Answered step by step

Verified Expert Solution

Question

1 Approved Answer

A manual assembly line is to be designed to make a small consumer product. The work elements, their times, and precedence constraints are given in

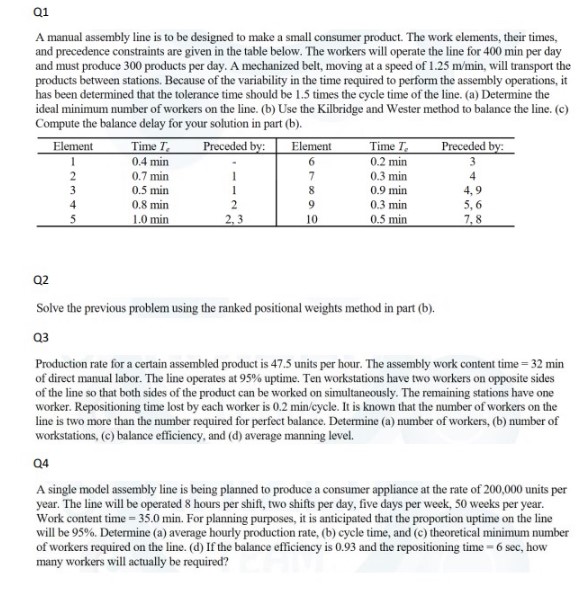

A manual assembly line is to be designed to make a small consumer product. The work elements, their times, and precedence constraints are given in the table below. The workers will operate the line for 400min per day and must produce 300 products per day. A mechanized belt, moving at a speed of 1.25m/min, will transport the products between stations. Because of the variability in the time required to perform the assembly operations, it has been determined that the tolerance time should be 1.5 times the cycle time of the line. (a) Determine the ideal minimum number of workers on the line. (b) Use the Kilbridge and Wester method to balance the line. (c) Compute the balance delay for your solution in part (b). Q2 Solve the previous problem using the ranked positional weights method in part (b). Q3 Production rate for a certain assembled product is 47.5 units per hour. The assembly work content time =32min of direct manual labor. The line operates at 95% uptime. Ten workstations have two workers on opposite sides of the line so that both sides of the product can be worked on simultaneously. The remaining stations have one worker. Repositioning time lost by each worker is 0.2min/ cycle. It is known that the number of workers on the line is two more than the number required for perfect balance. Determine (a) number of workers, (b) number of workstations, (c) balance efficiency, and (d) average manning level. Q4 A single model assembly line is being planned to produce a consumer appliance at the rate of 200,000 units per year. The line will be operated 8 hours per shift, two shifts per day, five days per week, 50 weeks per year. Work content time =35.0min. For planning purposes, it is anticipated that the proportion uptime on the line will be 95%. Determine (a) average hourly production rate, (b) cycle time, and (c) theoretical minimum number of workers required on the line. (d) If the balance efficiency is 0.93 and the repositioning time =6sec, how many workers will actually be required

A manual assembly line is to be designed to make a small consumer product. The work elements, their times, and precedence constraints are given in the table below. The workers will operate the line for 400min per day and must produce 300 products per day. A mechanized belt, moving at a speed of 1.25m/min, will transport the products between stations. Because of the variability in the time required to perform the assembly operations, it has been determined that the tolerance time should be 1.5 times the cycle time of the line. (a) Determine the ideal minimum number of workers on the line. (b) Use the Kilbridge and Wester method to balance the line. (c) Compute the balance delay for your solution in part (b). Q2 Solve the previous problem using the ranked positional weights method in part (b). Q3 Production rate for a certain assembled product is 47.5 units per hour. The assembly work content time =32min of direct manual labor. The line operates at 95% uptime. Ten workstations have two workers on opposite sides of the line so that both sides of the product can be worked on simultaneously. The remaining stations have one worker. Repositioning time lost by each worker is 0.2min/ cycle. It is known that the number of workers on the line is two more than the number required for perfect balance. Determine (a) number of workers, (b) number of workstations, (c) balance efficiency, and (d) average manning level. Q4 A single model assembly line is being planned to produce a consumer appliance at the rate of 200,000 units per year. The line will be operated 8 hours per shift, two shifts per day, five days per week, 50 weeks per year. Work content time =35.0min. For planning purposes, it is anticipated that the proportion uptime on the line will be 95%. Determine (a) average hourly production rate, (b) cycle time, and (c) theoretical minimum number of workers required on the line. (d) If the balance efficiency is 0.93 and the repositioning time =6sec, how many workers will actually be required Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started