Question

Analyze the case International Cosmetics Limited and answer the question given at the end (25 marks) International Cosmetics Limited Mr. Himendra Ratnayake, factory manager at

Analyze the case International Cosmetics Limited and answer the question given at the end

(25 marks)

International Cosmetics Limited

Mr. Himendra Ratnayake, factory manager at International Cosmetics Limited (ICL) in Ja-Ela near Colombo, Srilanka was concerned about the quantity & quality of output in the facility producing mosquito coils. The domestic sales for the mosquito coils had been growing steadily in the recent years & the company was forced to import coils from Malaysia to meet the demand. Of the company's annual sales for 35,000 cases, the plant could supply about 2000 cases a month. The balance was imported. The company was therefore considering alternatives to increase the capacity of the facility. He was also worried about the number of defective coils that were produced. Although they had taken several successful measures to reduce the number of defectives, he felt

there was a further scope for improvement.

Company background

ICL, a division of Maharaja Group, Srilanka, produced & marketed a variety of personal care products like shampoos, hair gels, & talcum powder. ICL also made mosquito coils & sold them under the Lion brand name in Srilanka. The major competition came from Mortein coils which held 80% of the market. Mortein coils enjoyed a very strong brand image & people sometimes referred to a mosquito coil as Mortein. ICL's Lion brand held most of the remaining marker share.

The factory had separate facilities for each product line. The mosquito coil facility had a total investment of Rs. 20 million Srilankan rupees, of which 15 million were spent on equipment. Last year, the total sales, including domestic production & imports were Rs. 87.5 million. Sales were seasonal & the period from January to March had low sales. Sales peaked during the monsoon which stretched from the third week of May to end of July & again in November and December. The facility employed a total of 44 regular workers & except for packaging line, it operated on a two shift basis throughout the year. The packing line was operated for only one shift per day. An additional 5 persons were employed for maintenance & supervision.

Each mosquito coil consisted of two spiral coils intertwined with each other and was called a double coil. Coils were sold in the retail market in packets of 5 double coils costing Rs 27.5 per packet for ICL's Lion brand. The competing brand, Mortein, sold at Rs. 30 per packet. ICL's margins from domestic production were 5 to 6 times the margin on sales from imported coils.

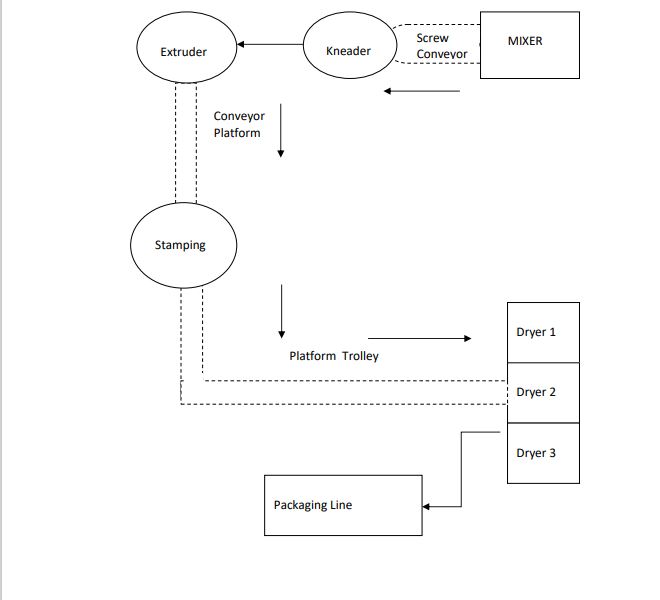

Production Process

The first step in the production process was dry mixing tabu powder, starch & wood dust. This mixing was done in a dry mixer which could process 50 kgs at a time in about 20 minutes. The mixer was located separately in a small room in a rear corner of the factory. After mixing, the mix was then sent to a kneader, located on the main shop floor along with other equipments required for the production of coils. About 32 kgs of water was added along with the active ingredient, Pynamine Forte & a colouring agent. Processing in the kneader took another 15 minutes. A visual & a sensory check were made on the quality of the output which was in the form of dough or a paste called wet mix. The production supervisor mentioned that it was difficult to fully standardise the output since some of the ingredients like wood dust varied from batch to batch. After kneading, the dough was crushed to remove any lumps & then passed through the extruder, which converted the dough into wide sheets which were about 4 mm thick & a metre wide. There was some rejection of material at this stage but that didn't exceed more 1% or 2% of the total weight. The extruder took 35 minutes to

process a batch of material from the kneader.

The output from the extruder was fed continuously into a stamping machine, where a set of 7 dies stamped out wet double coils each weighing 45 grams. These coils were loaded onto trays with each tray having two rows of 7 coils each. The stamping machine was designed to operate at 18 strokes a minute. However, to reduce the problem of defective coils, it was operated at 12 strokes per minute. The production supervisor mentioned that it took about 35 minutes including 10 minutes of setup to process one batch of material, yielding about 1800 double coils per batch. The stamping machine was used two shifts every day.

There were three operators at this machine. One helped to load trays, another to unload trays and a third to check quality, which was done visually. Any defective coils were removed from the tray. It had been observed that there were quite a few defective coils. For instance, it was noticed that the stamped coils sometime broke as they fell onto the trays used for storing the wet coils. They felt that if they could cushion the trays, then the number of broken or damaged coils would come down. After trying different materials like cardboard, paper and plastic, they finally decided to use x-ray film. The defect rates did come down as a result of this change.

They also considered using statistical process control methods to improve yield. However, it was difficult to standardize the process given the varying composition of raw materials some of which like wood dust were organic. There was also some variation in the composition of other raw materials. Finally based on the advice of a consultant, they decided to increase the thickness of the extruded sheets from 3.8 mm to 4 mm. This helped to reduce the problem of breaking or snapping of the wet sheets coming out of the extruder which fed into the stamping machine. However, it did increase the weight of the coil & the variable cost of production. The output of the stamping machine measured in number of coils per batch also came down since more material was used for each coil. Further, as mentioned earlier, operating the machine at 12 strokes a minute instead of 18 strokes a minute, increased the time it took to process a batch. All rejected material was recycled through the stamping machine after further extrusion.

After stamping, trays were loaded onto trolleys, each of which could accommodate 135 trays. Trolleys were wheeled into a dryer, which consisted of a long closed room or chamber which could be completely sealed off. The company had 70 trolleys & 3 dry chambers each of which could accommodate 28 trolleys. Hot dry air was circulated in the dryer at about 70 degree centigrade to dry the wet coils. The entire drying operation or firing took about 14 hours. During firing, the hot air circulation was switched off, and it took another 2 hours for the dryer to cool. It was then opened, the trolleys were wheeled out into a storage area earmarked for trolleys and the trays were unloaded from the trolleys. The unloading operation took another 30 minutes. During full scale production, one dryer was normally in operation i.e. either under firing or cooling, while a second was being loaded. All three drying chambers were rarely in use. (i.e. being loaded, fired or unloaded at the same time

After the trolleys were unloaded and the trays removed from the trolleys, the coils were manually removed from the trays & kept ready for packing. The trays were then available for use in the stamping machine. The dry double coils, which now weighed 27 gm each, were placed on a slowly moving line where workers visually inspected them, removing any defective coils. They were then stacked in lots of 5 each & passed into the packing machine which wrapped them in cellophane wrapping. Although the machine could operate at the speed of 70 packets a minute, it was actually operated at 50 packets a minute to match the speed of the line workers inspecting & loading coils. On the average, about 5% of the dry coils were rejected from the packing line. The wrapped lots of 5 coils were manually placed in cartons or packets, which in turn were placed in cardboard cases for

shipping. Each case contained 100 packets. Although coils were shipped in cases (of 100 packets each) they were sold at retail stores in packets.

As mentioned earlier, the average output of the plant was 2000 cases a month while operating in two shifts. Even though sales were seasonal production was steady. The plant manager felt that capacity was a bottleneck and demand far exceeded the production since about 11000 coils were being imported & sold under the Lion brand last year.

Purchasing & Costing

There are three major items that were purchased. Pynamine Forte, the active ingredient, was imported from Japan through the Sumitomo Corporation, which had a local representative in Colombo. Orders were placed once in 2 months since ICL had to place at least equal to a specified minimum order quantity. The other two major items, tabu powder & starch were imported from Malaysian distributor, who in turn obtained stocks from Indonesia. These were purchased once a month in lots of 12 tons & 3 tons for tabu powder & starch respectively. Receipt of orders had been regular & the company didn't face any difficulty with the present arrangement. However, raw materials were a major component of total cost & they were keen to explore ways of reducing costs.

Of the total cost of raw materials & packaging 65% was the cost of raw materials. Of the total raw material cost, about 40% was the cost of Pynamine forte & about 27% was the cost of the tabu powder. The margin on Sales was about 25%

Mr. Himendra's dilemma

Mr. Himendra was wondering if he could achieve higher output from the plant without additional investments in equipment & machinery. Specifically, he was thinking about the best way to use the drying chambers. Currently they are loaded in tray containing the wet stamped coils on the trolleys which were then wheeled into the drying chamber. However, some of the trays were not fully loaded as the defective coils obtained from stamping were taken out. Someone even suggested increasing the inventory of wet coils. Another option was of investing in new equipment to increase capacity which would require additional funds. If he chose this option he would have to decide the equipment to buy, & how much capacity to add. Another possibility was to increase the number of shifts.

Analyse the case and help Mr. Himendra arrive at a decision about the appropriate way to increase output from the plant and cut cost.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started