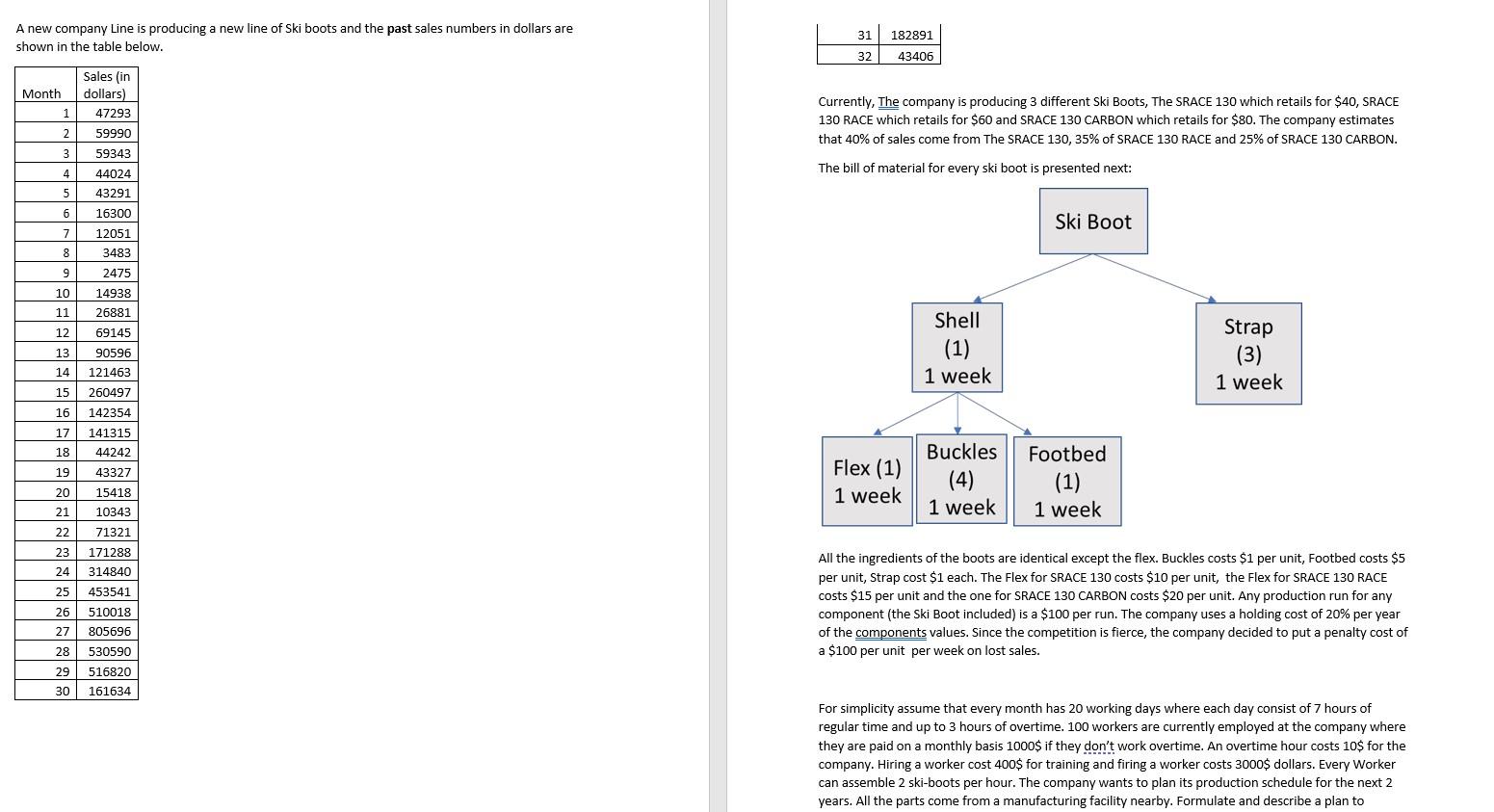

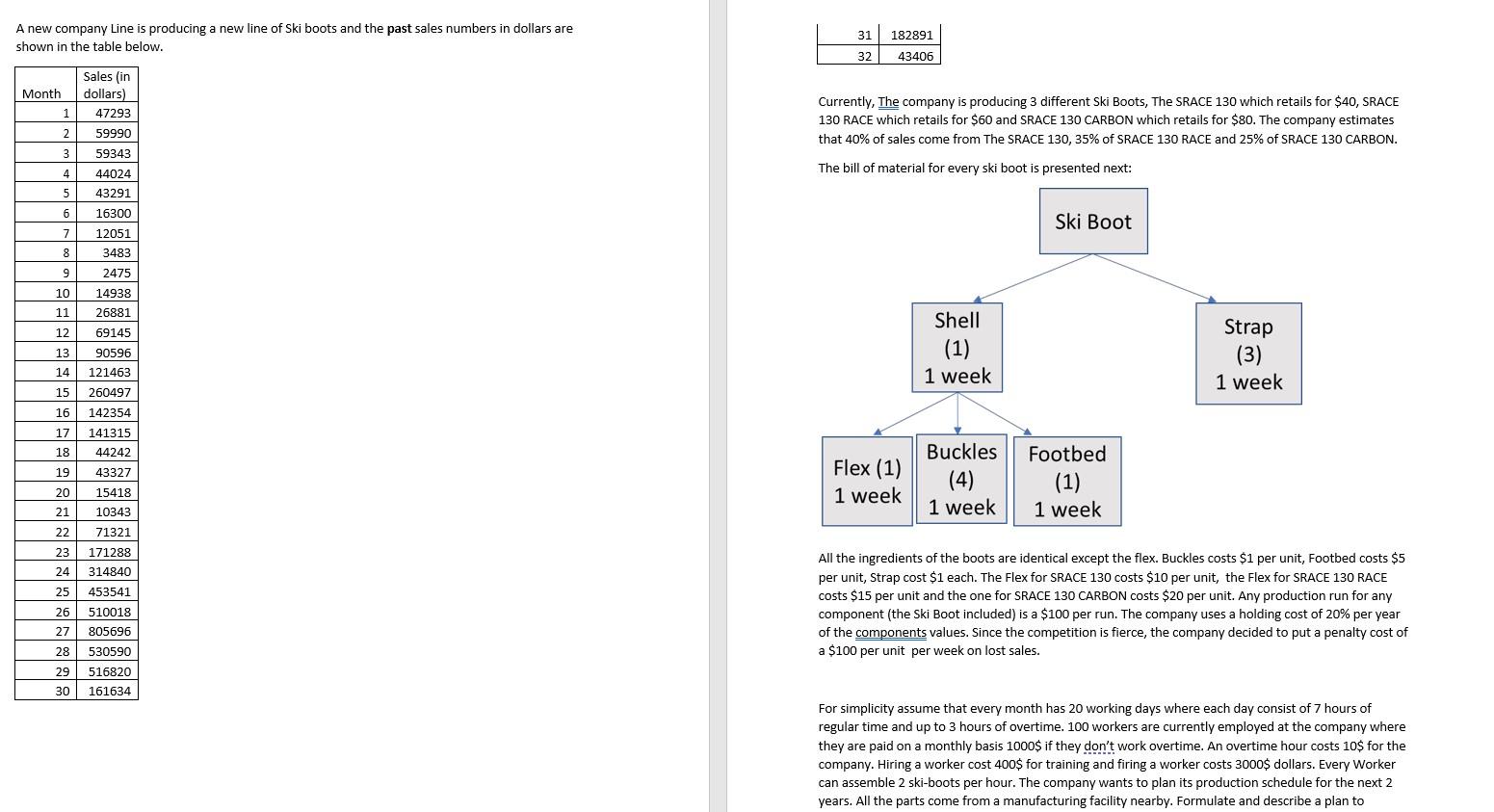

A new company Line is producing a new line of ski boots and the past sales numbers in dollars are shown in the table below. 31 182891 32 43406 Month 1 2 Sales (in dollars) 47293 59990 59343 Currently, the company is producing 3 different Ski Boots, The SRACE 130 which retails for $40, SRACE 130 RACE which retails for $60 and SRACE 130 CARBON which retails for $80. The company estimates that 40% of sales come from The SRACE 130, 35% of SRACE 130 RACE and 25% of SRACE 130 CARBON. 3 4 The bill of material for every ski boot is presented next: 5 44024 43291 16300 6 Ski Boot 7 12051 3483 8 9 2475 10 11 12 13 Shell (1) 1 week Strap (3) 1 week 14 15 16 17 18 19 14938 26881 69145 90596 121463 260497 142354 141315 44242 43327 15418 10343 71321 171288 314840 453541 510018 805696 530590 516820 161634 Flex (1) 1 week Buckles (4) 1 week Footbed (1) 1 week 20 21 22 23 24 25 26 All the ingredients of the boots are identical except the flex. Buckles costs $1 per unit, Footbed costs $5 per unit, Strap cost $1 each. The Flex for SRACE 130 costs $10 per unit, the Flex for SRACE 130 RACE costs $15 per unit and the one for SRACE 130 CARBON costs $20 per unit. Any production run for any component (the Ski Boot included) is a $100 per run. The company uses a holding cost of 20% per year of the components values. Since the competition is fierce, the company decided to put a penalty cost of a $100 per unit per week on lost sales. 27 28 29 30 For simplicity assume that every month has 20 working days where each day consist of 7 hours of regular time and up to 3 hours of overtime. 100 workers are currently employed at the company where they are paid on a monthly basis 1000$ if they don't work overtime. An overtime hour costs 10$ for the company. Hiring a worker cost 400$ for training and firing a worker costs 3000$ dollars. Every Worker can assemble 2 ski-boots per hour. The company wants to plan its production schedule for the next 2 years. All the parts come from a manufacturing facility nearby. Formulate and describe a plan to A new company Line is producing a new line of ski boots and the past sales numbers in dollars are shown in the table below. 31 182891 32 43406 Month 1 2 Sales (in dollars) 47293 59990 59343 Currently, the company is producing 3 different Ski Boots, The SRACE 130 which retails for $40, SRACE 130 RACE which retails for $60 and SRACE 130 CARBON which retails for $80. The company estimates that 40% of sales come from The SRACE 130, 35% of SRACE 130 RACE and 25% of SRACE 130 CARBON. 3 4 The bill of material for every ski boot is presented next: 5 44024 43291 16300 6 Ski Boot 7 12051 3483 8 9 2475 10 11 12 13 Shell (1) 1 week Strap (3) 1 week 14 15 16 17 18 19 14938 26881 69145 90596 121463 260497 142354 141315 44242 43327 15418 10343 71321 171288 314840 453541 510018 805696 530590 516820 161634 Flex (1) 1 week Buckles (4) 1 week Footbed (1) 1 week 20 21 22 23 24 25 26 All the ingredients of the boots are identical except the flex. Buckles costs $1 per unit, Footbed costs $5 per unit, Strap cost $1 each. The Flex for SRACE 130 costs $10 per unit, the Flex for SRACE 130 RACE costs $15 per unit and the one for SRACE 130 CARBON costs $20 per unit. Any production run for any component (the Ski Boot included) is a $100 per run. The company uses a holding cost of 20% per year of the components values. Since the competition is fierce, the company decided to put a penalty cost of a $100 per unit per week on lost sales. 27 28 29 30 For simplicity assume that every month has 20 working days where each day consist of 7 hours of regular time and up to 3 hours of overtime. 100 workers are currently employed at the company where they are paid on a monthly basis 1000$ if they don't work overtime. An overtime hour costs 10$ for the company. Hiring a worker cost 400$ for training and firing a worker costs 3000$ dollars. Every Worker can assemble 2 ski-boots per hour. The company wants to plan its production schedule for the next 2 years. All the parts come from a manufacturing facility nearby. Formulate and describe a plan to