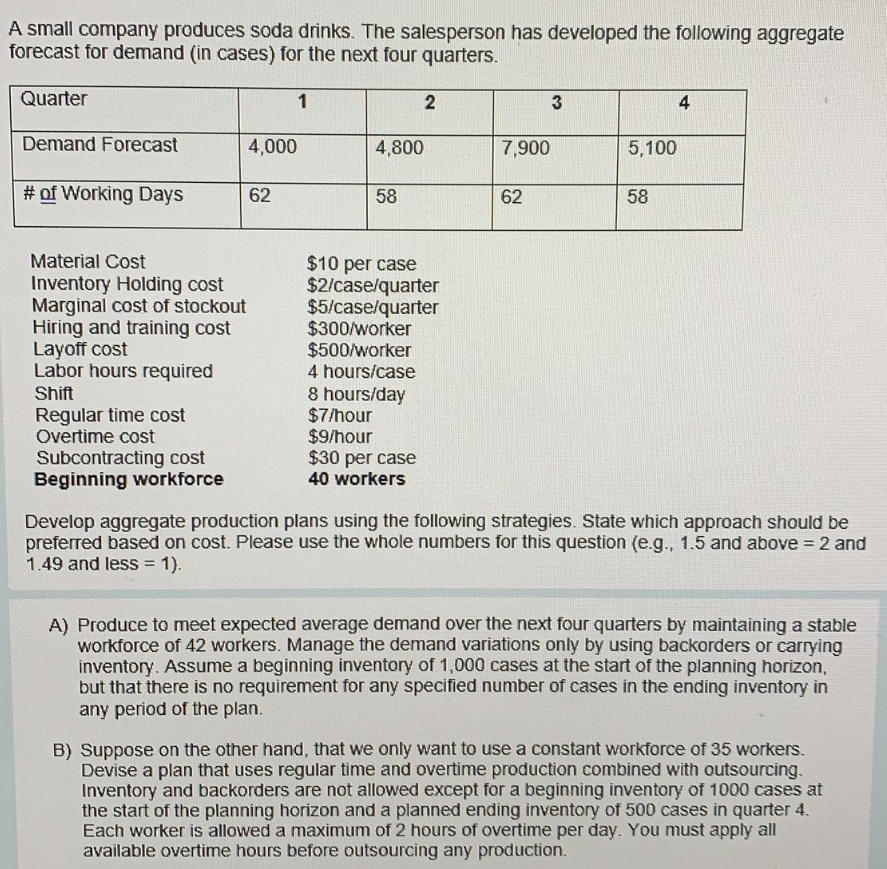

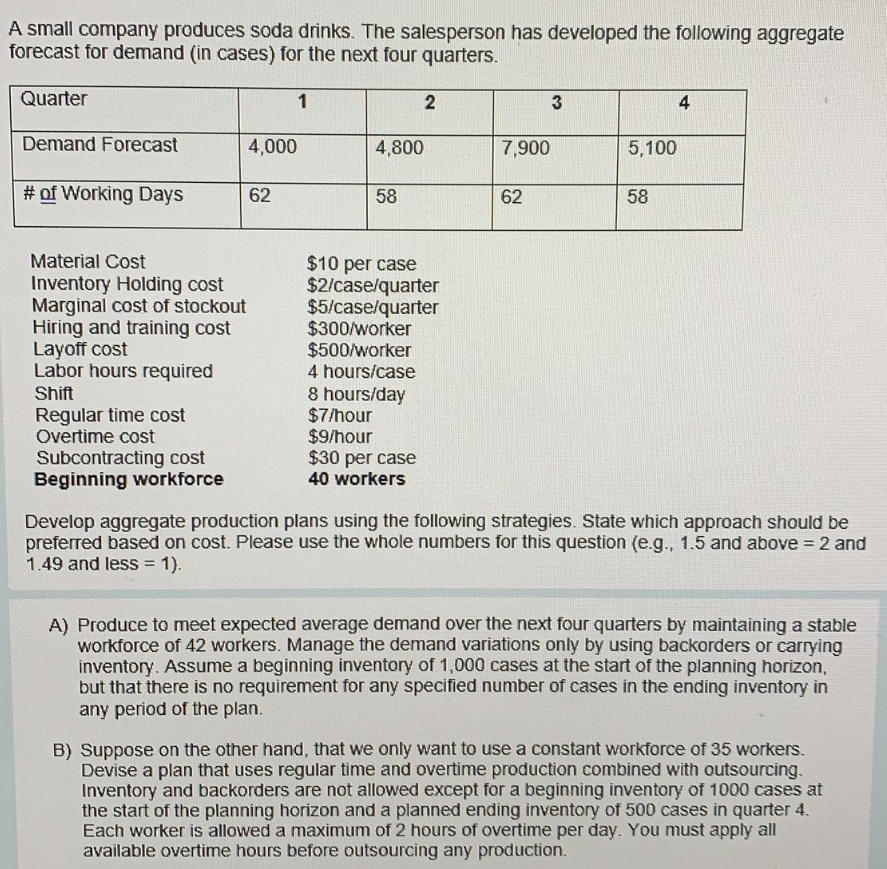

A small company produces soda drinks. The salesperson has developed the following aggregate forecast for demand (in cases) for the next four quarters. Quarter 1 2 3 4 Demand Forecast 4,000 4,800 7,900 5,100 # of Working Days 62 58 62 58 Material Cost Inventory Holding cost Marginal cost of stockout Hiring and training cost Layoff cost Labor hours required Shift Regular time cost Overtime cost Subcontracting cost Beginning workforce $10 per case $2/case/quarter $5/case/quarter $300/worker $500/ worker 4 hours/case 8 hours/day $7/hour $9/hour $30 per case 40 workers Develop aggregate production plans using the following strategies. State which approach should be preferred based on cost. Please use the whole numbers for this question (e.g., 1.5 and above = 2 and 1.49 and less = 1). A) Produce to meet expected average demand over the next four quarters by maintaining a stable workforce of 42 workers. Manage the demand variations only by using backorders or carrying inventory. Assume a beginning inventory of 1,000 cases at the start of the planning horizon, but that there is no requirement for any specified number of cases in the ending inventory in any period of the plan B) Suppose on the other hand, that we only want to use a constant workforce of 35 workers. Devise a plan that uses regular time and overtime production combined with outsourcing. Inventory and backorders are not allowed except for a beginning inventory of 1000 cases at the start of the planning horizon and a planned ending inventory of 500 cases in quarter 4. Each worker is allowed a maximum of 2 hours of overtime per day. You must apply all available overtime hours before outsourcing any production. A small company produces soda drinks. The salesperson has developed the following aggregate forecast for demand (in cases) for the next four quarters. Quarter 1 2 3 4 Demand Forecast 4,000 4,800 7,900 5,100 # of Working Days 62 58 62 58 Material Cost Inventory Holding cost Marginal cost of stockout Hiring and training cost Layoff cost Labor hours required Shift Regular time cost Overtime cost Subcontracting cost Beginning workforce $10 per case $2/case/quarter $5/case/quarter $300/worker $500/ worker 4 hours/case 8 hours/day $7/hour $9/hour $30 per case 40 workers Develop aggregate production plans using the following strategies. State which approach should be preferred based on cost. Please use the whole numbers for this question (e.g., 1.5 and above = 2 and 1.49 and less = 1). A) Produce to meet expected average demand over the next four quarters by maintaining a stable workforce of 42 workers. Manage the demand variations only by using backorders or carrying inventory. Assume a beginning inventory of 1,000 cases at the start of the planning horizon, but that there is no requirement for any specified number of cases in the ending inventory in any period of the plan B) Suppose on the other hand, that we only want to use a constant workforce of 35 workers. Devise a plan that uses regular time and overtime production combined with outsourcing. Inventory and backorders are not allowed except for a beginning inventory of 1000 cases at the start of the planning horizon and a planned ending inventory of 500 cases in quarter 4. Each worker is allowed a maximum of 2 hours of overtime per day. You must apply all available overtime hours before outsourcing any production