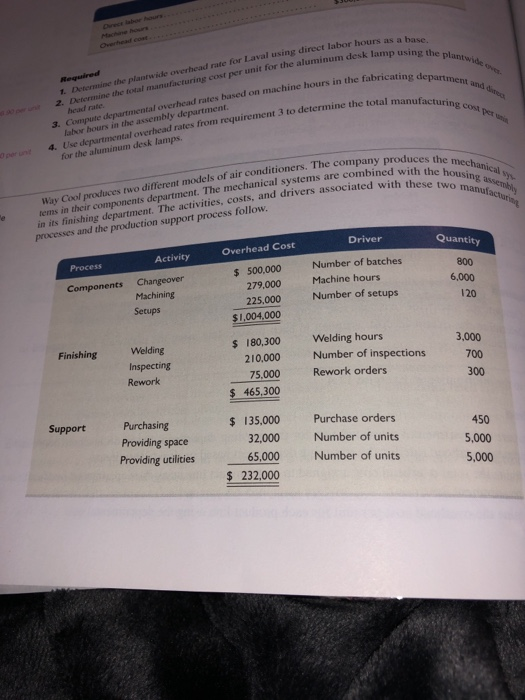

aluminum desk lamp using the Determine the total manufacturing cost per unit for the head rate plant in the fabricating department 1. Determine the plantwide overhead rate for Laval using direct labor hours as 2. 3. Compute departmental overhead rates based on machine hours 3 to determine the total manufact urin labor hours in the assembly department Per per unt4. Use departmental overhead rates from requiren for the aluminum desk lamps ferent models of air conditioners. The company produces the l Wa onents depart ment. The mechanical systems are combined with the houechanicl ool produces two diff and drivers associated with thesewsig in its finishing department. The activities, costs processes and the production support process folld two m isser manuf tems in their c Driver Quantity Activity Overhead Cost Process $ 500,000 Number of batches 800 6,000 120 Components Changeover 279,000Machine hours Machining Setups 225,000 Number of setups 1,004,000 Welding Inspecting Rework Welding hours Number of inspections Rework orders Finishing s 180,300 210,000 75,000 465,300 3,000 700 300 Support Purchasing Providing space Providing utilities $ 135,000 32,000 65,000 Purchase orders Number of units Number of units 450 5,000 5,000 $ 232.000 Model 145 is loss per unit for each model. Cand2 et price for Mo80fa and Comment on the results 5,000 DLH 500 MH 0,000 formation in Exercise 17.7 epthead assignment for the componemtie the ovethead co overhead assignment for the plantwide over- ment and direct g cost per unit Base your our ouchead costs to the depart bef phase orders. in the total cost per Deerm $250 for Model 145 and $180 for Mode nit shing department. Assign costs to the supper epu unit for each product line if the direct labor and direct materal c del 145 is $820 and the market pice fx Mold 2 s san. co n ove pecare $250 for Model 145 and $180ch product line 1212, the diet or model. Comment on the results. ofit or loss per unit for each model. Conm information in Exercise 17-7 to answer the follow to the hanical sys- g assembly ufacturing BC, compute the overhead cost per unit for each poduct Iine t Using total cost per unit for each product line if the direct labor and direct maderal. unit are $250 for Model 145 and $180 for Model 212. If the market price for Model 145 is $820 and the market price fo Model 212is profit or loss per unit for each model. Comment on the results tht 2. de m ck aw 17-10 Using ABC for strateg decisions Product A Product 0,000 units2,000 unts P1 P3 Consider the following data for two products of Gitano Manufacturing. Overhead Cost aluminum desk lamp using the Determine the total manufacturing cost per unit for the head rate plant in the fabricating department 1. Determine the plantwide overhead rate for Laval using direct labor hours as 2. 3. Compute departmental overhead rates based on machine hours 3 to determine the total manufact urin labor hours in the assembly department Per per unt4. Use departmental overhead rates from requiren for the aluminum desk lamps ferent models of air conditioners. The company produces the l Wa onents depart ment. The mechanical systems are combined with the houechanicl ool produces two diff and drivers associated with thesewsig in its finishing department. The activities, costs processes and the production support process folld two m isser manuf tems in their c Driver Quantity Activity Overhead Cost Process $ 500,000 Number of batches 800 6,000 120 Components Changeover 279,000Machine hours Machining Setups 225,000 Number of setups 1,004,000 Welding Inspecting Rework Welding hours Number of inspections Rework orders Finishing s 180,300 210,000 75,000 465,300 3,000 700 300 Support Purchasing Providing space Providing utilities $ 135,000 32,000 65,000 Purchase orders Number of units Number of units 450 5,000 5,000 $ 232.000 Model 145 is loss per unit for each model. Cand2 et price for Mo80fa and Comment on the results 5,000 DLH 500 MH 0,000 formation in Exercise 17.7 epthead assignment for the componemtie the ovethead co overhead assignment for the plantwide over- ment and direct g cost per unit Base your our ouchead costs to the depart bef phase orders. in the total cost per Deerm $250 for Model 145 and $180 for Mode nit shing department. Assign costs to the supper epu unit for each product line if the direct labor and direct materal c del 145 is $820 and the market pice fx Mold 2 s san. co n ove pecare $250 for Model 145 and $180ch product line 1212, the diet or model. Comment on the results. ofit or loss per unit for each model. Conm information in Exercise 17-7 to answer the follow to the hanical sys- g assembly ufacturing BC, compute the overhead cost per unit for each poduct Iine t Using total cost per unit for each product line if the direct labor and direct maderal. unit are $250 for Model 145 and $180 for Model 212. If the market price for Model 145 is $820 and the market price fo Model 212is profit or loss per unit for each model. Comment on the results tht 2. de m ck aw 17-10 Using ABC for strateg decisions Product A Product 0,000 units2,000 unts P1 P3 Consider the following data for two products of Gitano Manufacturing. Overhead Cost