Question

A manufacturing company produces two types of products: A and B. The company has agreed to deliver the products on the schedule shown in Table

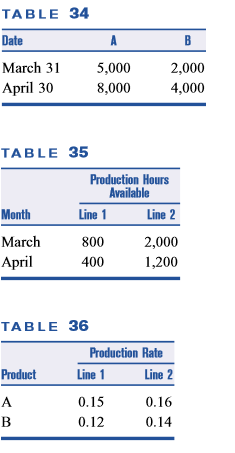

A manufacturing company produces two types of products: A and B. The company has agreed to deliver the products on the schedule shown in Table 34. The company has two assembly lines, 1 and 2, with the available production hours shown in Table 35. The production rates for each assembly line and product combination, in terms of hours per product, are shown in Table 36. It takes 0.15 hour to manufacture 1 unit of product A on line 1, and so on. It costs $5 per hour of line time to produce any product. The inventory carrying cost per month for each product is 20 per unit (charged on each months ending inventory). Currently, there are 500 units of A and 750 units of B in inventory. Management would like at least 1,000 units of each product in inventory at the end of April. Formulate an LP to determine the production schedule that minimizes the total cost incurred in meeting demands on time.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started