Question

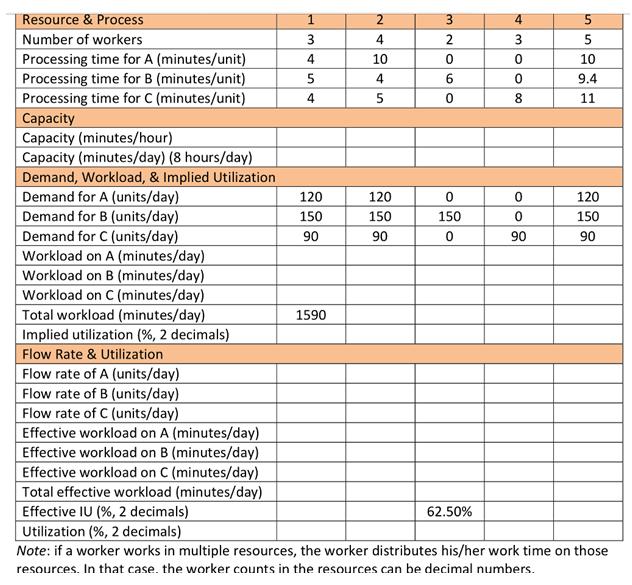

A process is composed of five resources working on products A, B, and C for eight hours a day. The table below summarizes the situation.

A process is composed of five resources working on products A, B, and C for eight hours a day. The table below summarizes the situation. You would need to choose a minute of work as the common flow unit for all products and resources. In addition, you need to explain and show your calculations steps. Some cells are prefilled for your reference. Use 2 decimal places.

On the supply side, we know how many workers are in charge of each resource and the processing time in minutes per unit for each product at each resource. Zero processing time means the product of interest does not go through the corresponding resource at all. Besides, assume that inputs are always sufficient.

On the demand side, we know demands for products A, B, and C per day as follows:

‐ Demand for A: 120 units per day,

‐ Demand for B: 150 units per day,

‐ Demand for C: 90 units per day.

In addition, we assume a fixed product mix of A: B: C = 4:5:3.

(a)[2] Draw a process flow diagram of the process, assuming that there are buffers between resources. Make sure to have process boundaries.

(b)[1] Find two measures of capacity for each resource as in the table.

(c)[1] Find total workload on each resource.

(d)[1] Find implied utilizations of individual resources. Draw the implied utilization profile.

(e)[1] Find the bottleneck and the demand‐acceptance ratio (DAR = 1/IU of the bottleneck).

(f)[1] based on the demand‐acceptance ratio; find the effective flow rates of A, B, and C. Explain.

(g)[1] Find total effective workload and effective IU on each resource.

(h)[1] Find utilizations of individual resources. Draw the utilization profile.

(I)[1] Process analysis is for designing and improving business processes! By looking at the implied utilization and utilization profiles, propose one way to reallocate workers among the resources so as to increase the flow rates of products A, B, and C. For this part, you should try to implement the table in Excel and reallocate workers in your Excel template.

Resource & Process Number of workers Processing time for A (minutes/unit) Processing time for B (minutes/unit) Processing time for C (minutes/unit) Capacity Capacity (minutes/hour) Capacity (minutes/day) (8 hours/day) Demand, Workload, & Implied Utilization Demand for A (units/day) Demand for B (units/day) Demand for C (units/day) Workload on A (minutes/day) Workload on B (minutes/day) Workload on C (minutes/day) Total workload (minutes/day) Implied utilization (%, 2 decimals) Flow Rate & Utilization Flow rate of A (units/day) Flow rate of B (units/day) Flow rate of C (units/day) Effective workload on A (minutes/day) Effective workload on B (minutes/day) Effective workload on C (minutes/day) Total effective workload (minutes/day) Effective IU (%, 2 decimals) Utilization (%, 2 decimals) Note: if a worker works in multiple resources, the worker distributes his/her work time on those 1 3. 4 5. 3 4 2 3 5 10 10 5 4 6. 9.4 4 5 8. 11 120 120 120 150 150 150 150 90 90 90 90 1590 62.50% resources. In that case. the worker counts in the resources can be decimal numbers.

Step by Step Solution

3.47 Rating (160 Votes )

There are 3 Steps involved in it

Step: 1

Resource process 1 2 3 4 5 Number pf workers 45 3 4 35 6 Processing time for A minutesunitworker 0 5 0 4 8 Processing time for B minutesunitworker 5 5 ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started