Answered step by step

Verified Expert Solution

Question

1 Approved Answer

-. A major sensor manufacturer is considering two alternatives for new production machines with capacity to produce 20,000 units per day. One alternative is

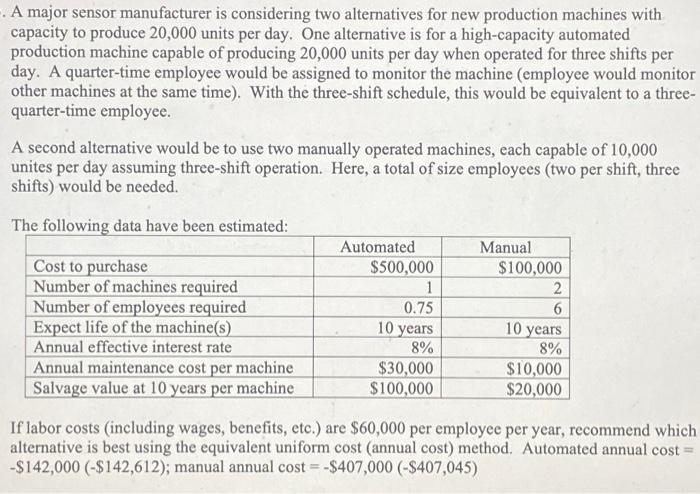

-. A major sensor manufacturer is considering two alternatives for new production machines with capacity to produce 20,000 units per day. One alternative is for a high-capacity automated production machine capable of producing 20,000 units per day when operated for three shifts per day. A quarter-time employee would be assigned to monitor the machine (employee would monitor other machines at the same time). With the three-shift schedule, this would be equivalent to a three- quarter-time employee. A second alternative would be to use two manually operated machines, each capable of 10,000 unites per day assuming three-shift operation. Here, a total of size employees (two per shift, three shifts) would be needed. The following data have been estimated: Cost to purchase Number of machines required Number of employees required Expect life of the machine(s) Annual effective interest rate Annual maintenance cost per machine Salvage value at 10 years per machine Automated $500,000 1 0.75 0 years 8% 10 y $30,000 $100,000 Manual $100,000 2 6 10 years 8% $10,000 $20,000 If labor costs (including wages, benefits, etc.) are $60,000 per employee per year, recommend which alternative is best using the equivalent uniform cost (annual cost) method. Automated annual cost = -$142,000 (-$142,612); manual annual cost=-$407,000 (-$407,045)

Step by Step Solution

★★★★★

3.28 Rating (154 Votes )

There are 3 Steps involved in it

Step: 1

To determine which alternative is best we need to calculate the equivalent uniform cost annual cost ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started