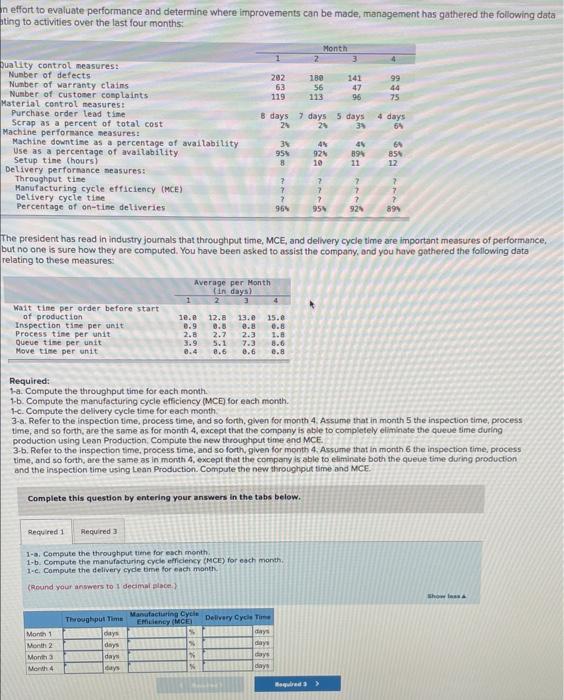

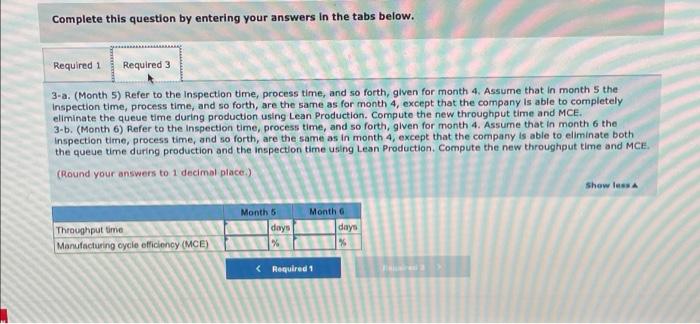

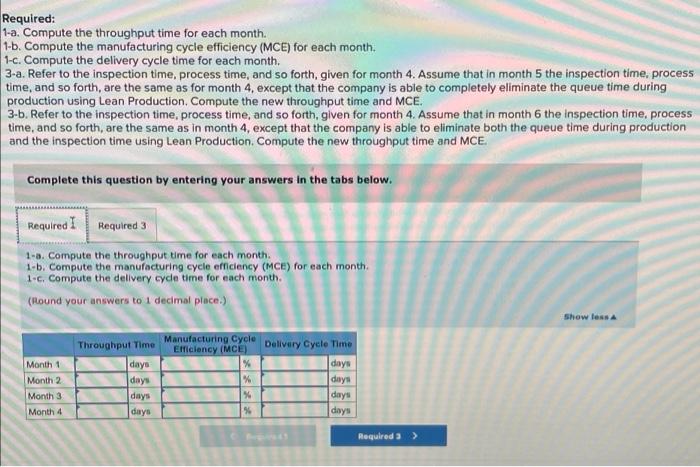

an effort to evaluate performance and determine where improvements can be made, management has gathered the following data anting to activities over the last four months Month 2 3 4 99 202 63 119 180 56 113 141 47 96 75 8 days 7 days 5 days 24 26 31 4 days 54 Duality control measures: Number of defects Number of warranty claims Number of customer complaints Material control measurest Purchase order lead time Scrap as a percent of total cost Machine performance measures: Machine downtime as a percentage of availability Use as a percentage of availability Setup time (hours) Delivery performance measures: Throughout time Manufacturing cycle efficiency (MCE) Delivery cycle tine Percentage of on-time deliveries 34 95$ 8 49 924 10 45 894 11 61 854 12 ? ? 7 2 7 7 95 2 2 ? 928 2 7 96 899 The president has read in industry Journals that throughput time, MCE, and delivery cycle time are important measures of performance, but no one is sure how they are computed. You have been asked to assist the company, and you have gathered the following data relating to these measures: Average per Month in days) 2 3 1 Wait time per order before start of production Inspection time per unit Process tine per unit Queue time per unit Move time per unit 15.0 0.8 10.0 8.9 2. 3.9 2.4 12.8 0.8 2.7 5.1 8.6 13.0 0.8 2.3 7.3 0.6 8.6 0.8 Required: 1-a. Compute the throughput time for each month. 1-b. Compute the manufacturing cycle efficiency (MCE) for each month. 1-c. Compute the delivery cycle time for each month 3-a. Refer to the inspection time, process time, and so forth, given for month 4. Assume that in month 5 the inspection time, process time, and so forth, are the same as for month 4, except that the company is able to completely eliminate the queue sime during production using Lean Production Compute the new throughout time and MCE. 3-b. Refer to the inspection time, process time, and so forth, given for month 4. Assume that in month 6 the inspection time, process time, and so forth, are the same as in month 4, except that the company is able to eliminate both the queue time during production and the inspection time using Lean Production. Compute the new throughout time and MCE Complete this question by entering your answers in the tabs below. Required 1 Required 1-a. Compute the throughput time for each month 1-b. Compute the manufacturing cycle efficiency (MCE) for each month 1.c. Compute the delivery cyde time for each month (Round your answers to 1 decimal place) Show less Manufacturing Cycle Emuency (MCE Delivery Cycle Time days Mon 1 Month 2 Month Month 4 Throughput Time days days days days daya Begirada > Complete this question by entering your answers in the tabs below. Required 1 Required 3 3-a. (Month 5) Refer to the Inspection time, process time, and so forth, given for month 4. Assume that in month 5 the Inspection time, process time, and so forth, are the same as for month 4, except that the company is able to completely eliminate the queue time during production using Lean Production. Compute the new throughput time and MCE. 3-b. (Month 6) Refer to the Inspection time, process time, and so forth, given for month 4. Assume that in month 6 the Inspection time, process time, and so forth, are the same as in month 4, except that the company is able to eliminate both the queue time during production and the Inspection time using Lean Production Compute the new throughput time and MCH. (Round your answers to 1 decimal place) Show Month 5 Month Throughput time days days Manufacturing cycle officiency (MCE) % >