Question: A S E AUTOMOTIVE BUILDERS, INC.: THE STANHOPE PROJECT Jack Meredith It was a cold, gray October day as Jim Wickes pulled his car into

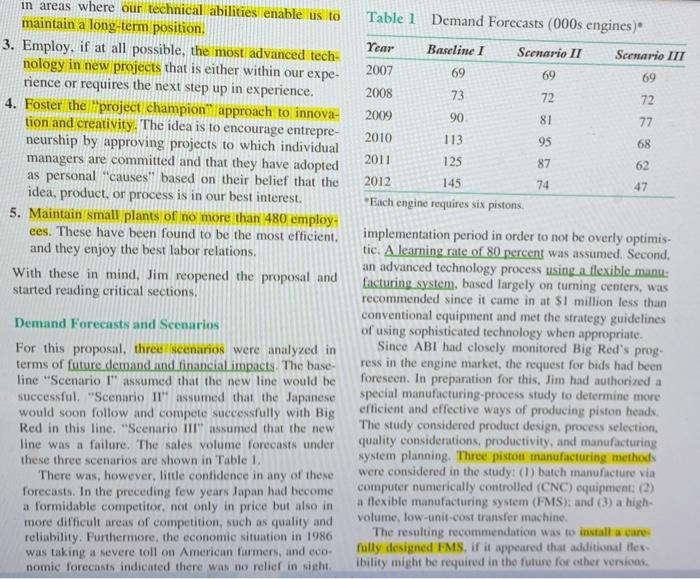

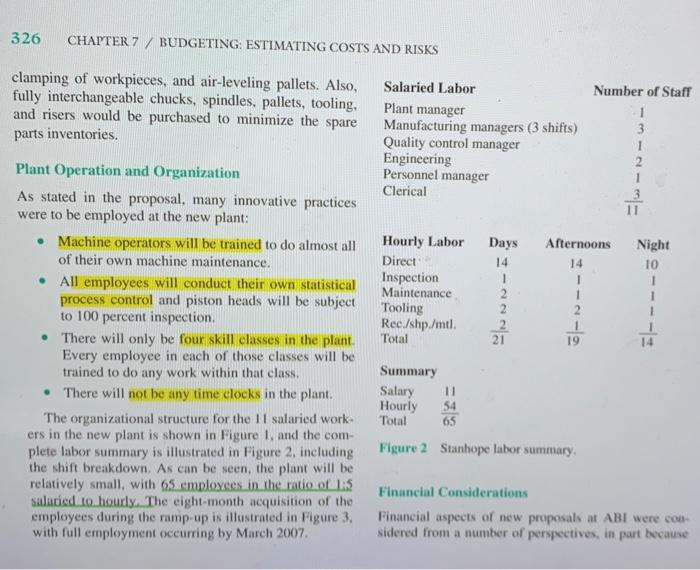

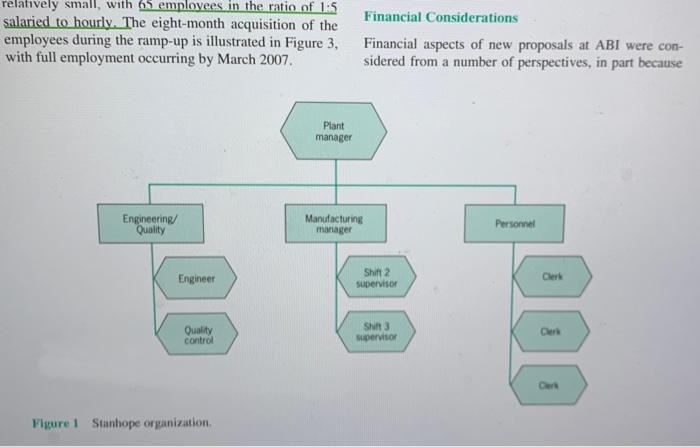

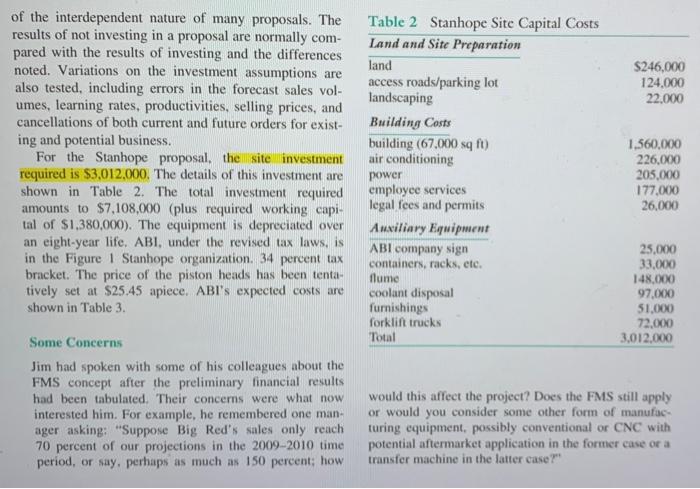

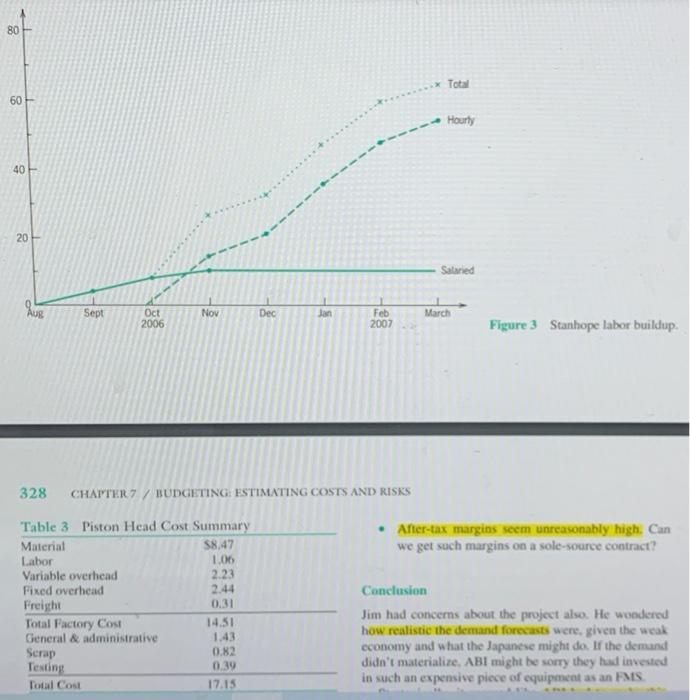

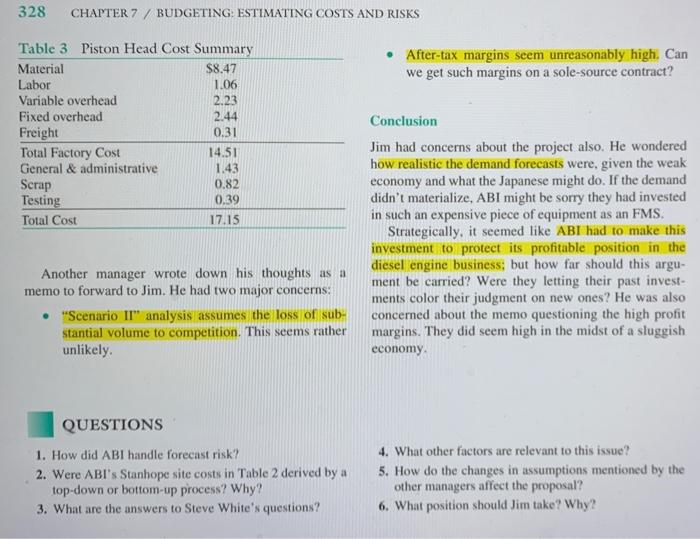

A S E AUTOMOTIVE BUILDERS, INC.: THE STANHOPE PROJECT Jack Meredith It was a cold, gray October day as Jim Wickes pulled his car into ABI's corporate offices parking lot in suburban Detroit. The leaves, in yellows and browns, swirled around his feet as he walked into the wind toward the lobby. "Good morning, Mr. Wickes," said his secretary as he came into the office. "That proposal on the Stanhope proj- ect just arrived a minute ago. It's on your desk." "Good morning, Debbie. Thanks. I've been anxious to see it." This was the day Jim had scheduled to review next year's supplemental capital request and he didn't want any interruptions as he scrutinized the details of the flexible manufacturing project planned for Stanhope. Iowa. The Stanhope proposal, compiled by Ann Wil- liamson, PM and managerial "champion" of this effort. looked like just the type of project to fit ABI's new strategic plan, but there was a large element of risk in the project. Before recommending the project to Steve White, executive vice president of ABI, Jim wanted to review all the details one more time. History of ABI ABI started operations as the Farm Equipment Com- pany just after the First World War. Employing new *Reprinted with permission. Copyright JR Meredith 324 CHAPTER 7 / BUDGETING: ESTIMATING COSTS AND RISKS technology to produce diesel engine parts for tractors, the firm flourished with the growth of farming and became a multimillion dollar company by 1940. ABI had two plants producing diesel engine com ponents for other manufacturers and believed they had a competitive edge in engineering of this type. These technology to produce diesel engine parts for tractors, the firm flourished with the growth of farming and became a multimillion dollar company by 1940. During the Second World War, the firm switched to producing tank and truck parts in volume for the mili- tary. At the war's end, the firm converted its equipment to the production of automotive parts for the expand- ing automobile industry. To reflect this major change in their product line, the company was renamed Automo- tive Builders, Inc. (ABI), though they remained a major supplier to the farm equipment market. A Major Capital Project The farm equipment industry in the 1980s had been doing well, but there were some disturbing trends, Japa- nese manufacturers had entered the industry and were beginning to take a significant share of the domestic market. More significantly, domestic labor costs were significantly higher than overseas and resulted in price disadvantages that couldn't be ignored any longer. Per- haps most important of all, quality differences between American and Japanese farm equipment, including trac- tors, were becoming quite noticeable. To improve the quality and costs of their incoming materials, in the 1990s many of the domestic tractor manufacturers started single-sourcing a number of their tractor components. By the 2000s, they had gained bet- ter control over both quality and cost, and were able to coordinate delivery schedules more easily. Recently, one of the major tractor engine manu- facturers, code-named "Big Red" within ABI, let its suppliers know that it was interested in negotiating a contract for a possible 100 percent sourcing of 17 ver- sions of special piston heads destined for a new line of high-efficiency tractor engines expected to replace the ABI had two plants producing diesel engine com- ponents for other manufacturers and believed they had a competitive edge in engineering of this type. These plants, however, could not accommodate the volume Big Red expected for the new engine. Big Red insisted at their negotiations that a 100 percent supplier be able to meet peak capacity at their assembly plant for this new line. As Jim reviewed the proposal, he decided to refer back to the memos that restated their business strat- egy and started them thinking about a new lowa plant located in the heart of the farm equipment industry for this project. In addition, Steve White had asked the fol- lowing basic, yet rather difficult questions about the proposal at their last meeting, and Jim wanted to be sure he had them clearly in mind as he reviewed the files. ABI is already achieving an excellent return on investment (ROI). Won't this investment simply tend to dilute it? Will the cost in new equipment be returned by an equivalent reduction in labor? Where's the payoff? What asset protection is there? This proposal requires an investment in new facilities before knowing whether a long-term contract will be procured to reimburse us for our investment. Does this proposal maximize ROI, sales poten. tial, or total profit? To address these questions adequately, Jim decided to recheck the expected after tax profits and average rate of retum (based on sales.of 70.000 engines px year when he reached the financial portion of the pro- posals. These figures should give a clear indication of the "quality" of the investment. There were, however, the framewt win - To address these questions adequately, Jim decided to recheck the expected after-tax profits and average rate of return (based on sales of 70.000 engines per year) when he reached the financial portion of the pro- posals. These figures should give a clear indication of the "quality" of the investment. There were, however, other aspects of capital resource allocation to consider besides the financial elements. One of these was the new business strategy of the firm, as recently articulated by ABI's executive committee. delivery schedules more easily. Recently, one of the major tractor engine manu- facturers, code-named "Big Red" within ABI, let its suppliers know that it was interested in negotiating a contract for a possible 100 percent sourcing of 17 ver- sions of special piston heads destined for a new line of high-efficiency tractor engines expected to replace the current conventional engines in both new and existing tractors. These were all six-cylinder diesel engines and thus would require six pistons each. This put ABI in an interesting situation. If they failed to bid on this contract, they would be inviting compe- tition into their very successful and profitable diesel engine parts business. Thus, to protect their existing suc- cessful business, and to pursue more such business, ABI seemed required to bid on this contract. Should ABI be successful in their bid, this would result in 100 percent sourcing in both the original equipment market (OEM) as well as the replacement market with its high margins. Furthermore, the high investment required to pro- duce these special pistons at ABI's costs would virtually rule out future competition. The Business Strategy A number of elements of ABI's business strategy were directly relevant to this proposal. Jim took out a note pad to jot down each of them and assign them a priority as follows: 1. Bid only on good margin products that have the poten- tial for maintaining their margins over a long term. 2. Pursue only new products whose design or produe. tion process is of a proprietary nature and that exist in areas where our technical abilities enable us to maintain a long-term position, 3. Employ, if at all possible, the most advanced tech- nology in new projects that is either within our expe- rience or requires the next step up in experience. 4. Foster the project champion approach to innova- tion and creativity. The idea is to encourage entrepre- neurship by approving projects to which individual managers are committed and that they have adopted as personal "causes" based on their belief that the idea, product, or process is in our best interest. 5. Maintain small plants of no more than 480 employ ees. These have been found to be the most efficient. and they enjoy the best labor relations. With these in mind, Jim reopened the proposal and started reading critical sections, Table 1 Demand Forecasts (000s engines) Year Baseline 1 Scenario II Scenario III 2007 69 69 69 2008 73 72 72 2009 90 81 77 2010 113 95 68 2011 125 87 62 2012 145 74 47 Each engine requires six pistons implementation period in order to not be overly optimis- tic. A learning rate of 80 percent was assumed. Second, an advanced technology process using a flexible manu: facturing system, based largely on turning centers, was recommended since it came in at $1 million less than conventional equipment and met the strategy guidelines of using sophisticated technology when appropriate. Since ABI had closely monitored Big Red's prog. ress in the engine market, the request for bids had been foreseen. In preparation for this. Jim had authorized a special manufacturing process study to determine more efficient and effective ways of producing piston heads. The study considered product design, process selection, quality considerations, productivity, and manufacturing system planning. Three piston manufacturing methods were considered in the study: (1) batch manufacture via computer numerically controlled (CNC) equipment (2) a flexible manufacturing system (FMS) and (3) a high- volume, low-unit-cost transfer machine The resulting recommendation was to install wears fully designed FMS. if it appeared that additional flex ibility might be required in the future for other versions, Demand Forecasts and Scenarios For this proposal, thred scenarios were analyzed in terms of future demand and financial impacts. The base- line "Scenario I assumed that the new line would be successful. "Scenario II assumed that the Japanese would soon follow and compete successfully with Big Red in this line. "Scenario III" assumed that the new line was a failure. The sales volume forecasts under these three scenarios are shown in Table 1 There was, however, little confidence in any of these forecasts. In the preceding few years Japan had become a formidable competitor, not only in price but also in more difficult areas of competition, such as quality and reliability. Furthermore, the economic situation in 1986 was taking a severe toll on American farmers, and eco- nomic forecasts indicated there was no relier in sieht Demand Forecasts and Scenarios For this proposal, three scenarios were analyzed in terms of future demand and financial impacts. The base- line "Scenario l' assumed that the new line would be successful. "Scenario I assumed that the Japanese would soon follow and compete successfully with Big Red in this line. "Scenario III assumed that the new line was a failure. The sales volume forecasts under these three scenarios are shown in Table 1. There was, however, little confidence in any of these forecasts. In the preceding few years Japan had become a formidable competitor, not only in price but also in more difficult areas of competition, such as quality and reliability. Furthermore, the economic situation in 1986 was taking a severe toll on American farmers, and eco- nomic forecasts indicated there was no relief in sight. Thus, as stated in the proposal: The U.S. farm market will be a difficult battle- ground for world farm equipment manufacturers and any forecast of a particular engine's poten- tial in this market must be considered as par- ticularly risky. How much risk do we want to accept? Every effort should be made to minimize our exposure on this investment and maximize our flexibility conventional equipment and met the strategy guidelines of using sophisticated technology when appropriate. Since ABI had closely monitored Big Red's prog- ress in the engine market, the request for bids had been foreseen. In preparation for this, Jim had authorized a special manufacturing process study to determine more efficient and effective ways of producing piston heads. The study considered product design, process selection, quality considerations, productivity, and manufacturing system planning. Three piston manufacturing methods were considered in the study: (1) batch manufacture via computer numerically controlled (CNC) equipment; (2) a flexible manufacturing system (FMS); and (3) a high- volume, low-unit-cost transfer machine. The resulting recommendation was to install a care- fully designed FMS, if it appeared that additional flex- ibility might be required in the future for other versions, or even other manufacturers. Though such a system would be expensive, the volume of production over the FMS's longer lifetime would offset that expense. Four preferred machine builders were contacted for equipment specifications and bids. It was ABI's plan to work closely with the selected vendor in designing and installing the equipment, thus building quality and reli- ability into both the product and the process and leam- ing about the equipment at the same time. To add further flexibility for the expensive machin. ery, all design features that would facilitate retool or changeover to other products were incorporated. For example, the machining centers would also be capable of machining other metals, such as aluminum or nodu- lar iron, and would be fitted with variable feed and speed motors, feed-force monitors, pressure-controlled Manufacturing Plan The proposal stressed two primary aspects of the manu. facturing process. First, a learning curve was employed in calculating production during the 1000 unit ramp-up 326 CHAPTER 7 / BUDGETING: ESTIMATING COSTS AND RISKS clamping of workpieces, and air-leveling pallets. Also, fully interchangeable chucks, spindles, pallets, tooling, and risers would be purchased to minimize the spare parts inventories. Salaried Labor Plant manager Manufacturing managers (3 shifts) Quality control manager Engineering Personnel manager Clerical Number of Staff 1 3 1 2 1 11 Night 10 Hourly Labor Direct Inspection Maintenance Tooling Rec./shp./mtl. Total Days 14 1 2 2 2 Afternoons 14 1 1 2 1 1 14 Plant Operation and Organization As stated in the proposal, many innovative practices were to be employed at the new plant: Machine operators will be trained to do almost all of their own machine maintenance. All employees will conduct their own statistical process control and piston heads will be subject to 100 percent inspection There will only be four skill classes in the plant Every employee in each of those classes will be trained to do any work within that class. There will not be any time clocks in the plant. The organizational structure for the 11 salaried work- ers in the new plant is shown in Figure 1. and the com- plete labor summary is illustrated in Figure 2. including the shift breakdown. As can be seen, the plant will be relatively small, with 65 employees in the ratio of 15 salaried to hourly. The eight-month acquisition of the employees during the ramp-up is illustrated in Figure 3. with full employment occurring by March 2007 Summary Salary 11 Hourly 54 Total 65 Figure 2 Stanhope labor summary, Financial Considerations Financial aspects of new proposals at ABI were con sidered from a number of perspectives, in part because relatively small, with 65 employees in the ratio of 1:5 salaried to hourly. The eight-month acquisition of the employees during the ramp-up is illustrated in Figure 3, with full employment occurring by March 2007. Financial Considerations Financial aspects of new proposals at ABI were con- sidered from a number of perspectives, in part because Plant manager Engineering/ Quality Manufacturing manager Personnel Engineer Shift 2 Supervisor Clerk Quality control Sift 3 supervisor Chers Cars Figure 1 Stanhope organization S246,000 124.000 22.000 of the interdependent nature of many proposals. The results of not investing in a proposal are normally com- pared with the results of investing and the differences noted. Variations on the investment assumptions are also tested, including errors in the forecast sales vol- umes, learning rates, productivities, selling prices, and cancellations of both current and future orders for exist- ing and potential business. For the Stanhope proposal, the site investment required is $3.012,000. The details of this investment are shown in Table 2. The total investment required amounts to $7,108,000 (plus required working capi- tal of $1,380,000). The equipment is depreciated over an eight-year life. ABI, under the revised tax laws, is in the Figure 1 Stanhope organization. 34 percent tax bracket. The price of the piston heads has been tenta- tively set at $25.45 apiece. ABI's expected costs are shown in Table 3. Table 2 Stanhope Site Capital Costs Land and Site Preparation land access roads/parking lot landscaping Building Costs building (67.000 sqf air conditioning power employee services legal fees and permits Auxiliary Equipment ABI company sign containers, racks, etc. flume coolant disposal furnishings forklift trucks Total 1,560,000 226,000 205,000 177.000 26,000 25.000 33.000 148.000 97.000 51.000 72.000 3,012.000 Some Concerns Jim had spoken with some of his colleagues about the FMS concept after the preliminary financial results had been tabulated. Their concerns were what now interested him. For example, he remembered one man ager asking: "Suppose Big Red's sales only reach 70 percent of our projections in the 2009-2010 time period, or say, perhaps as much as 150 percent; how would this affect the project? Does the FMS still apply or would you consider some other form of manufac turing equipment, possibly conventional or CNC with potential aftermarket application in the former case or a transfer machine in the latter case? 80 Total 60 Hourly 40 20 Salaried Aug Sept Oct 2006 Nov Dec Jan March Feb 2007 Figure 3 Stanhope labor buildup. 328 CHAPTER 7 / BUDGETING: ESTIMATING COSTS AND RISKS After-tax margins seem unreasonably high. Can we get such margins on a sole-source contract? Table 3 Piston Head Cost Summary Material 58,47 Labor 1.06 Variable overhead 2.23 Fixed overhead 2.44 Freight 0.31 Total Factory Cost 14.51 General & administrative 1.43 Scrap 0.82 Testing 0.39 Total Cost 17.15 Conclusion Jim had concerns about the project also. He wondered how realistic the demand forecasts were given the weak economy and what the Japanese might do. If the demand didn't materialire, ABI might be sorry they had invested in such an expensive piece of equipment as an FMS 328 CHAPTER 7 / BUDGETING: ESTIMATING COSTS AND RISKS After-tax margins seem unreasonably high. Can we get such margins on a sole-source contract? Table 3 Piston Head Cost Summary Material $8.47 Labor 1.06 Variable overhead 2.23 Fixed overhead 2.44 Freight 0.31 Total Factory Cost 14.51 General & administrative 1.43 Scrap 0.82 0.39 Total Cost 17.15 Testing Conclusion Jim had concerns about the project also. He wondered how realistic the demand forecasts were given the weak economy and what the Japanese might do. If the demand didn't materialize, ABI might be sorry they had invested in such an expensive piece of equipment as an FMS. Strategically, it seemed like ABI had to make this investment to protect its profitable position in the diesel engine business; but how far should this argu- ment be carried? Were they letting their past invest- ments color their judgment on new ones? He was also concerned about the memo questioning the high profit margins. They did seem high in the midst of a sluggish economy Another manager wrote down his thoughts as a memo to forward to Jim. He had two major concerns: . "Scenario Il" analysis assumes the loss of sub- stantial volume to competition. This seems rather unlikely QUESTIONS 1. How did ABI handle forecast risk? 2. Were ABI's Stanhope site costs in Table 2 derived by a top-down or bottom-up process? Why? 3. What are the answers to Steve White's questions? 4. What other factors are relevant to this issue? 5. How do the changes in assumptions mentioned by the other managers affect the proposal? 6. What position should Jim take? Why