Question: A mixture containing 50.0 wt% acetone and 50.0 wt% water is to be separated into two streams- one enriched in acetone, the other in

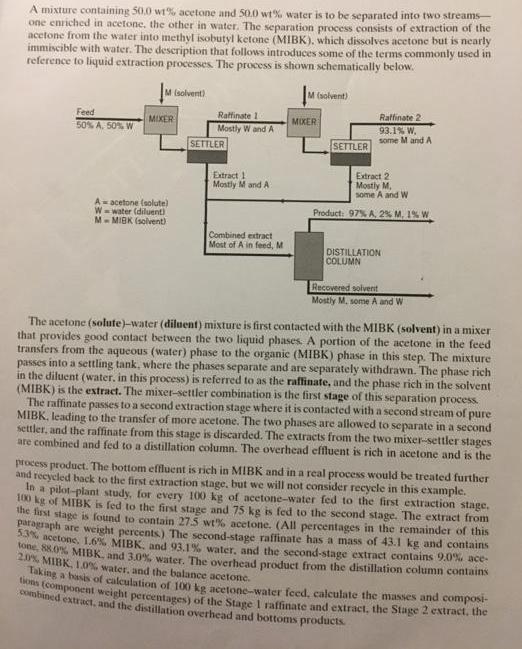

A mixture containing 50.0 wt% acetone and 50.0 wt% water is to be separated into two streams- one enriched in acetone, the other in water. The separation process consists of extraction of the acetone from the water into methyl isobutyl ketone (MIBK). which dissolves acetone but is nearly immiscible with water. The description that follows introduces some of the terms commonly used in reference to liquid extraction processes The process is shown schematically below. M (aolvent) (solvent) Raffinate 2 93.1% W, some M and A Feed Raffinate 1 MIXER MIXER 50% A, 50% W Mostly W and A SETTLER SETTLER Extract 2 Extract 1 Mostly M and A Mostly M, some A and W A=acetone (solute) W-water (diluent) M-MIBK (solvent) Producti 97% A, 2% M, 1% W Combined extract Most of A in feed, M DISTILLATION COLUMN Recovered solvent Mostly M. some A and W The acetone (solute)-water (diluent) mixture is first contacted with the MIBK (solvent) in a mixer that provides good contact between the two liquid phases. A portion of the acetone in the feed transfers from the aqueous (water) phase to the organic (MIBK) phase in this step. The mixture passes into a settling tank, where the phases separate and are separately withdrawn. The phase rich in the diluent (water, in this process) is referred to as the raffinate, and the phase rich in the solvent (MIBK) is the extract. The mixer-settler combination is the first stage of this separation process. The raffinate passes to a second extraction stage where it is contacted with a second stream of pure MIBK, leading to the transfer of more acetone. The two phases are allowed to separate in a second settler, and the raffinate from this stage is discarded. The extracts from the two mixer-settler stages are combined and fed to a distillation column. The overhead effluent is rich in acetone and is the process product. The bottom effluent is rich in MIBK and in a real process would be treated further and recycled back to the first extraction stage, but we will not consider recycle in this example. In a pilot-plant study, for every 100 kg of acetone-water fed to the first extraction stage, 100 kg of MIBK is fed to the first stage and 75 kg is fed to the second stage. The extract from he first stage is found to contain 27.5 wt% acetone. (All percentages in the remainder of this Paragraph are weight percents) The second-stage raffinate has a mass of 43.1 kg and contains G acetone, 1.6% MIBK, and 93.1% water, and the second-stage extract contains 9.0% ace- he. S8.O% MIBK, and 3.0% water. The overhead product from the distillation column contains 20% MIBK, 1.0% water, and the balance acetone. taking a basis of calculation of 100 ke acetone-water fced, calculate the masses and composi- s (component weight percentages) of the Stage I raffinate and extract, the Stage 2 extract. the combined extract, and the distillation overhcad and bottoms products

Step by Step Solution

3.39 Rating (168 Votes )

There are 3 Steps involved in it

Feed in 1 st stage 100 ... View full answer

Get step-by-step solutions from verified subject matter experts