Answered step by step

Verified Expert Solution

Question

1 Approved Answer

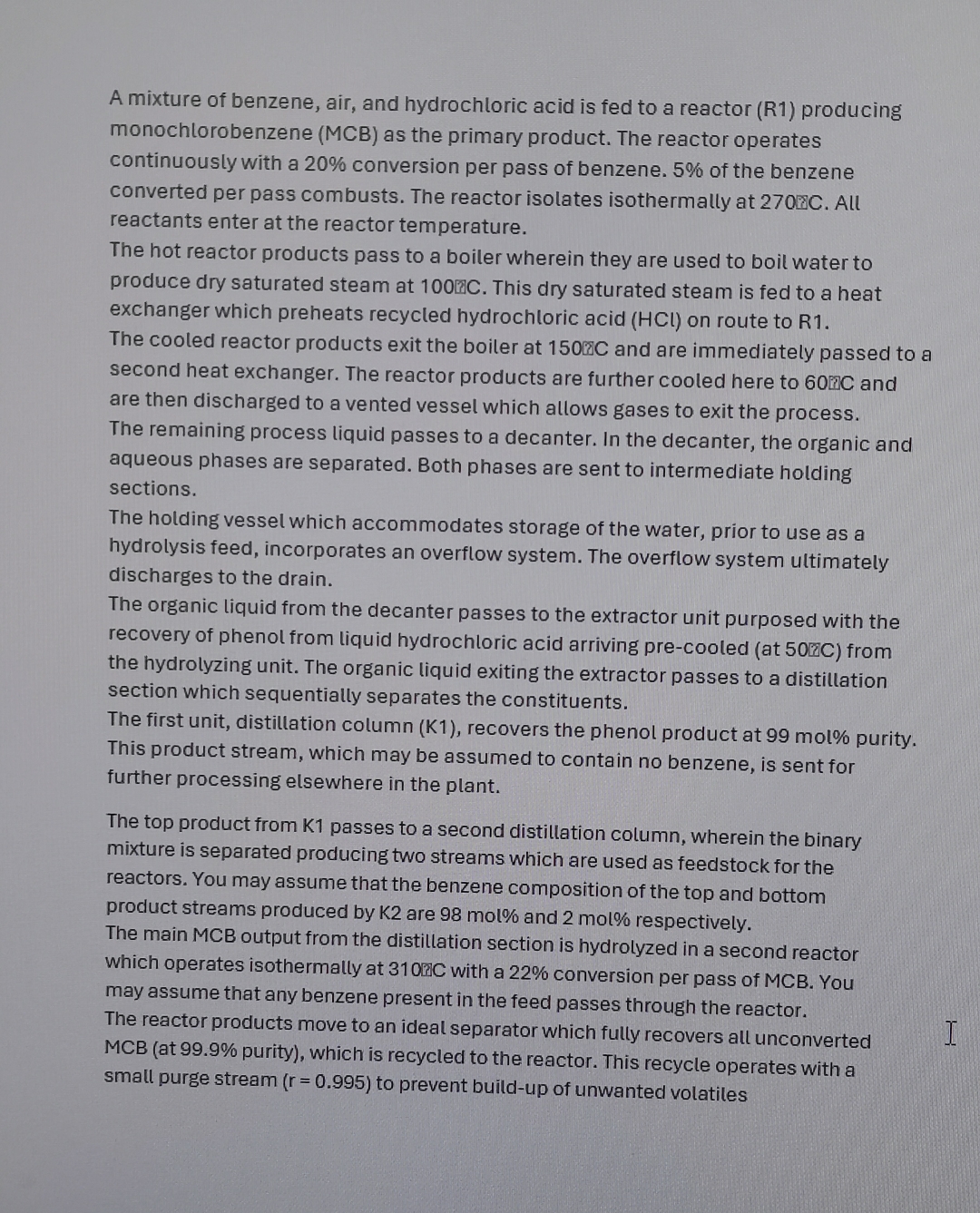

A mixture of benzene, air, and hydrochloric acid is fed to a reactor ( R 1 ) producing monochlorobenzene ( MCB ) as the primary

A mixture of benzene, air, and hydrochloric acid is fed to a reactor R producing monochlorobenzene MCB as the primary product. The reactor operates continuously with a conversion per pass of benzene. of the benzene converted per pass combusts. The reactor isolates isothermally at All reactants enter at the reactor temperature.

The hot reactor products pass to a boiler wherein they are used to boil water to produce dry saturated steam at This dry saturated steam is fed to a heat exchanger which preheats recycled hydrochloric acid on route to The cooled reactor products exit the boiler at and are immediately passed to a second heat exchanger. The reactor products are further cooled here to and are then discharged to a vented vessel which allows gases to exit the process. The remaining process liquid passes to a decanter. In the decanter, the organic and aqueous phases are separated. Both phases are sent to intermediate holding sections.

The holding vessel which accommodates storage of the water, prior to use as a hydrolysis feed, incorporates an overflow system. The overflow system ultimately discharges to the drain.

The organic liquid from the decanter passes to the extractor unit purposed with the recovery of phenol from liquid hydrochloric acid arriving precooled at C from the hydrolyzing unit. The organic liquid exiting the extractor passes to a distillation section which sequentially separates the constituents.

The first unit, distillation column K recovers the phenol product at mol purity. This product stream, which may be assumed to contain no benzene, is sent for further processing elsewhere in the plant.

The top product from K passes to a second distillation column, wherein the binary mixture is separated producing two streams which are used as feedstock for the reactors. You may assume that the benzene composition of the top and bottom product streams produced by are mol and mol respectively.

The main MCB output from the distillation section is hydrolyzed in a second reactor which operates isothermally at With a conversion per pass of MCB You may assume that any benzene present in the feed passes through the reactor. The reactor products move to an ideal separator which fully recovers all unconverted MCB at purity which is recycled to the reactor. This recycle operates with a small purge stream to prevent buildup of unwanted volatiles

Can you help me to drww this basic process flows digraam thanks for your patience

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started