Question: A manual assembly line is to be designed to make a small consumer product. The work elements, their times, and precedence constraints are given

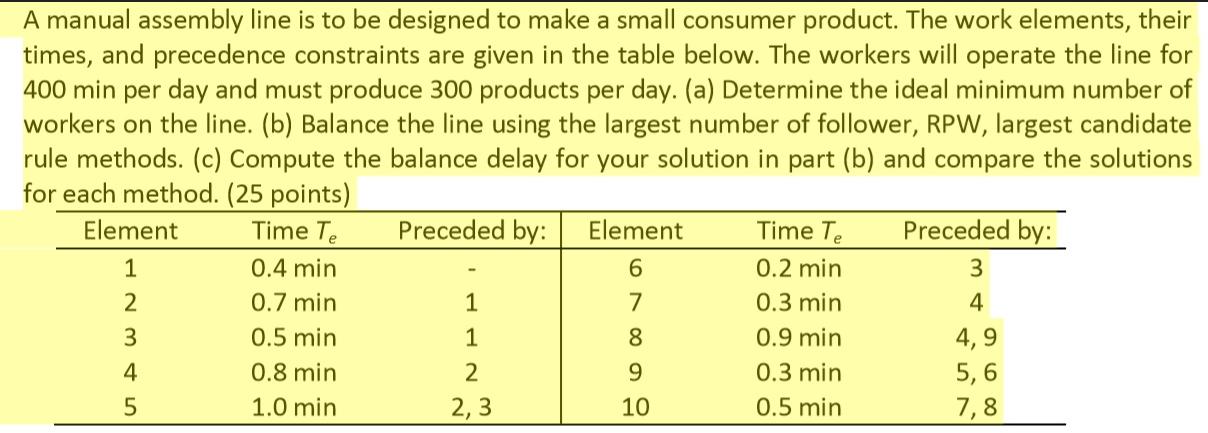

A manual assembly line is to be designed to make a small consumer product. The work elements, their times, and precedence constraints are given in the table below. The workers will operate the line for 400 min per day and must produce 300 products per day. (a) Determine the ideal minimum number of workers on the line. (b) Balance the line using the largest number of follower, RPW, largest candidate rule methods. (c) Compute the balance delay for your solution in part (b) and compare the solutions for each method. (25 points) Element Time Te Preceded by: 0.4 min 0.7 min 0.5 min 0.8 min 1.0 min L2345 1 1 1 2 2,3 Element 6 7 8 9 10 Time Te 0.2 min 0.3 min 0.9 min 0.3 min 0.5 min Preceded by: 3 4 4,9 5, 6 7,8

Step by Step Solution

3.32 Rating (152 Votes )

There are 3 Steps involved in it

To address this assembly line balancing problem well follow these steps a Determine the ideal minimum number of workers on the line b Balance the line using the Largest Number of Followers Rule LNFR R... View full answer

Get step-by-step solutions from verified subject matter experts