Answer the following question by reviewing the uploaded case study-

7. How does Polaris mitigate the risk that one of its suppliers fails to deliver a critical material in a timely or quality manner?

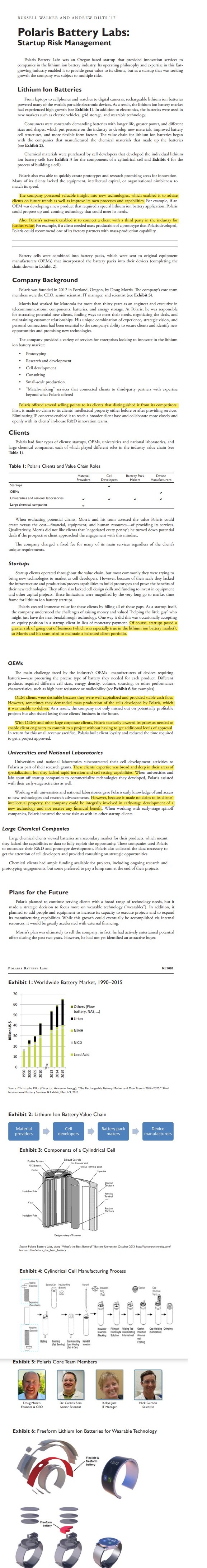

RUSSELL WALKER AND ANDREW DILTS -17 Polaris Battery Labs: Startup Risk Management Polaris Bartery Labs was an orcement.its advertise philosophy and expertise in this font- growing industry enabled it to provide great value to its clients, but as a startlap that was seeking Lithium Ion Batteries From laptops to cellphones and watches to digital cameras, rechargeable lithium ion batteries ad experienced high growth face Exhibit 1). In addition to electronics, the barseries were wound in ad edpremierdefrosted spiel the in addition to electronics, the batteri re constantly deman zes and shapes, which put pressure on the industry to develop new materials, improved battery with the companies that manufactured the chemical materials that made up the batteries a battery calls fore Exhibit's for the areamoments of a cylindrical ell and Exhibit & for the process of building a cell). Polaris also was able to quickly create prototypes and research promise Many of its clients lacked the equipment, intellectual capital, or organizational nimbleness to The company parched valuable insight into new technologies, which enabled it to advise could propose up-and coming technology that could meet its needs. the rise network enabled it to connect a client with a third party in the industry for I'd recommend one of its factory partners with man production capability. manufacturers (OEMs) that incorporated the battery packs leto their devices (completing the Company Background Polaris was founded in 2012 in Portland, Oregon, by Doug Morris. The Morris had worked for Motorola more than thirty years as an engineer and executive for attracting potential new clients, finding ways to meet their prods, negotiating the deals, and asonal connections had been essen company's ability to secure clients and identify new on battery markets my provided a variety of service for ent ate in the lithium . Cell development * Consulting "Match-making" services that connected clients to third-party partners with expertise beyond what Polaris offered inst. it made no claim to its clients intellectual property either before or after providing services. openly with its clients in house RaED andwonder dient b Clients large chemical companies, each of which played different roles in the industry value chain (see Table I: Polaris Clients and Value Chain Roles Providing Developers Makers Manufacturers vershoes and natioral laboratories When evaluating potential clients, Morris and his team assessed the value Polaris could Qualitatively, Morris did not like clients that " negotiated every penny"; he turned down potential proached the engagement of any the turned do The company charged a fixed fee for many of its main services regardless of the client's ique requirements. Startups Startup clients operated throughout the value chain, but most common weir new technologies. They often also lacked cell design skills and funding to inve frame for lithium ion battery startups puny understood the challenges of raising money and valued the house position in a startup client in lies of monetary payment. Of course OEMs stry's OEMs-m batteries- was procuring the precise type of battery they needed for each product. characteristics, such as high heat resistance of malleability (see Exhibit 6 for examples), production of razed and provide ction of the cells develop rojects but also risked losing those clients' business in the future. With OEMs and ochie a return for this small revenue sacrifice. Polaris built client loyalty and reduced the time required get a project approved. Universities and National Laboratories Universities and national laboratories subcontracted their cell development with their early stage activities is way. Working with universities and national laboratories give Polaris early knowledge of and access rally involved in early stage development of a be with partof When working with early-stage Large Chemical Companies Large chemical clients viewed batteries as a secondary market for their products, which means to outsource their RacD and prototype development. Polaris also collected the data necessary to intention of cell dev totyping engagements, but some preferred to pay a lump sum at the end of their projects. Plans for the Future Polaris planned to continue serving clients with a broad range of technology nerds, but it its manufacturing capabilities. While this growth could eventually be accomplished via internal resources, it would be greatly accelerated with external financing ffers during the past two years. However, he had not yet identified an attractive buyer. POLARIS BATTERY LABS Exhibit I: Worldwide Battery Market, 1990-2015 Exhibit 2: Lithium Ion Battery Value Chain providers developers Battery pack Device Exhibit 3: Components of a Cylindrical Cell Exhibit 4: Cylindrical Cell Manufacturing Process Exhibit 5: Polaris Core Team Members Founder & CED Exhibit 6: Freeform Lithium Ion Batteries for Wearable Technology