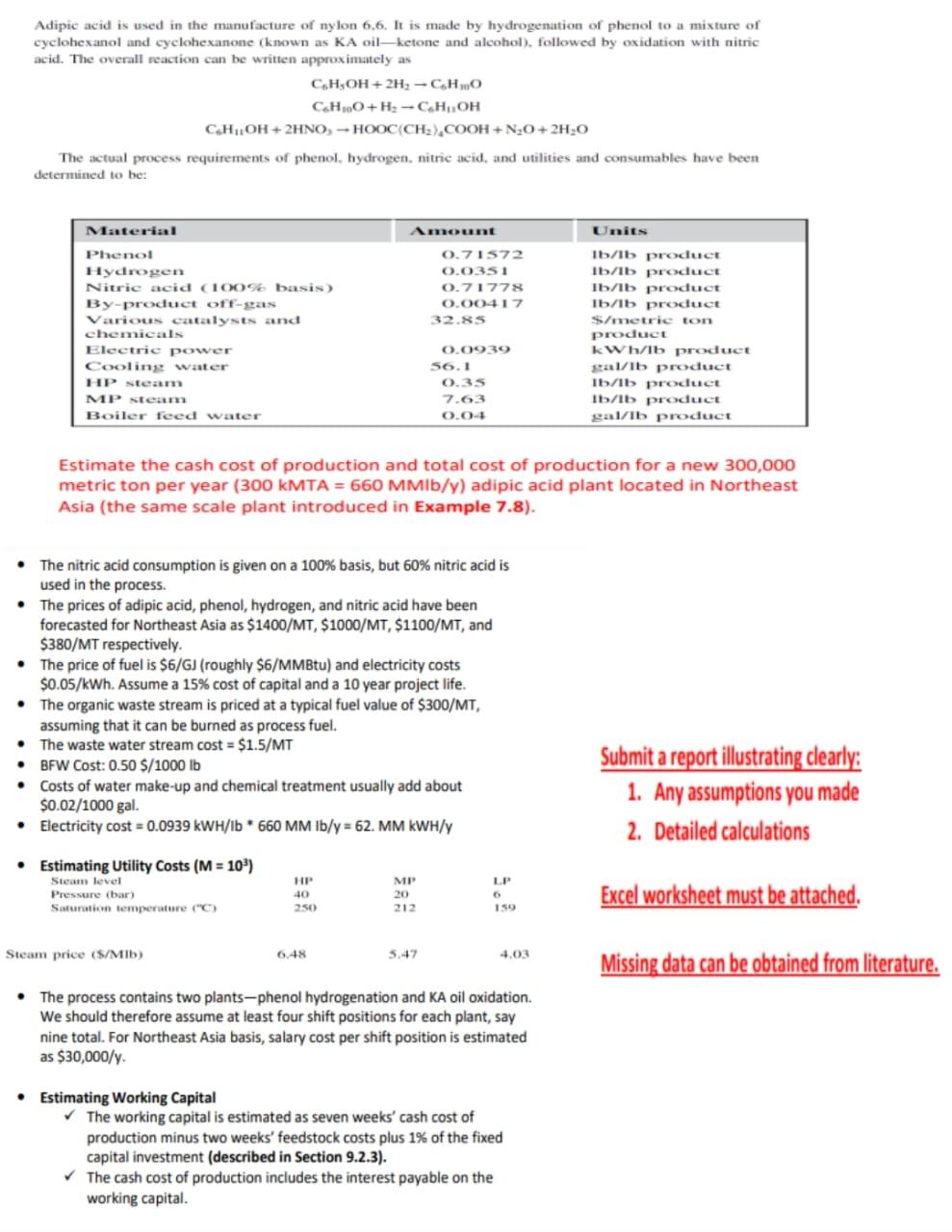

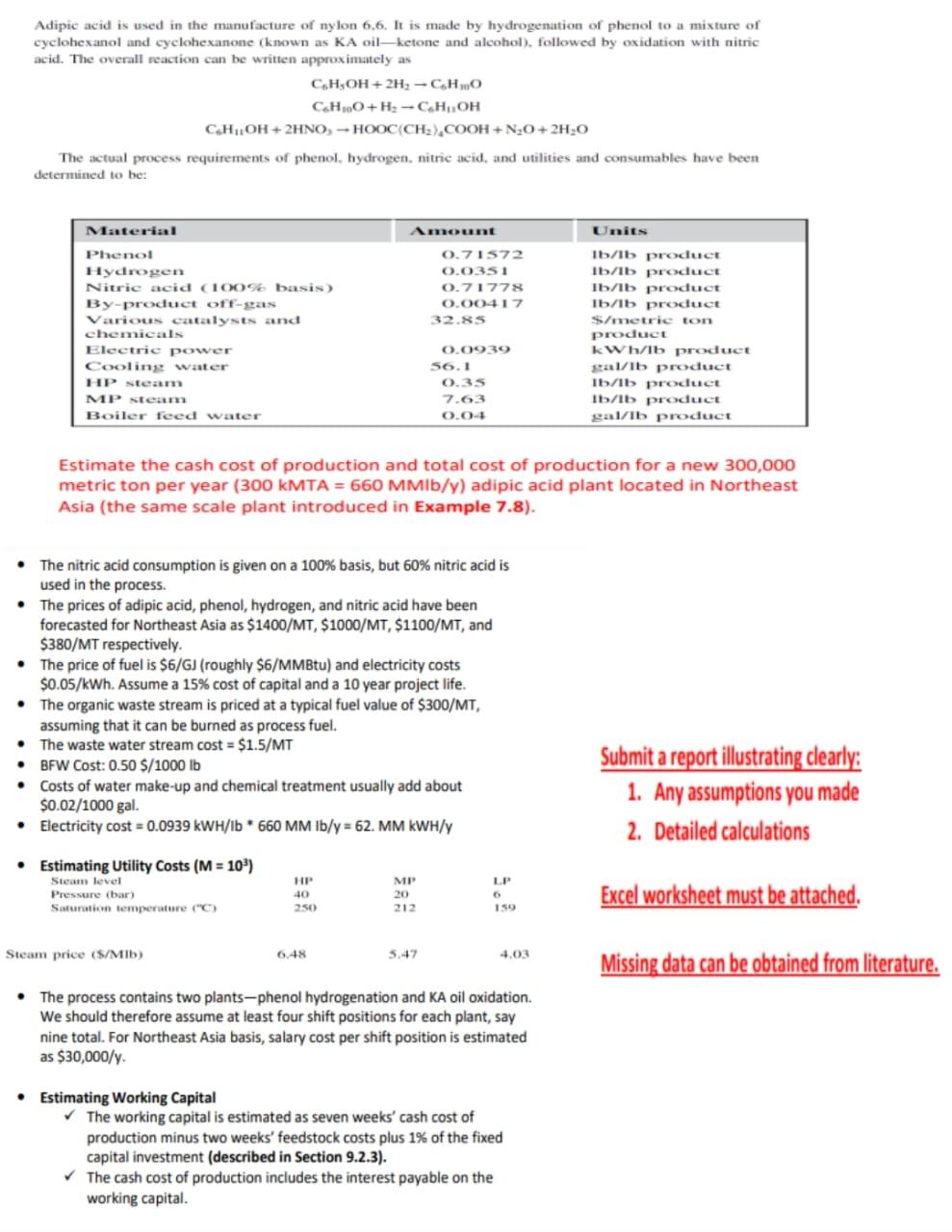

Adipic acid is used in the manufacture of nylon 6,6. It is made by hydrogenation of phenol to a mixture of cyclohexanol and cyclohexanone (known as KA oil-ketone and alcohol), followed by oxidation with nitric acid. The overall reaction can be written approximately as CH3OH +2H2=CHO C.H.O+H2 - CH OH C4H10H+ 2HNO - HOOC(CH3)COOH + NO + 2H20 The actual process requirements of phenol, hydrogen nitrie acid, and utilities and consumables have been determined to be: Material Phenol Hydrogen Nitric acid (100% basis) By-product off-gas Various catalysts and chemicals Electric power Cooling water HP steam MP Steam Boiler feed water Amount 0.71572 0.0351 0.71778 0.00417 32.85 Units 1b/lb product Ib/Ib product 1b/lb product Ib/lb product $/metrie ton product kWh/lb product gal/lb product Ib/lb product Ib/lb product gal/ib product 0.0939 56.1 0.35 7.63 0.04 Estimate the cash cost of production and total cost of production for a new 300,000 metric ton per year (300 KMTA = 660 MMb/y) adipic acid plant located in Northeast Asia (the same scale plant introduced in Example 7.8). The nitric acid consumption is given on a 100% basis, but 60% nitric acid is used in the process. The prices of adipic acid, phenol, hydrogen, and nitric acid have been forecasted for Northeast Asia as $1400/MT, $1000/MT, $1100/MT, and $380/MT respectively. The price of fuel is $6/G) (roughly $6/MMBtu) and electricity costs $0.05/kWh. Assume a 15% cost of capital and a 10 year project life. The organic waste stream is priced at a typical fuel value of $300/MT, assuming that it can be burned as process fuel. The waste water stream cost = $1.5/MT BFW Cost: 0.50 $/1000 lb Costs of water make-up and chemical treatment usually add about $0.02/1000 gal. Electricity cost = 0.0939 KWH/1b *660 MM ib/y = 62. MM KWH/y Submit a report illustrating clearly: 1. Any assumptions you made 2. Detailed calculations LP Estimating Utility Costs (M = 10%) Steam level Pressure (bar) Saturation temperature (C) HP 40 250 MP 20 212 Excel worksheet must be attached. ISO Steam price (S/Mb) 6.48 5.47 4.03 Missing data can be obtained from literature. The process contains two plants-phenol hydrogenation and KA oil oxidation We should therefore assume at least four shift positions for each plant, say nine total. For Northeast Asia basis, salary cost per shift position is estimated as $30,000/y. Estimating Working Capital The working capital is estimated as seven weeks' cash cost of production minus two weeks' feedstock costs plus 1% of the fixed capital investment (described in Section 9.2.3). The cash cost of production includes the interest payable on the working capital