Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Activity-Based Product Costing Mello Manufacturing Company is a diversified manufacturer that manufactures three products (Alpha, Beta, and Omega) in a continuous production process. Senior management

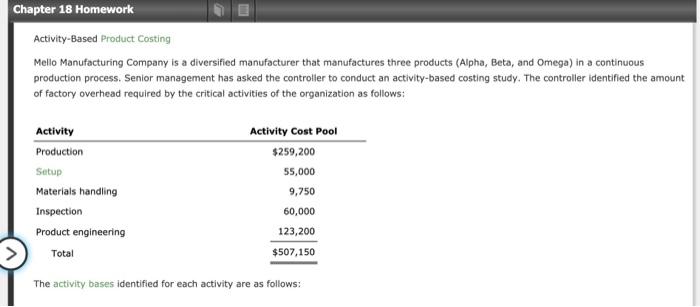

Activity-Based Product Costing

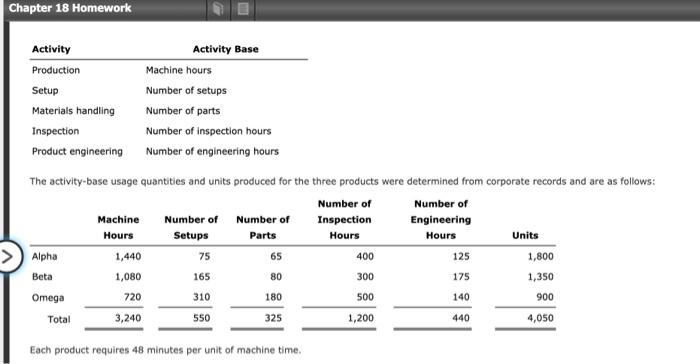

Mello Manufacturing Company is a diversified manufacturer that manufactures three products (Alpha, Beta, and Omega) in a continuous production process. Senior management has asked the controller to conduct an activity-based costing study. The controller identified the amount of factory overhead required by the critical activities of the organization as follows:

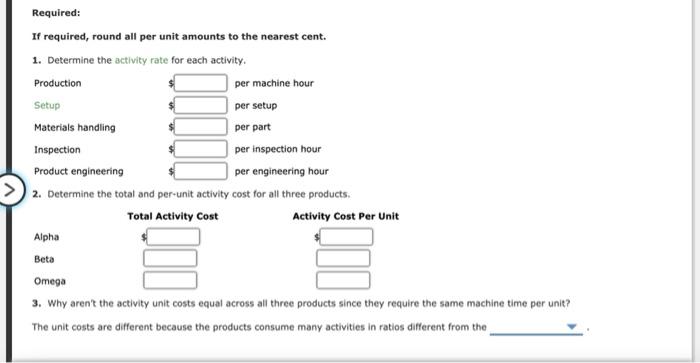

Required:

If required, round all per unit amounts to the nearest cent.

1. Determine the activity rate for each activity.

2. Determine the total and per-unit activity cost for all three products.

3. Why arent the activity unit costs equal across all three products since they require the same machine time per unit?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started