Question

A manufacturing company that makes dental drills was experiencing problems with a specific part on the production line. Management suspected a machining problem that resulted

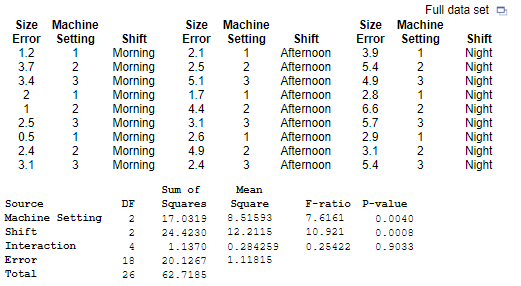

A manufacturing company that makes dental drills was experiencing problems with a specific part on the production line. Management suspected a machining problem that resulted in the length of the part varying outside of target specification. Two factors were?examined: the machine setting?(at three?levels) and the shift?(morning, afternoon, and?night). New hires were typically scheduled for night?shift, and management believed that their relative inexperience may also be contributing to the variation. Three parts were randomly selected and measured from each treatment combination. The deviation from specified size was measured in microns. The data and?two-way ANOVA results are shown. Complete parts a through d below.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started