Aggregate Planning

i need help with this question please and thanks

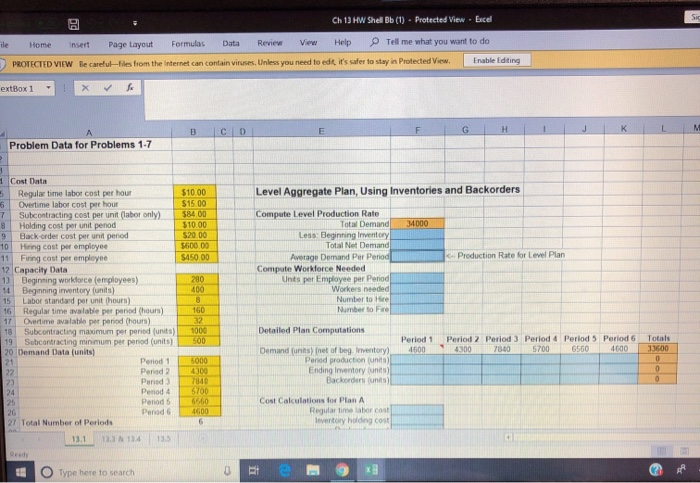

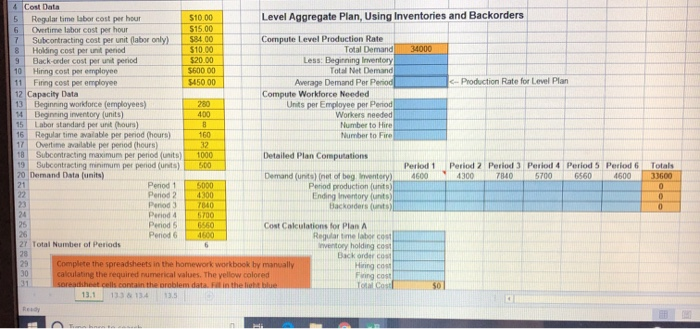

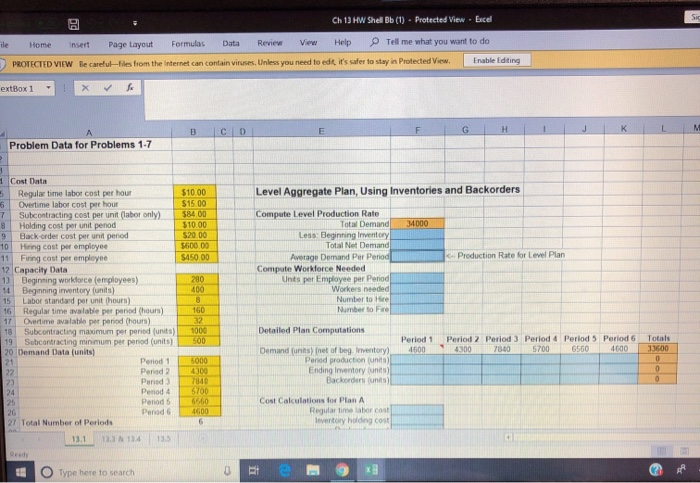

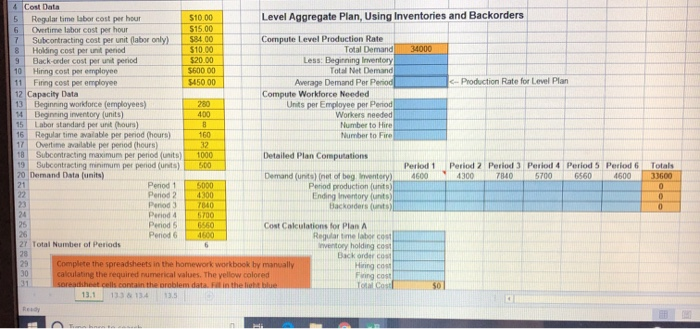

Ch 13 HW Shell Bb (1) Protected View - Excel Home Tent Page Layout Formulas Data Review View Help Tell me what you want to do PROTECTED VIEW Be careful-Files from the Internet can contain viruses. Unless you need to edit it's safer to stay in Protected View E rable Editing extBox1 - x fe C D HI Problem Data for Problems 1-7 Level Aggregate Plan, Using Inventories and Backorders $10.00 $15.00 $8400 $10.00 $12000 3600 DO $450 00 M000 CostData Regular time labor cost per hour Overtime labor cost per hour 7 Subcontracting cost per unit (labor only) bor only B Holding cost per unit period 9 Back-order cost per unit penod 10 Heng cost per employee 11 Firing cost per employee 12 Capacity Data 13 Beginning werdore employees) 10 Beginning i ntory units) 15 Labor standard per unit hours) 16 Regular time walabile per period (hours) 11 Overtime valabile per period hours) 18 Subcontracting maximum per period units) 19 Subcontracting minimum per period (units) 20 Demand Data (units) Period 1 Ponad 2 Pand) Peed Parads Pend 27 Total Number of Periode Compute Level Production Rate Total Demand Less Beginning inventory Total Net Demand Average Demand Per Period Compute Workforce Needed Units Employee per Penod Workers needed bert Numberto Production Rate for Level Plan 000 Detailed Plan Computations SOD Period 1 4600 Period 2 Period 4300 7800 Period 4 Period 5 Period 6 5700 6550 4600 Total 33600 ODO Demand funny net of beg Inventory) pand production units Ending Inventory units) - Backorders hunti)| 300 S700 Cost Calculations for Plan A - Regular time later cost lovertory holding cost Type here to search e 4 CostData 5 Regular time labor cost per hour $10.00 Level Aggregate Plan, Using Inventories and Backorders 6 Overtime labor cost per hour $15.00 7 Subcontracting cost per unit (labor only) Compute Level Production Rate 8 Holding cost per un period 10.00 Total Demand 9 Back-order cost per unit period $20.00 Less: Beginning Inventory 10 Hiring cost per employee $600 00 Total Net Demand 11 Firing cost per employee $450 00 Average Demand Per Period Production Rate for Level Plan 12 Capacity Data Compute Workforce Needed 13 Beginning workforce (employees) Units per Employee per Period 14 Beginning inventory (units) Workers needed 15 Labor standard per unit (hours) Numberto Hire 15 Regular time alable per period (hours) Number to Find 17 Overtime available per period (hours) 18 Subcontracting maximum per period (units) Detailed Plan Computations 19 Subcontracting minimum per period (unts) Period 1 Period 2 Period 3 Period 4 Period 5 Period 6 20 Demand Data (units) Demand (units) net of begwentory) 3100 TRID 5700 560 Period 1 5000 Period production (units) Period 2 4300 Ending Inventory (units) Period TO Hackorders (unts) Period 4 5700 Period 5 6560 Cost Calculations for Plan A Period 6 Regular time labor cos 27 Total Number of Periods Inventory holding cos Back onder con Complete the spreadsheets in the homework workbook by manually Hiring con calculating the required numerical values. The yellow colored Firing cost Soreaiheet cells contain the roblem data. Fill in the lichtbl 13.1 111134 35 1000 Totals