Question

After reviewing the new activity-based costing system that Janis McGee has implemented at Joplin Industriess Port Arthur manufacturing facility, Kris Kristoff, the production supervisor, believes

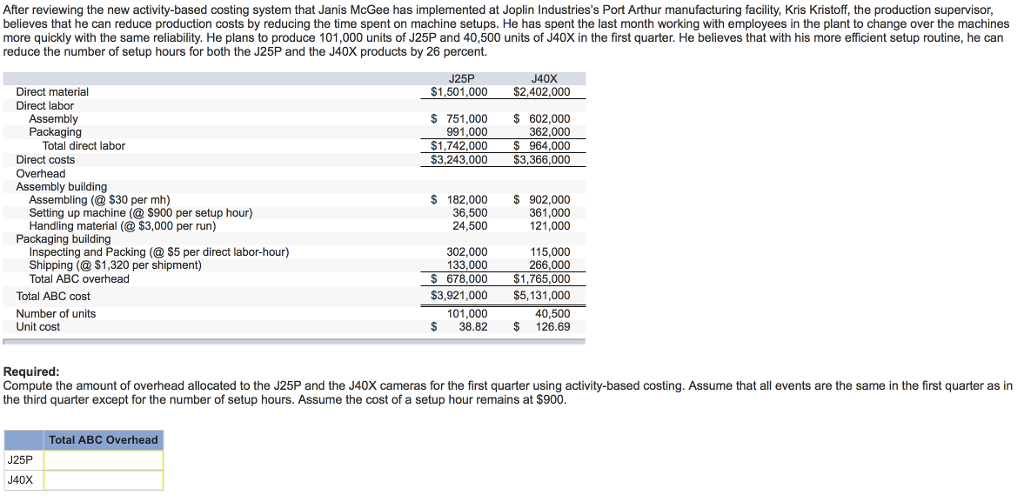

After reviewing the new activity-based costing system that Janis McGee has implemented at Joplin Industriess Port Arthur manufacturing facility, Kris Kristoff, the production supervisor, believes that he can reduce production costs by reducing the time spent on machine setups. He has spent the last month working with employees in the plant to change over the machines more quickly with the same reliability. He plans to produce 101,000 units of J25P and 40,500 units of J40X in the first quarter. He believes that with his more efficient setup routine, he can reduce the number of setup hours for both the J25P and the J40X products by 26 percent.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started