a quick response would be hugely appreciated, thanks much!

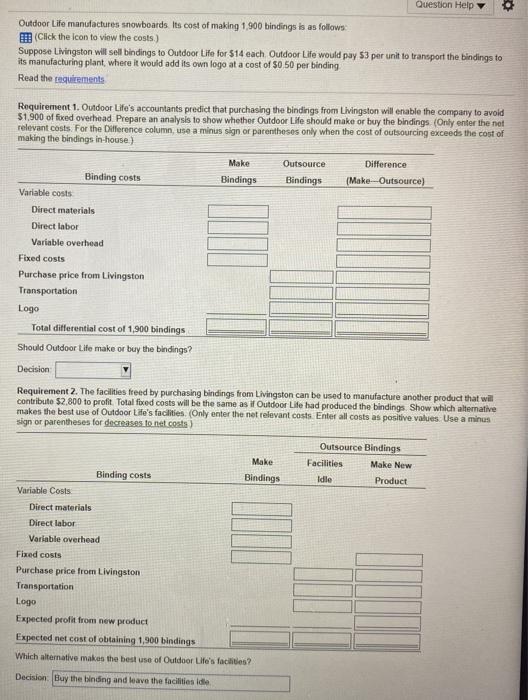

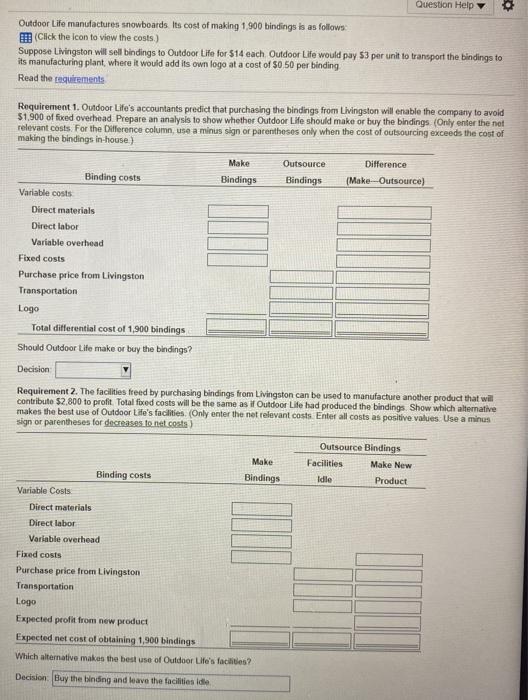

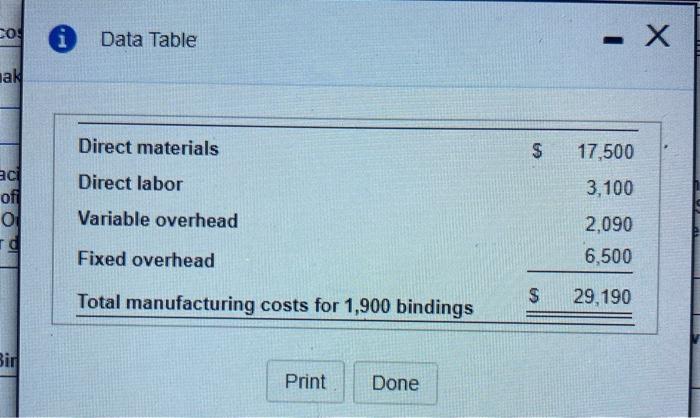

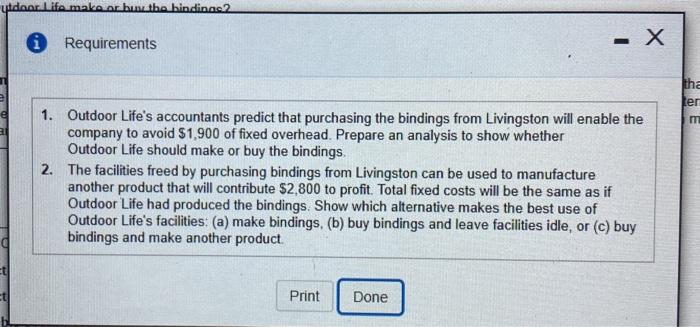

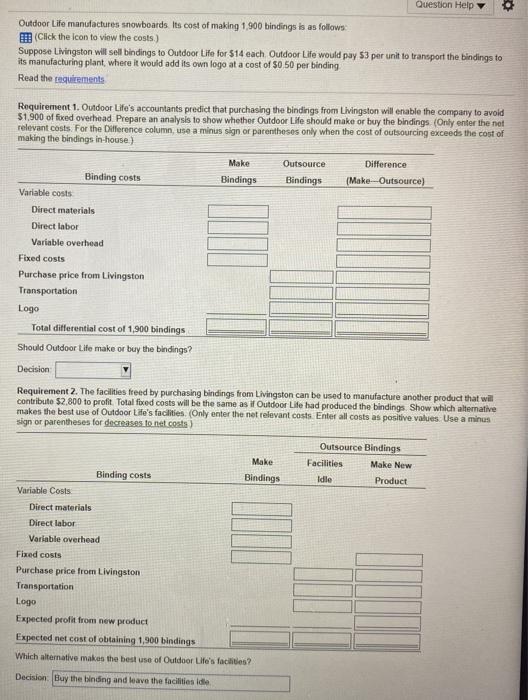

Question Help Outdoor Life manufactures snowboards. Its cost of making 1900 bindings is as follows: (Click the icon to view the costs) Suppose Livingston will sell bindings to Outdoor Life for 514 each Outdoor Life would pay $3 per unit to transport the bindings to its manufacturing plant, where it would add its own logo at a cost of $0.50 per binding Read the requirements Requirement 1. Outdoor Life's accountants predict that purchasing the bindings from Livingston will enable the company to avoid $1,900 of fixed overhead Prepare an analysis to show whether Outdoor Life should make or buy the bindings (Only enter the net relevant costs. For the Difference column, use a minus sign or parentheses only when the cost of outsourcing exceeds the cost of making the bindings in-house.) Make Outsource Difference Binding costs Bindings Bindings (Make-Outsource) Variable costs Direct materials Direct labor Variable overhead Fixed costs Purchase price from Livingston Transportation Logo Total differential cost of 1,900 bindings Should Outdoor Life make or buy the bindings? Decision Requirement 2. The facilities freed by purchasing bindings from Livingston can be used to manufacture another product that will contribute 52,800 to profit. Totalfixed costs will be the same as if Outdoor Life had produced the bindings. Show which alternative makes the best use of Outdoor Life's facilities. (Only enter the net relevant costs Enter all costs as positive values. Use a minus sign or parentheses for decreases to net costs Outsource Bindings Make Facilities Make New Binding costs Bindings Idile Product Variable Costs Direct materials Direct labor Variable overhead Fixed costs Purchase price from Livingston Transportation Logo Expected profit from new product Expected net cost of obtaining 1,900 bindings Which alternative makes the best use of Outdoor Life's facilities? Decision Buy the binding and leave the facilities ide Question Help Outdoor Life manufactures snowboards. Its cost of making 1900 bindings is as follows: (Click the icon to view the costs) Suppose Livingston will sell bindings to Outdoor Life for 514 each Outdoor Life would pay $3 per unit to transport the bindings to its manufacturing plant, where it would add its own logo at a cost of $0.50 per binding Read the requirements Requirement 1. Outdoor Life's accountants predict that purchasing the bindings from Livingston will enable the company to avoid $1,900 of fixed overhead Prepare an analysis to show whether Outdoor Life should make or buy the bindings (Only enter the net relevant costs. For the Difference column, use a minus sign or parentheses only when the cost of outsourcing exceeds the cost of making the bindings in-house.) Make Outsource Difference Binding costs Bindings Bindings (Make-Outsource) Variable costs Direct materials Direct labor Variable overhead Fixed costs Purchase price from Livingston Transportation Logo Total differential cost of 1,900 bindings Should Outdoor Life make or buy the bindings? Decision Requirement 2. The facilities freed by purchasing bindings from Livingston can be used to manufacture another product that will contribute 52,800 to profit. Totalfixed costs will be the same as if Outdoor Life had produced the bindings. Show which alternative makes the best use of Outdoor Life's facilities. (Only enter the net relevant costs Enter all costs as positive values. Use a minus sign or parentheses for decreases to net costs Outsource Bindings Make Facilities Make New Binding costs Bindings Idile Product Variable Costs Direct materials Direct labor Variable overhead Fixed costs Purchase price from Livingston Transportation Logo Expected profit from new product Expected net cost of obtaining 1,900 bindings Which alternative makes the best use of Outdoor Life's facilities? Decision Buy the binding and leave the facilities ide