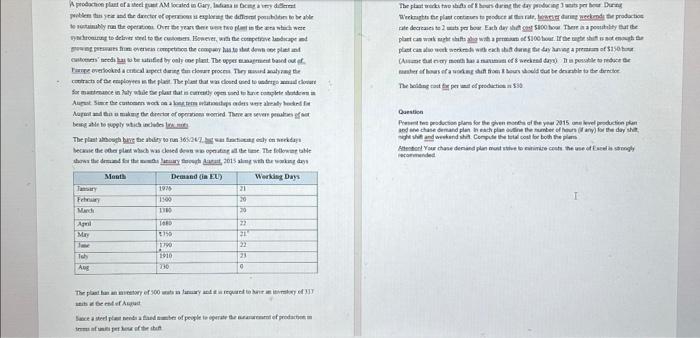

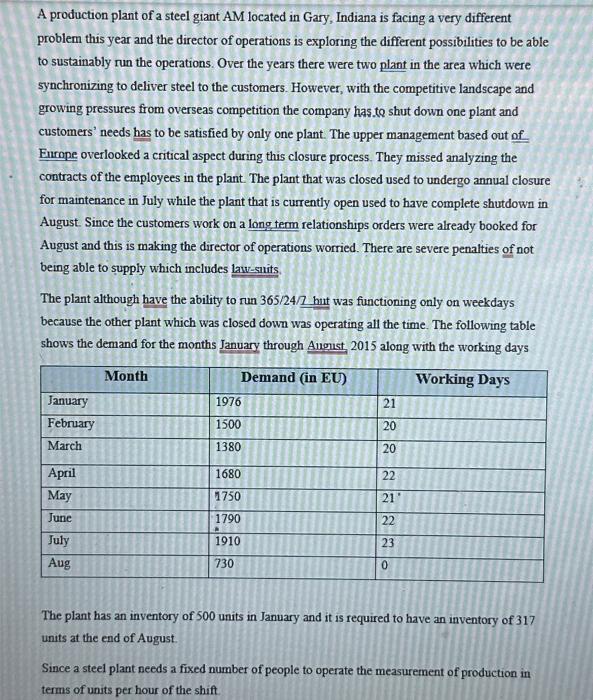

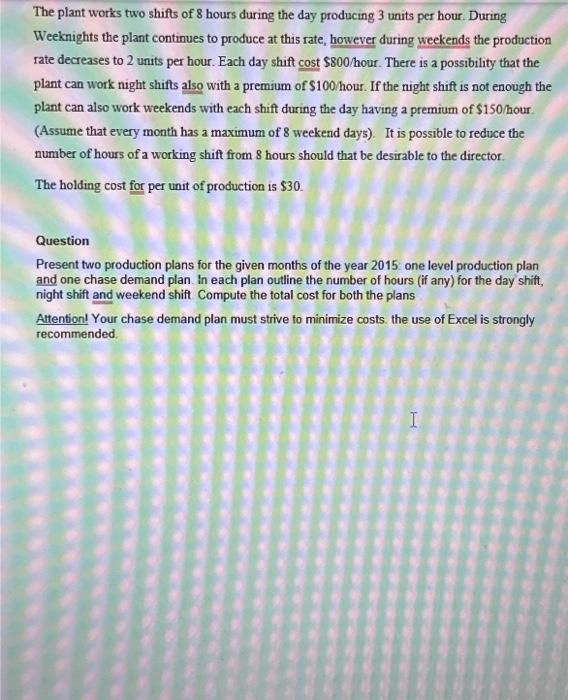

A production plant of a steel giant AM located in Gary, Indiana is facing a very different problem this year and the director of operations is exploring the different possibilities to be able to sustainably run the operations. Over the years there were two plant in the area which were synchronizing to deliver steel to the customers. However, with the competitive landscape and growing pressures from overseas competition the company has to shut down one plant and customers' needs has to be satisfied by only one plant. The upper management based out of Eurnpe overlooked a critical aspect during this closure process. They missed analyzing the contracts of the employees in the plant. The plant that was closed used to undergo annual closure for maintenance in July while the plant that is currently open used to have complete shutdown in August. Since the customers work on a long term relationships orders were already booked for August and this is making the director of operations worried. There are severe penalties of not being able to supply which includes law-snits. The plant although have the ability to run 365/24/2 hit was functioning only on weekdays because the other plant which was closed down was operating all the time. The following table shows the demand for the months January through Angist, 2015 along with the working days The plant has an inventory of 500 units in January and it is required to have an inventory of 317 units at the end of August. Since a steel plant needs a fixed number of people to operate the measurement of production in terms of units per hour of the shift. Question inits a be ent of Abuct The plant works two shifts of 8 hours during the day producing 3 units per hour. During Weeknights the plant continues to produce at this rate, however during weekends the production rate decreases to 2 units per hour. Each day shift cost $800/ hour. There is a possibility that the plant can work night shifts also with a premium of $100 hour. If the night shift is not enough the plant can also work weekends with each shift during the day having a premium of $150 hour (Assume that every month has a maximum of 8 weekend days). It is possible to reduce the number of hours of a working shift from 8 hours should that be desirable to the director. The holding cost for per unit of production is $30. Question Present two production plans for the given months of the year 2015: one level production plan and one chase demand plan. In each plan outline the number of hours (if any) for the day shift, night shift and weekend shift Compute the total cost for both the plans Altention! Your chase demand plan must strive to minimize costs. the use of Excel is strongly recommended