Question

A major manufacturer of mobile phones uses inventory, overtime, and subcontracting to accommodate periodic demand fluctuations. The company creates a production plan annually but updates

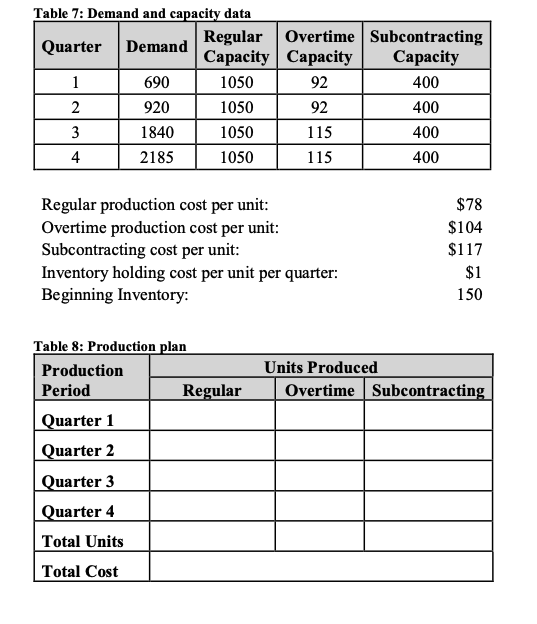

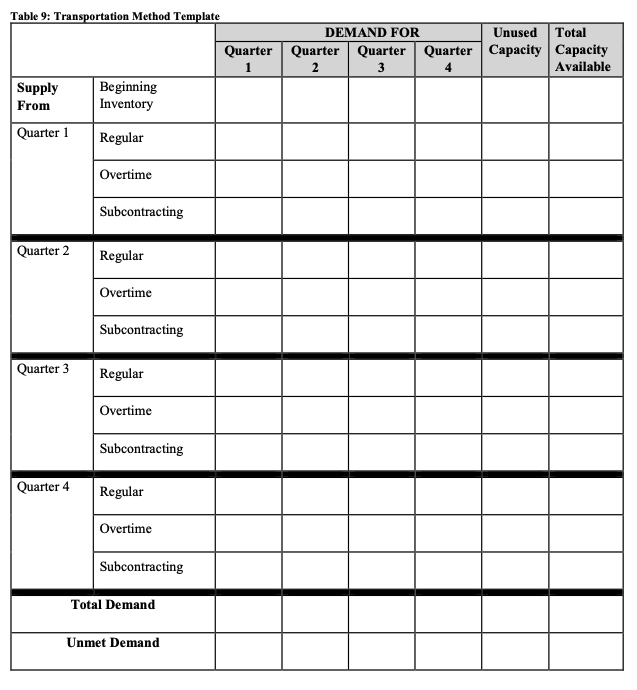

A major manufacturer of mobile phones uses inventory, overtime, and subcontracting to accommodate periodic demand fluctuations. The company creates a production plan annually but updates it quarterly. Table 7 below provides the expected demand and available capacities for the companys next four quarters (values are in units). Use the transportation method to design a minimum cost production plan that will satisfy demand for the upcoming year. They have 150 units in inventory at the beginning of the planning period and backordering is not permitted.

-

FillinTable8belowspecifyinghowmanyunitswillbeproducedeachperiodusingthe3typesofcapacity (i.e., regular, overtime, and subcontracting). (15)

-

Include the total cost for the production plan for the year in the last row of Table 8. (5)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started