Answered step by step

Verified Expert Solution

Question

1 Approved Answer

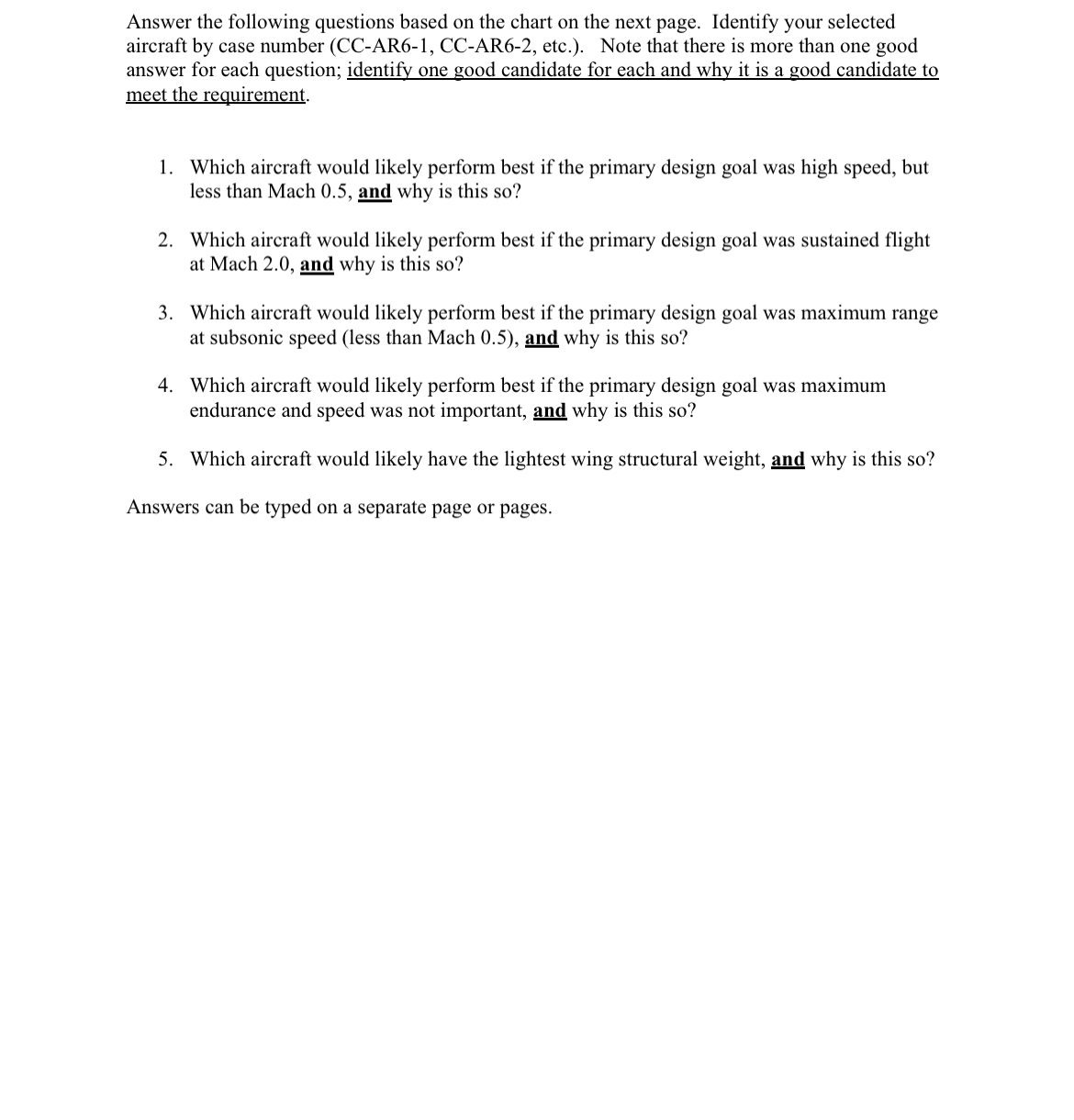

Answer the following questions based on the chart on the next page. Identify your selected aircraft by case number (CC-AR6-1, CC-AR6-2, etc.). Note that

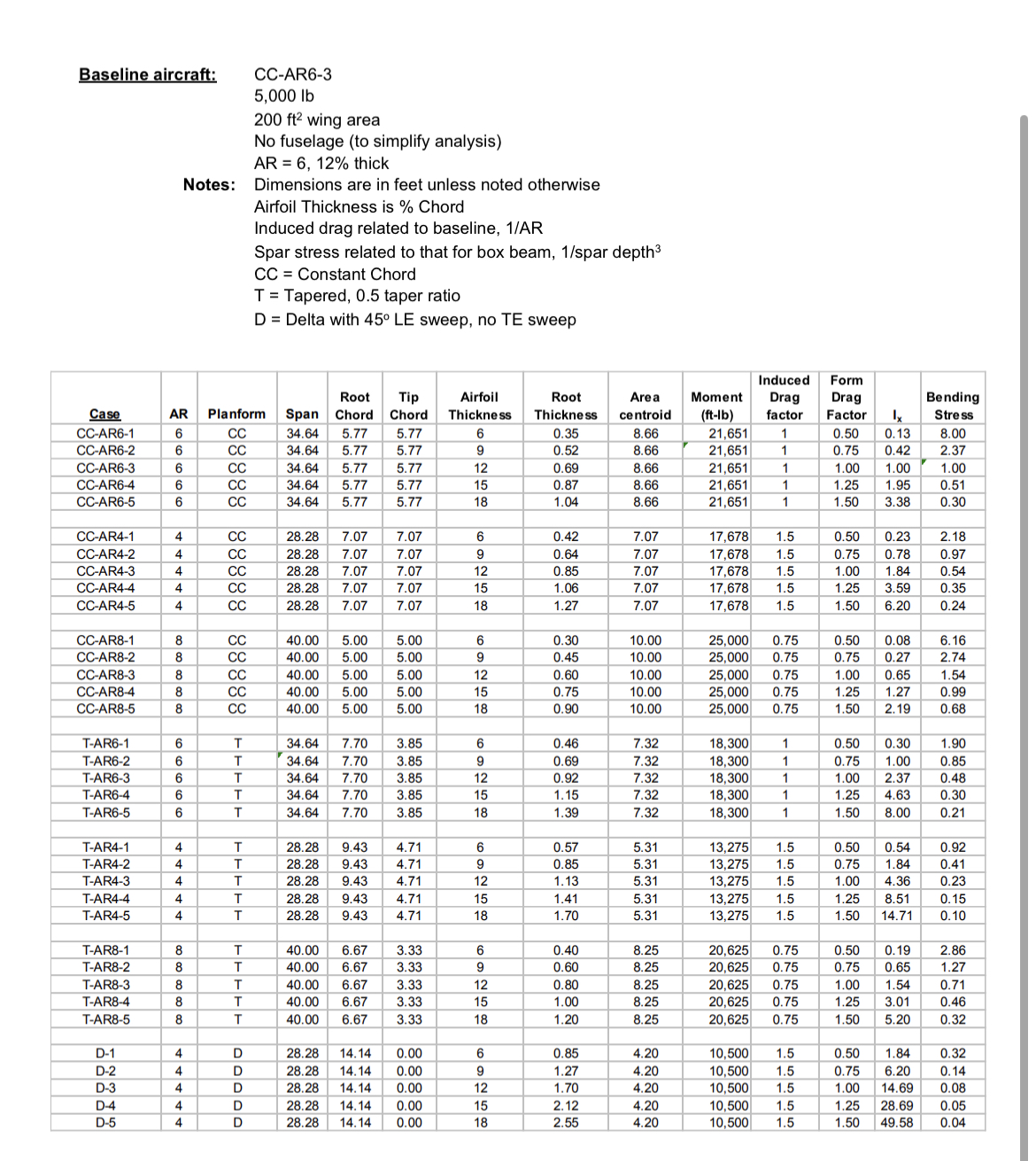

Answer the following questions based on the chart on the next page. Identify your selected aircraft by case number (CC-AR6-1, CC-AR6-2, etc.). Note that there is more than one good answer for each question; identify one good candidate for each and why it is a good candidate to meet the requirement. 1. Which aircraft would likely perform best if the primary design goal was high speed, but less than Mach 0.5, and why is this so? 2. Which aircraft would likely perform best if the primary design goal was sustained flight at Mach 2.0, and why is this so? 3. Which aircraft would likely perform best if the primary design goal was maximum range at subsonic speed (less than Mach 0.5), and why is this so? 4. Which aircraft would likely perform best if the primary design goal was maximum endurance and speed was not important, and why is this so? 5. Which aircraft would likely have the lightest wing structural weight, and why is this so? Answers can be typed on a separate page or pages. Baseline aircraft: Case CC-AR6-1 CC-AR6-2 CC-AR6-3 CC-AR6-4 CC-AR6-5 CC-AR4-1 CC-AR4-2 CC-AR4-3 CC-AR4-4 CC-AR4-5 CC-AR8-1 CC-AR8-2 CC-AR8-3 CC-AR8-4 CC-AR8-5 T-AR6-1 T-AR6-2 T-AR6-3 T-AR6-4 T-AR6-5 T-AR4-1 T-AR4-2 T-AR4-3 T-AR4-4 T-AR4-5 T-AR8-1 T-AR8-2 T-AR8-3 T-AR8-4 T-AR8-5 D-1 D-2 D-3 D-4 D-5 AR * Notes: 6 6 4 4 4 4 4 +4444 8 69696 TTTT 8 8 8 4 4 4 4 4 CC CC CC CC CC CC CC CC CC CC Planform Span CC 34.64 34.64 CC CC CC 34.64 34.64 CC 34.64 T T T T T T T T T T T CC-AR6-3 5,000 lb 200 ft wing area No fuselage (to simplify analysis) AR = 6, 12% thick Dimensions are in feet unless noted otherwise Airfoil Thickness is % Chord Induced drag related to baseline, 1/AR DDDDD Spar stress related to that for box beam, 1/spar depth CC Constant Chord T = Tapered, 0.5 taper ratio D = Delta with 45 LE sweep, no TE sweep Root Tip Chord Chord 28.28 28.28 28.28 28.28 28.28 w 28.28 7.07 7.07 28.28 7.07 7.07 7.07 7.07 28.28 7.07 7.07 28.28 28.28 7.07 7.07 40.00 5.00 40.00 5.00 40.00 40.00 40.00 28.28 28.28 28.28 5.77 5.77 28.28 28.28 34.64 7.70 34.64 7.70 34.64 7.70 34.64 7.70 34.64 7.70 5.77 5.77 5.77 4 5.00 5.00 5.00 40.00 6.67 40.00 40.00 40.00 40.00 6.67 9.43 9.43 9.43 9.43 9.43 14.14 14.14 14.14 5.77 5.77 14.14 14.14 5.77 5.77 5.77 3.33 6.67 3.33 6.67 3.33 6.67 3.33 3.33 5.00 5.00 5.00 5.00 5.00 3.85 3.85 3.85 3.85 3.85 4.71 4.71 4.71 4.71 4.71 0.00 0.00 0.00 0.00 0.00 Airfoil Thickness 6 9 12 15 18 6 9 12 15 18 6 9 12 15 18 6 9 12 15 18 6 9 12 15 18 6 9 12 15 18 6 9 12 15 18 Root Thickness 0.35 0.52 0.69 0.87 1.04 0.42 0.64 0.85 1.06 1.27 0.30 0.45 0.60 0.75 0.90 0.46 0.69 0.92 1.15 1.39 0.57 0.85 1.13 1.41 1.70 0.40 0.60 0.80 1.00 1.20 0.85 1.27 1.70 2.12 2.55 Area centroid 8.66 8.66 8.66 8.66 8.66 7.07 7.07 7.07 7.07 7.07 10.00 10.00 10.00 10.00 10.00 7.32 7.32 7.32 7.32 7.32 5.31 5.31 5.31 5.31 5.31 8.25 8.25 8.25 8.25 8.25 4.20 4.20 4.20 4.20 4.20 Induced Moment Drag (ft-lb) 21,651 21,651 21,651 21,651 21,651 Form Drag Bending factor Factor Ix Stress 1 1 18,300 18,300 18,300 18,300 18,300 1 1 1 17,678 1.5 17,678 1.5 17,678 1.5 17,678 1.5 17,678 1.5 25,000 0.75 25,000 0.75 25,000 0.75 25,000 0.75 25,000 0.75 1 1 1 1 1 13,275 1.5 13,275 1.5 13,275 1.5 13,275 1.5 13,275 1.5 20,625 20,625 0.75 0.75 20,625 0.75 20,625 0.75 20,625 0.75 10,500 1.5 10,500 1.5 10,500 1.5 10,500 1.5 10,500 1.5 0.50 0.75 1.00 1.25 1.50 0.50 0.75 1.00 1.25 1.50 0.50 0.75 1.00 1.25 1.50 0.50 0.75 1.00 1.25 1.50 0.50 0.30 0.75 1.00 1.00 2.37 1.25 4.63 1.50 8.00 0.54 0.50 0.75 1.00 1.25 1.50 14.71 1.84 4.36 8.51 0.13 8.00 0.42 2.37 1.00 1.00 1.95 0.51 3.38 0.30 0.23 2.18 0.97 0.54 0.78 1.84 3.59 0.35 6.20 0.24 0.50 0.19 0.75 H||| 0.08 6.16 0.27 2.74 0.65 1.54 1.27 0.99 2.19 0.68 .... 1.00 1.54 1.25 3.01 1.50 5.20 2.86 0.65 1.27 1.90 0.85 0.48 0.30 0.21 0.92 0.41 0.23 0.15 0.10 0.71 0.46 0.32 1.84 6.20 14.69 28.69 0.05 49.58 0.04 0.32 0.14 0.08

Step by Step Solution

There are 3 Steps involved in it

Step: 1

1 The aircraft that would likely perform best if the primary design goal was high speed but less tha...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started