erlenmeyer and extract twice more with 25 mLCH2Cl2 as above. Why three extractions? Set aside the aqueous phase and spot the CH2Cl2 solution on a TLC plate. Spot heavily. DO not run yet. Check spot UV lamp. In a 250mL Erlenmeyer stir the combined methylene chloride extracts with 100mL of water to wash/remove salts from the organic layer. Use the separatory funnel to separate the layers and discard the aqueous wash layer. 13) Dry the combined organic (CH2Cl2) extracts with anhydrous Na2SO4 (about a level teaspoon. Observe as you add the solid Na2SO4 : too little and it will stick to the bottom of the flask as a big solid lump, enough and it will move as you swirl the flask.) 14) Spot a sample of the product solution on the previoss TLC plate. Check spot under UV lamp before running the plate. For the TLC analysis use a 1:1 ether: hexane solvent mixture and detect the spots on the plate with UV-light and I vapour. 5) Deeant the organic solution into a pre-weighed 250mL RB flask and remove the solvent under reduced pressure on the rotary evaporator. Record the weight of your product and calculate the percent of eugenol in cloves. Have your TA check your eugenol oil product. Good samples will be kept. Clean up and put away all equipment. ote 1. When the distilling flask is cool, decant the remaining water into the sink and discard the cloves residue in the "wet" waste container. W. Why is the organic layer on the bottom? 3. Make sure these basic extractions are done thoroughly as a reaction is taking place. What is the reaction? (hint: Eugenol can be deprotonated, Eugenol acetate cannot) Where is the cugenol now? Solubility rules in Chem 1040 . All Na+salts are in water. A flow chart showing eugenol, sodium salt of eugenol and eugenol acetate at each step of the extraction process. Place 175mL of hot tap water, 10g of ground cloves (weigh in a clean dry beaker), and a magnetic stirring bar (carefully!) in the 500 -mL Round Bottom flask. Assemble a simple distillation apparatus with the 500mL round-bottomed (RB) distilling flask and a 250 -mL ERLENMEYER receiving flask. Use rubber bands to help secure the glassware and make sure the ground glass joints are clean and lightly greased. Start with the positioning of the stir-plate and the heating mantle. Secure the distillation flask. Use rubber bands to hold the stillhead, condenser and take-off together. Position the receiver flask and clamp and assemble the apparatus. Do not force !! Do not overtighten the clamps. You will break the glass... 8 . The clamp on the distillation flask is the main support. Do not use a clamp on the condenser even though there is a clamp in the picture. Make sure your apparatus is not strained by the pressure of the clamps but at the same time make sure it will not fall and break. 3) Use a 500mL heating mantle and Variac power supply for heating and a magnetic stirrer for agitation of the mixture. Heat the mixture (Variac setting 80-85 to start and once it boils/refluxes, turn down if frothing over) until about 100mL of distillate has been collected (or about 60min. have elapsed), being careful not to boil the residue to dryness (Note 1 below). Record the temperature. 4) Never, never, never plug a heating mantle directly into an electrical outlet! The power supply/transformer must be used to regulate the power and hence the temperature. While your distillation is proceeding: Clean up your work area. Sketch the apparatus into your lab book. Experimental Section. (Take a picture!) (See page 16 for an example sketch) Begin writing your Procedure. The equipment details are covered by the sketch thus all you need to write is: 10g of clove power and 175mL of water was placed in a 500mL round bottom flask and steam distilled over 60 minutes. Approx. XX m L of distillate was collected. Variac power setting =XX. The distillate was then extracted three times with approx. 20mL of CH2Cl2. The combined extracts were.... Etc. The procedure should include observations such as: distillate is cloudy, clover powder in distillate distillation pot boiled over from excessive heating, volume of distillate collected was approx. XX m distillation was unsuccessful as the heating was not turned on, or, distillation failed as the apparatus not set up correctly, etc. 5) Take the 250-mL Erlenmeyer containing the oil/water distillate and add a stir bar, Cool in an 69 ice/water bath if warm to the touch. Add 25mL of methylene chloride (CH2Cl2) to the Erlenmeyer. Stir the two solvent layers for a minute or two. Do not stir too fast as an emulsion will form and the layers will take too long to separate once you stop mixing. Stop stirring. 6) Carefully disassemble the distillation apparatus, clean and put it away. Pour the distillate and methylene chloride from the Erlenmeyer into the separatory funnel, let settle and drain off the lower organic layer into a 125 -mL Erlenmeyer flask (Note 2 below). Pour the distillate/aqueous layer back into the 250mL erlenmeyer and extract twice more with 25 mLCH2Cl2 as above. Why three extractions? Set aside the aqueous phase and spot the CH2Cl2 solution on a TLC plate. Spot heavily. DO not run yet. Check spot UV lamp. In a 250mL Erlenmeyer stir the combined methylene chloride extracts with 100mL of water to wash/remove salts from the organic layer. Use the separatory funnel to separate the layers and discard the aqueous wash layer. 13) Dry the combined organic (CH2Cl2) extracts with anhydrous Na2SO4 (about a level teaspoon. Observe as you add the solid Na2SO4 : too little and it will stick to the bottom of the flask as a big solid lump, enough and it will move as you swirl the flask.) 14) Spot a sample of the product solution on the previoss TLC plate. Check spot under UV lamp before running the plate. For the TLC analysis use a 1:1 ether: hexane solvent mixture and detect the spots on the plate with UV-light and I vapour. 5) Deeant the organic solution into a pre-weighed 250mL RB flask and remove the solvent under reduced pressure on the rotary evaporator. Record the weight of your product and calculate the percent of eugenol in cloves. Have your TA check your eugenol oil product. Good samples will be kept. Clean up and put away all equipment. ote 1. When the distilling flask is cool, decant the remaining water into the sink and discard the cloves residue in the "wet" waste container. W. Why is the organic layer on the bottom? 3. Make sure these basic extractions are done thoroughly as a reaction is taking place. What is the reaction? (hint: Eugenol can be deprotonated, Eugenol acetate cannot) Where is the cugenol now? Solubility rules in Chem 1040 . All Na+salts are in water