Answered step by step

Verified Expert Solution

Question

1 Approved Answer

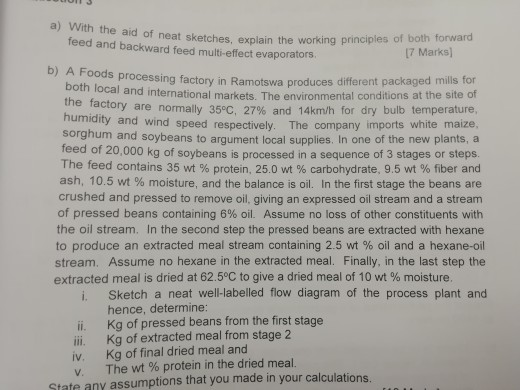

a) With the aid of neat sketches, explain the feed and backward feed multi-effect evaporators T heat sketches, explain the working principles of both forward

a) With the aid of neat sketches, explain the feed and backward feed multi-effect evaporators T heat sketches, explain the working principles of both forward [7 Marks) b) A Foods processing factory in Ramotswa s processing factory in Ramotswa produces different packaged mills for both local and international local and international markets. The environmental conditions at the site of factory are normally 35C, 27% and 14km/h for dry bulb temperature, numidity and wind speed respectively. The company imports white maize, sorghum and soybeans to argument local supplies. In one of the new plants, a teed of 20,000 kg of soybeans is processed in a sequence of 3 stages or steps. The feed contains 35 wt% protein, 25.0 wt% carbohydrate, 9.5 wt% fiber and ash, 10.5 wt% moisture, and the balance is oil. In the first stage the beans are crushed and pressed to remove oil, giving an expressed oil stream and a stream of pressed beans containing 6% oil. Assume no loss of other constituents with the oil stream. In the second step the pressed beans are extracted with hexane to produce an extracted meal stream containing 2.5 wt% oil and a hexane-oil stream. Assume no hexane in the extracted meal. Finally, in the last step the extracted meal is dried at 62.5C to give a dried meal of 10 wt% moisture. i Sketch a neat well-labelled flow diagram of the process plant and hence, determine: ii. kg of pressed beans from the first stage iii. Kg of extracted meal from stage 2 iv. kg of final dried meal and V. The wt% protein in the dried meal. State any assumptions that you made in your calculations. a) With the aid of neat sketches, explain the feed and backward feed multi-effect evaporators T heat sketches, explain the working principles of both forward [7 Marks) b) A Foods processing factory in Ramotswa s processing factory in Ramotswa produces different packaged mills for both local and international local and international markets. The environmental conditions at the site of factory are normally 35C, 27% and 14km/h for dry bulb temperature, numidity and wind speed respectively. The company imports white maize, sorghum and soybeans to argument local supplies. In one of the new plants, a teed of 20,000 kg of soybeans is processed in a sequence of 3 stages or steps. The feed contains 35 wt% protein, 25.0 wt% carbohydrate, 9.5 wt% fiber and ash, 10.5 wt% moisture, and the balance is oil. In the first stage the beans are crushed and pressed to remove oil, giving an expressed oil stream and a stream of pressed beans containing 6% oil. Assume no loss of other constituents with the oil stream. In the second step the pressed beans are extracted with hexane to produce an extracted meal stream containing 2.5 wt% oil and a hexane-oil stream. Assume no hexane in the extracted meal. Finally, in the last step the extracted meal is dried at 62.5C to give a dried meal of 10 wt% moisture. i Sketch a neat well-labelled flow diagram of the process plant and hence, determine: ii. kg of pressed beans from the first stage iii. Kg of extracted meal from stage 2 iv. kg of final dried meal and V. The wt% protein in the dried meal. State any assumptions that you made in your calculations

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started