Answered step by step

Verified Expert Solution

Question

1 Approved Answer

All I need is Exhibit C please All I need help with is Exhibit C please Exhibit A (2016 Cost Data) Manufacturing costs for rattles

All I need is Exhibit C please

All I need help with is Exhibit C please

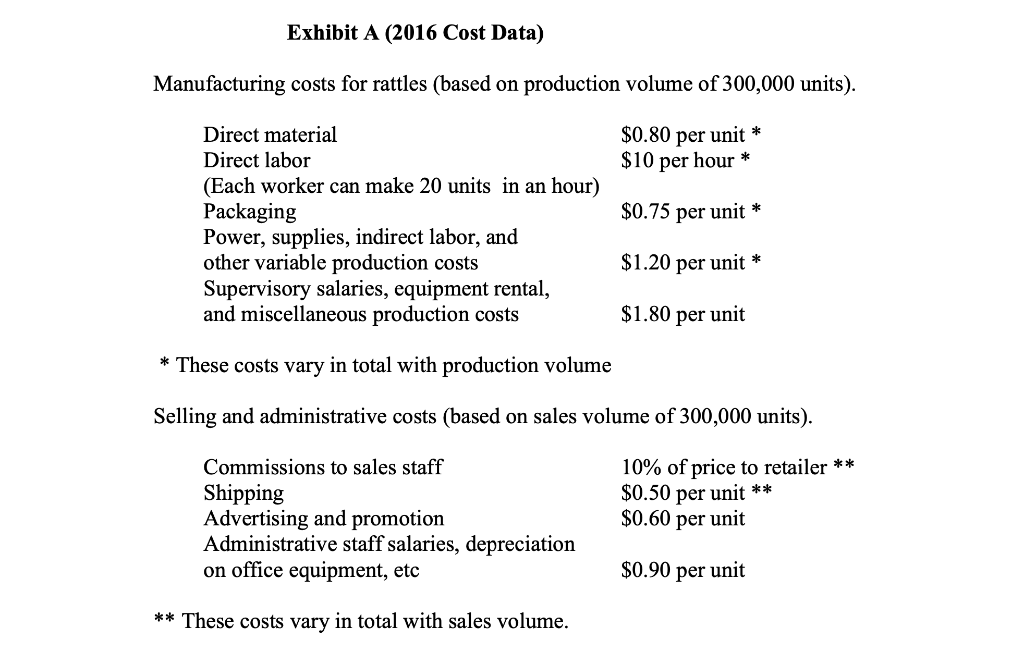

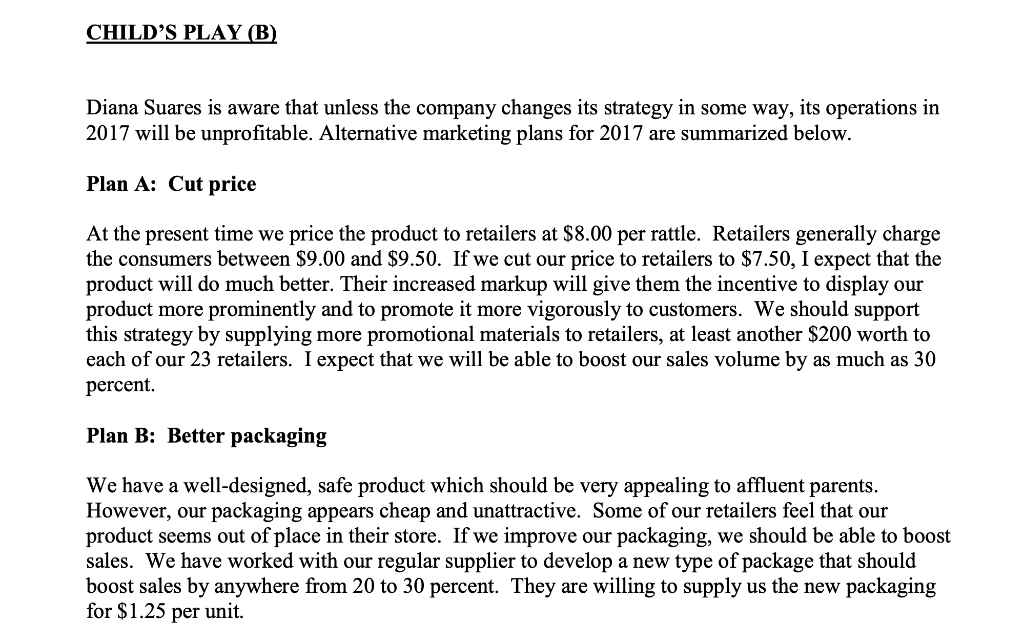

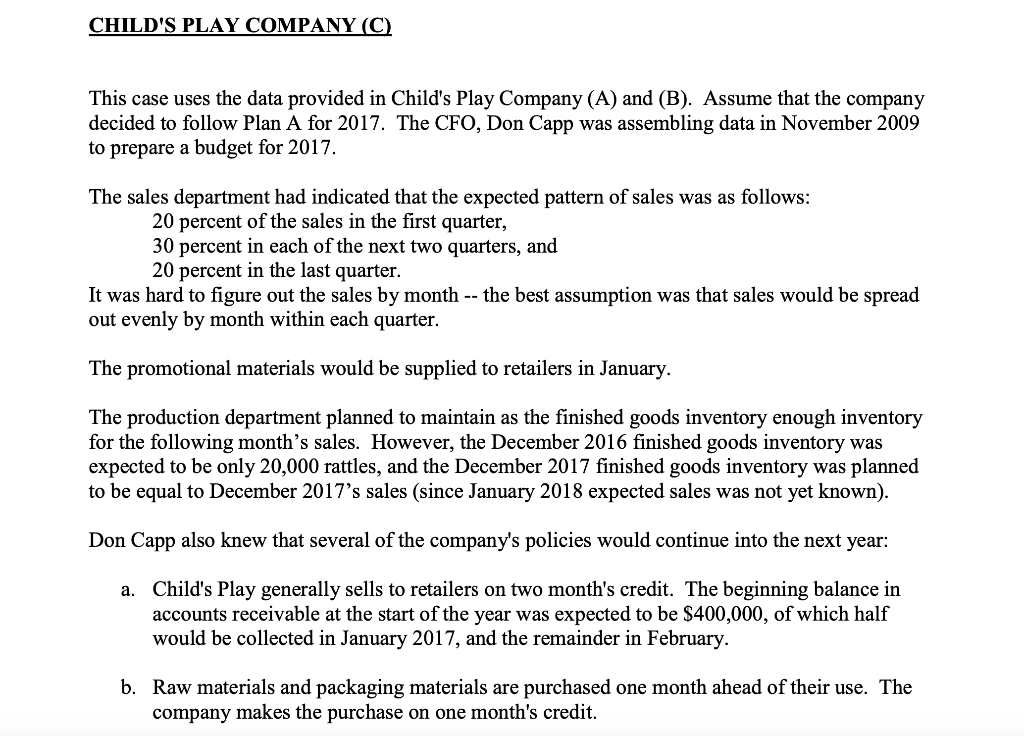

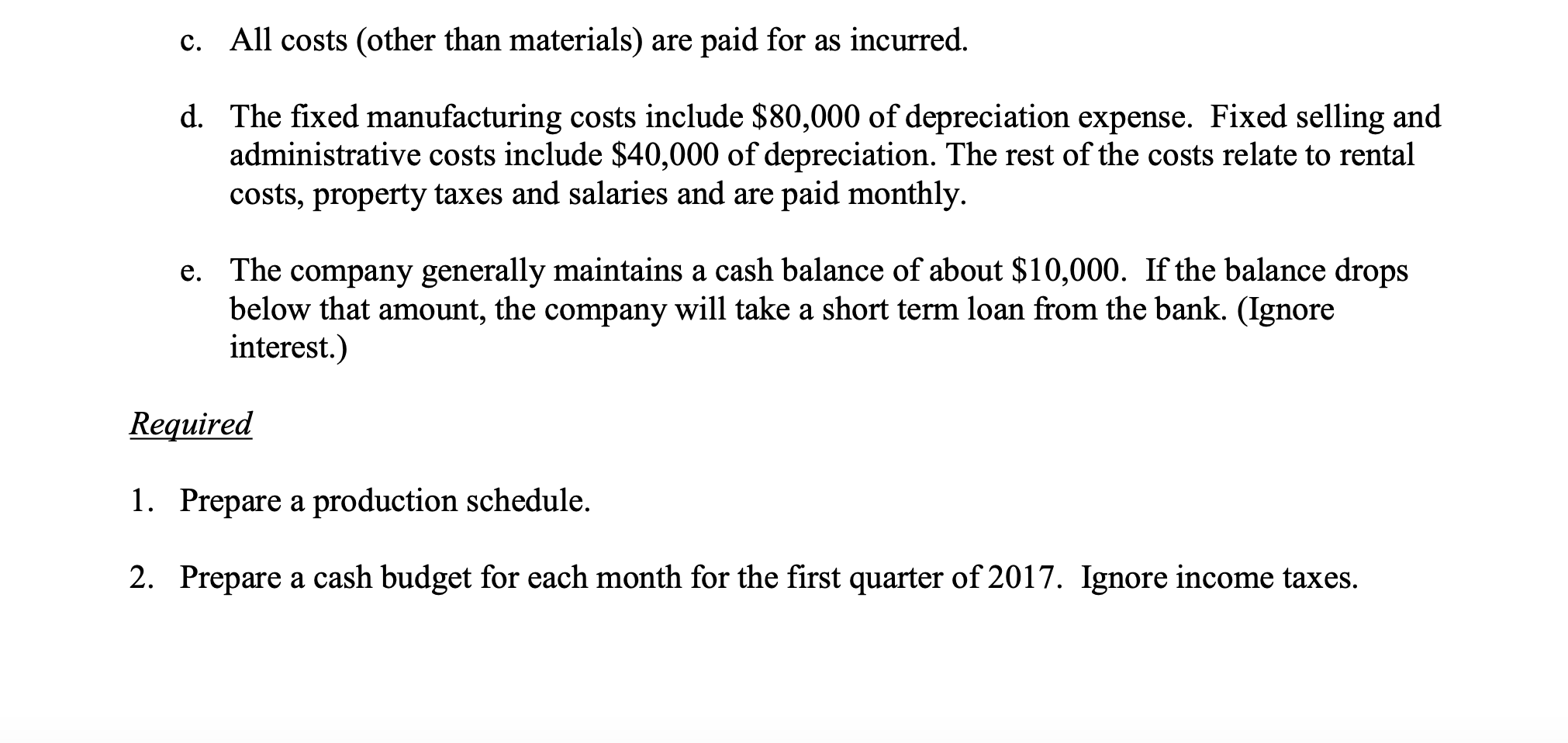

Exhibit A (2016 Cost Data) Manufacturing costs for rattles (based on production volume of 300,000 units). $0.80 per unit * $10 per hour * $0.75 per unit * Direct material Direct labor (Each worker can make 20 units in an hour) Packaging Power, supplies, indirect labor, and other variable production costs Supervisory salaries, equipment rental, and miscellaneous production costs $1.20 per unit * $1.80 per unit * These costs vary in total with production volume Selling and administrative costs (based on sales volume of 300,000 units). Commissions to sales staff Shipping Advertising and promotion Administrative staff salaries, depreciation on office equipment, etc 10% of price to retailer ** $0.50 per unit ** $0.60 per unit $0.90 per unit ** These costs vary in total with sales volume. CHILD'S PLAY (B) Diana Suares is aware that unless the company changes its strategy in some way, its operations in 2017 will be unprofitable. Alternative marketing plans for 2017 are summarized below. Plan A: Cut price At the present time we price the product to retailers at $8.00 per rattle. Retailers generally charge the consumers between $9.00 and $9.50. If we cut our price to retailers to $7.50, I expect that the product will do much better. Their increased markup will give them the incentive to display our product more prominently and to promote it more vigorously to customers. We should support this strategy by supplying more promotional materials to retailers, at least another $200 worth to each of our 23 retailers. I expect that we will be able to boost our sales volume by as much as 30 percent. Plan B: Better packaging We have a well-designed, safe product which should be very appealing to affluent parents. However, our packaging appears cheap and unattractive. Some of our retailers feel that our product seems out of place in their store. If we improve our packaging, we should be able to boost sales. We have worked with our regular supplier to develop a new type of package that should boost sales by anywhere from 20 to 30 percent. They are willing to supply us the new packaging for $1.25 per unit. CHILD'S PLAY COMPANY (C) This case uses the data provided in Child's Play Company (A) and (B). Assume that the company decided to follow Plan A for 2017. The CFO, Don Capp was assembling data in November 2009 to prepare a budget for 2017. The sales department had indicated that the expected pattern of sales was as follows: 20 percent of the sales in the first quarter, 30 percent in each of the next two quarters, and 20 percent in the last quarter. It was hard to figure out the sales by month -- the best assumption was that sales would be spread out evenly by month within each quarter. The promotional materials would be supplied to retailers in January. The production department planned to maintain as the finished goods inventory enough inventory for the following month's sales. However, the December 2016 finished goods inventory was expected to be only 20,000 rattles, and the December 2017 finished goods inventory was planned to be equal to December 2017's sales (since January 2018 expected sales was not yet known). Don Capp also knew that several of the company's policies would continue into the next year: a. Child's Play generally sells to retailers on two month's credit. The beginning balance in accounts receivable at the start of the year was expected to be $400,000, of which half would be collected in January 2017, and the remainder in February. b. Raw materials and packaging materials are purchased one month ahead of their use. The company makes the purchase on one month's credit. c. All costs (other than materials) are paid for as incurred. d. The fixed manufacturing costs include $80,000 of depreciation expense. Fixed selling and administrative costs include $40,000 of depreciation. The rest of the costs relate to rental costs, property taxes and salaries and are paid monthly. e. The company generally maintains a cash balance of about $10,000. If the balance drops below that amount, the company will take a short term loan from the bank. (Ignore interest.) Required 1. Prepare a production schedule. 2. Prepare a cash budget for each month for the first quarter of 2017. Ignore income taxes. Exhibit A (2016 Cost Data) Manufacturing costs for rattles (based on production volume of 300,000 units). $0.80 per unit * $10 per hour * $0.75 per unit * Direct material Direct labor (Each worker can make 20 units in an hour) Packaging Power, supplies, indirect labor, and other variable production costs Supervisory salaries, equipment rental, and miscellaneous production costs $1.20 per unit * $1.80 per unit * These costs vary in total with production volume Selling and administrative costs (based on sales volume of 300,000 units). Commissions to sales staff Shipping Advertising and promotion Administrative staff salaries, depreciation on office equipment, etc 10% of price to retailer ** $0.50 per unit ** $0.60 per unit $0.90 per unit ** These costs vary in total with sales volume. CHILD'S PLAY (B) Diana Suares is aware that unless the company changes its strategy in some way, its operations in 2017 will be unprofitable. Alternative marketing plans for 2017 are summarized below. Plan A: Cut price At the present time we price the product to retailers at $8.00 per rattle. Retailers generally charge the consumers between $9.00 and $9.50. If we cut our price to retailers to $7.50, I expect that the product will do much better. Their increased markup will give them the incentive to display our product more prominently and to promote it more vigorously to customers. We should support this strategy by supplying more promotional materials to retailers, at least another $200 worth to each of our 23 retailers. I expect that we will be able to boost our sales volume by as much as 30 percent. Plan B: Better packaging We have a well-designed, safe product which should be very appealing to affluent parents. However, our packaging appears cheap and unattractive. Some of our retailers feel that our product seems out of place in their store. If we improve our packaging, we should be able to boost sales. We have worked with our regular supplier to develop a new type of package that should boost sales by anywhere from 20 to 30 percent. They are willing to supply us the new packaging for $1.25 per unit. CHILD'S PLAY COMPANY (C) This case uses the data provided in Child's Play Company (A) and (B). Assume that the company decided to follow Plan A for 2017. The CFO, Don Capp was assembling data in November 2009 to prepare a budget for 2017. The sales department had indicated that the expected pattern of sales was as follows: 20 percent of the sales in the first quarter, 30 percent in each of the next two quarters, and 20 percent in the last quarter. It was hard to figure out the sales by month -- the best assumption was that sales would be spread out evenly by month within each quarter. The promotional materials would be supplied to retailers in January. The production department planned to maintain as the finished goods inventory enough inventory for the following month's sales. However, the December 2016 finished goods inventory was expected to be only 20,000 rattles, and the December 2017 finished goods inventory was planned to be equal to December 2017's sales (since January 2018 expected sales was not yet known). Don Capp also knew that several of the company's policies would continue into the next year: a. Child's Play generally sells to retailers on two month's credit. The beginning balance in accounts receivable at the start of the year was expected to be $400,000, of which half would be collected in January 2017, and the remainder in February. b. Raw materials and packaging materials are purchased one month ahead of their use. The company makes the purchase on one month's credit. c. All costs (other than materials) are paid for as incurred. d. The fixed manufacturing costs include $80,000 of depreciation expense. Fixed selling and administrative costs include $40,000 of depreciation. The rest of the costs relate to rental costs, property taxes and salaries and are paid monthly. e. The company generally maintains a cash balance of about $10,000. If the balance drops below that amount, the company will take a short term loan from the bank. (Ignore interest.) Required 1. Prepare a production schedule. 2. Prepare a cash budget for each month for the first quarter of 2017. Ignore income taxesStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started