Answered step by step

Verified Expert Solution

Question

1 Approved Answer

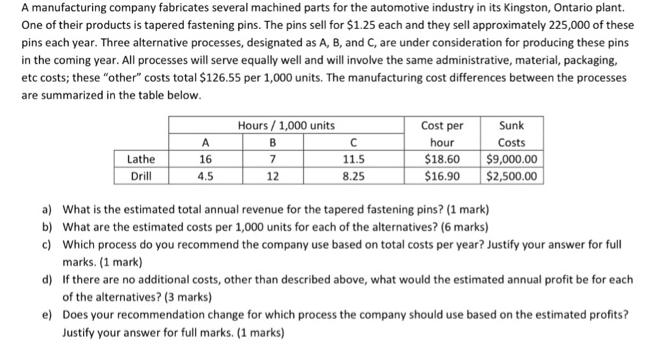

A manufacturing company fabricates several machined parts for the automotive industry in its Kingston, Ontario plant. One of their products is tapered fastening pins.

A manufacturing company fabricates several machined parts for the automotive industry in its Kingston, Ontario plant. One of their products is tapered fastening pins. The pins sell for $1.25 each and they sell approximately 225,000 of these pins each year. Three alternative processes, designated as A, B, and C, are under consideration for producing these pins in the coming year. All processes will serve equally well and will involve the same administrative, material, packaging, etc costs; these "other" costs total $126.55 per 1,000 units. The manufacturing cost differences between the processes are summarized in the table below. Lathe Drill A 16 4.5 Hours / 1,000 units B 7 12 C 11.5 8.25 Cost per hour $18.60 $16.90 Sunk Costs $9,000.00 $2,500.00 a) What is the estimated total annual revenue for the tapered fastening pins? (1 mark) b) What are the estimated costs per 1,000 units for each of the alternatives? (6 marks) c) Which process do you recommend the company use based on total costs per year? Justify your answer for full marks. (1 mark) d) If there are no additional costs, other than described above, what would the estimated annual profit be for each of the alternatives? (3 marks) e) Does your recommendation change for which process the company should use based on the estimated profits? Justify your answer for full marks. (1 marks)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

a The estimated total annual revenue for the tapered fastening pins is 281250 125 per pin 225000 pin...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started