Answered step by step

Verified Expert Solution

Question

1 Approved Answer

A machine shop is tasked with processing five different products in four workstations, and operates 40 hours per week. Part-mix ratios, batch quantities, part routings,

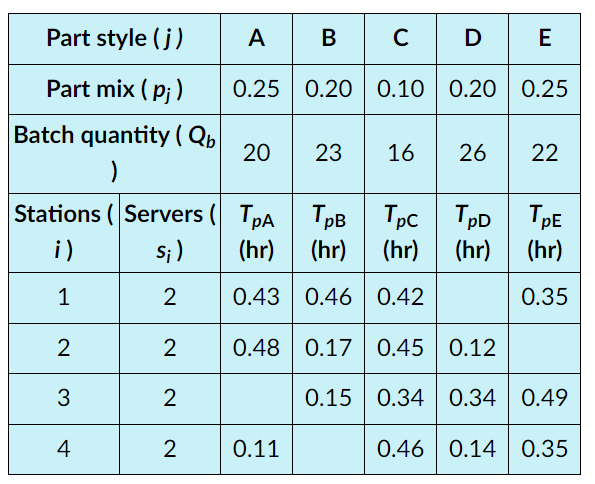

A machine shop is tasked with processing five different products in four workstations, and operates 40 hours per week. Part-mix ratios, batch quantities, part routings, machines, servers, and production times are given in the table below for the five part styles produced in the shop. Part production times include an allowance for setup time that is based on the batch quantity for each part style. Production records indicate that the average nonproductive time associated with each operation is 13hrs. Operation sequence for each part style is in the order of station number. Part styles are identified by letter and stations are identified by number. Determine the average lead time for all four part styles (hours, 2 decimal points). \begin{tabular}{|c|c|c|c|c|c|c|} \hline \multicolumn{2}{|c|}{ Part style (j)} & A & B & C & D & E \\ \hline \multicolumn{2}{|c|}{ Part mix (pj)} & 0.25 & 0.20 & 0.10 & 0.20 & 0.25 \\ \hline \multicolumn{2}{|c|}{ Batch quantity (Qb} & 20 & 23 & 16 & 26 & 22 \\ \hline Stations(i) & Servers(si) & TpA(hr) & TpB(hr) & TpC(hr) & TpD(hr) & TpE(hr) \\ \hline 1 & 2 & 0.43 & 0.46 & 0.42 & & 0.35 \\ \hline 2 & 2 & 0.48 & 0.17 & 0.45 & 0.12 & \\ \hline 3 & 2 & & 0.15 & 0.34 & 0.34 & 0.49 \\ \hline 4 & 2 & 0.11 & & 0.46 & 0.14 & 0.35 \\ \hline \end{tabular}

A machine shop is tasked with processing five different products in four workstations, and operates 40 hours per week. Part-mix ratios, batch quantities, part routings, machines, servers, and production times are given in the table below for the five part styles produced in the shop. Part production times include an allowance for setup time that is based on the batch quantity for each part style. Production records indicate that the average nonproductive time associated with each operation is 13hrs. Operation sequence for each part style is in the order of station number. Part styles are identified by letter and stations are identified by number. Determine the average lead time for all four part styles (hours, 2 decimal points). \begin{tabular}{|c|c|c|c|c|c|c|} \hline \multicolumn{2}{|c|}{ Part style (j)} & A & B & C & D & E \\ \hline \multicolumn{2}{|c|}{ Part mix (pj)} & 0.25 & 0.20 & 0.10 & 0.20 & 0.25 \\ \hline \multicolumn{2}{|c|}{ Batch quantity (Qb} & 20 & 23 & 16 & 26 & 22 \\ \hline Stations(i) & Servers(si) & TpA(hr) & TpB(hr) & TpC(hr) & TpD(hr) & TpE(hr) \\ \hline 1 & 2 & 0.43 & 0.46 & 0.42 & & 0.35 \\ \hline 2 & 2 & 0.48 & 0.17 & 0.45 & 0.12 & \\ \hline 3 & 2 & & 0.15 & 0.34 & 0.34 & 0.49 \\ \hline 4 & 2 & 0.11 & & 0.46 & 0.14 & 0.35 \\ \hline \end{tabular} Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started