Question

1.What is the Machining Cost per unit of fleece jacket using the activity-based costing system (system 3) in the fact pattern? Recall that under the

1.What is the Machining Cost per unit of fleece jacket using the activity-based costing system (system "3") in the fact pattern? Recall that under the activity based costing system, machining costs are allocated on the basis of machine hours. Please submit your answer as a number. For example $5.60/unit should be 5.60.

2.What is the total cost for Argo Nautical to produce a fleece jacket using the the activity-based costing system (system "3") in the fact pattern? Please submit your answer as a number. For example $5.60/unit should be 5.60

3.In a concise paragraph evaluate the profitability of golden fleece jackets. In this evaluation please reference the three costing systems, the target price (125% of cost) and the actual price.

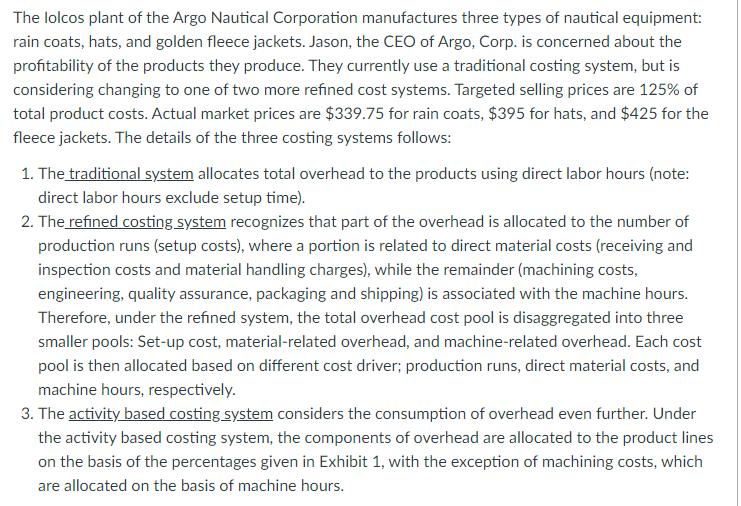

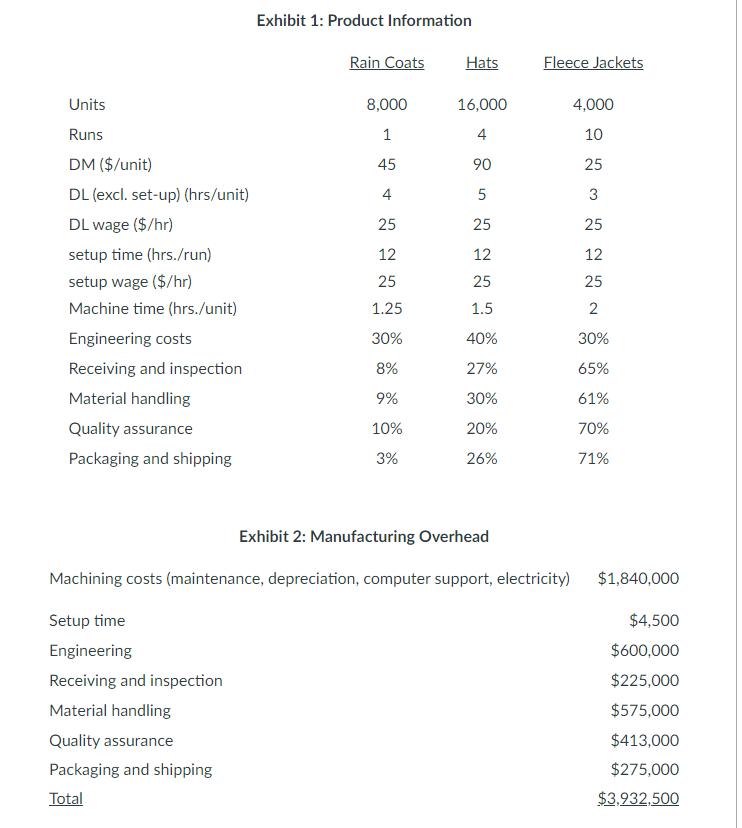

The lolcos plant of the Argo Nautical Corporation manufactures three types of nautical equipment: rain coats, hats, and golden fleece jackets. Jason, the CEO of Argo, Corp. is concerned about the profitability of the products they produce. They currently use a traditional costing system, but is considering changing to one of two more refined cost systems. Targeted selling prices are 125% of total product costs. Actual market prices are $339.75 for rain coats, $395 for hats, and $425 for the fleece jackets. The details of the three costing systems follows: 1. The traditional system allocates total overhead to the products using direct labor hours (note: direct labor hours exclude setup time). 2. The refined costing system recognizes that part of the overhead is allocated to the number of production runs (setup costs), where a portion is related to direct material costs (receiving and inspection costs and material handling charges), while the remainder (machining costs, engineering, quality assurance, packaging and shipping) is associated with the machine hours. Therefore, under the refined system, the total overhead cost pool is disaggregated into three smaller pools: Set-up cost, material-related overhead, and machine-related overhead. Each cost pool is then allocated based on different cost driver; production runs, direct material costs, and machine hours, respectively. 3. The activity based costing system considers the consumption of overhead even further. Under the activity based costing system, the components of overhead are allocated to the product lines on the basis of the percentages given in Exhibit 1, with the exception of machining costs, which are allocated on the basis of machine hours.

Step by Step Solution

3.42 Rating (161 Votes )

There are 3 Steps involved in it

Step: 1

1 Total Machine hours Description Amount Rain coat 8000 X 125 10000 Hats 16000 X 15 24000 Fleece jacket 4000 X 2 8000 Total Machine Hours 42000 mhr Machine Cost per mhr 184000042000 4381mhr So the tot...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started