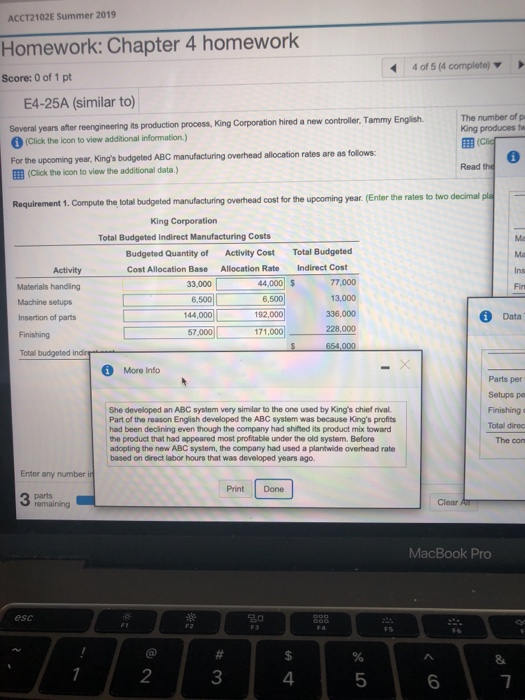

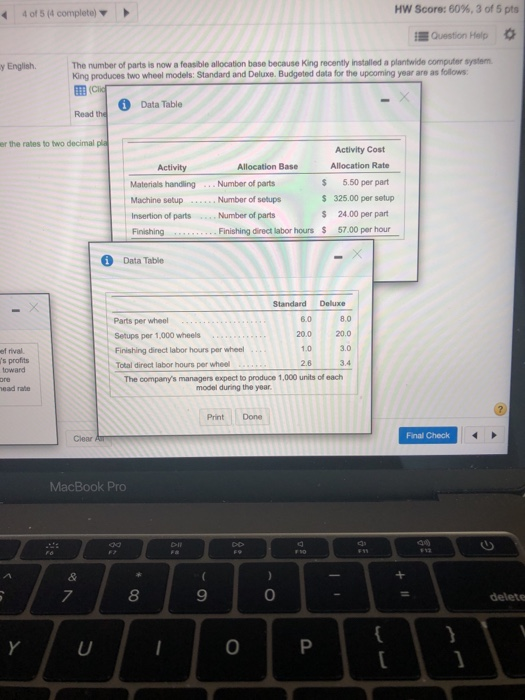

ACCT2102E Summer 2019 Homework:Chapter 4 homework 4 of 5 (4 complete) Score: 0 of 1 pt E4-25A (similar to) The number of p King produces tw Several years after reengineering its production process, King Corporation hired a new controller, Tammy English. i(Click the icon to view additional information.) (Clic For the upcoming year, King's budgeted ABC manufacturing overhead allocation rates are as follows: Read the E (Click the icon to view the additional data.) Requirement 1. Compute the total budgeted manufacturing overhead cost for the upooming year. (Enter the rates to two decimal pla King Corporation Total Budgeted Indirect Manufacturing Costs Ma Total Budgeted Activity Cost Budgeted Quantity of Ma Indirect Cost Allocation Rate Cost Allocation Base Activity Ins 44,000 $ 77,000 33,000 Materials handing Fin 6,500 13,000 6,500 Machine setups 192,000 336.000 Data 144,000 i Insertion of parts 228.000 171,000 57,000 Finishing 654,000 Total budgeted indirem More Info Parts per Setups pe She developed an ABC system very similar to the one used by King's chief rival. Part of the reason English developed the ABC system was because King's profits had been declining even though the company had shifted its product mix toward the product that had appeared most profitable under the old system. Before adopting the new ABC system, the company had used a plantwide overhead rate based on direct labor hours that was developed years ago. Finishing Total direc The com Enter any number in Print Done parts remaining Clear Ar MacBook Pro esc FI F3 F4 % & 2 3 4 5 6 eLO HW Score: 60% , 3 of 5 pts 4 of 5 (4 complete) EQuestion Help The number of parts is now a feasible allocation base because King recently installed a plantwide computer system King produces two wheel models: Standard and Deluxe. Budgeted data for the upcoming year are as follows y English (Clic Data Table Read the er the rates to two decimal pla Activity Cost Allocation Rate Allocation Base Activity ..Number of parts 5.50 per part Materials handling $ 325.00 per setup Machine setup Number of setups 24.00 per part Number of parts Insertion of parts $ 57.00 per hour Finis Finishing direct labor hours Data Table Deluxe Standard 6.0 8.0 Parts per wheel 20.0 20.0 Setups per 1.000 wheels 1.0 3.0 ef rival s profits Finishing direct labor hours per wheel Total direct labor hours per wheel 2.6 3.4 toward The company's managers expect to produce 1,000 units of each model during the year pre ead rate Print Done Final Check Clear Am MacBook Pro E12 E 10 FR 7 delete { P U Y +II