any one of these

question number 1

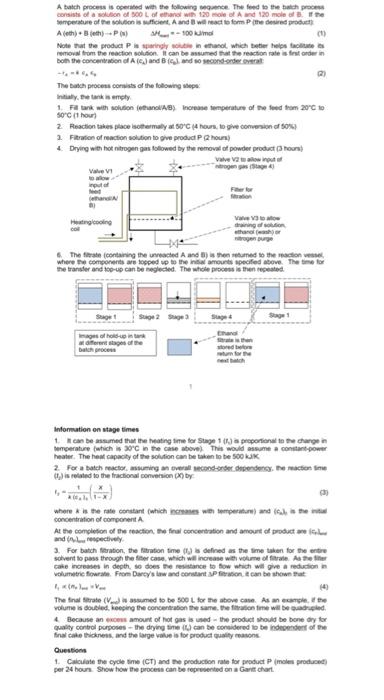

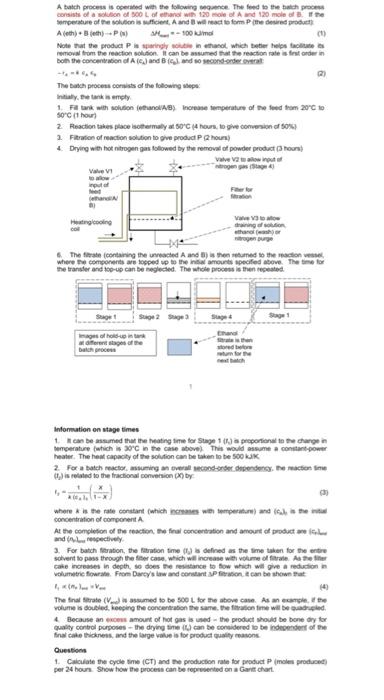

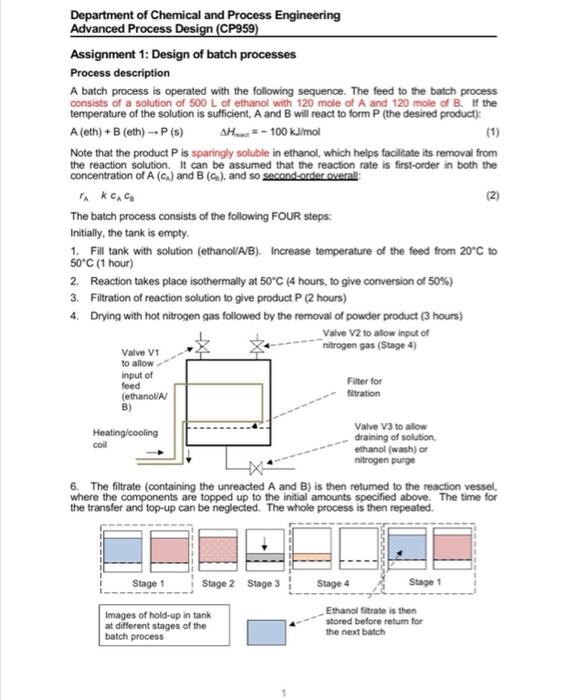

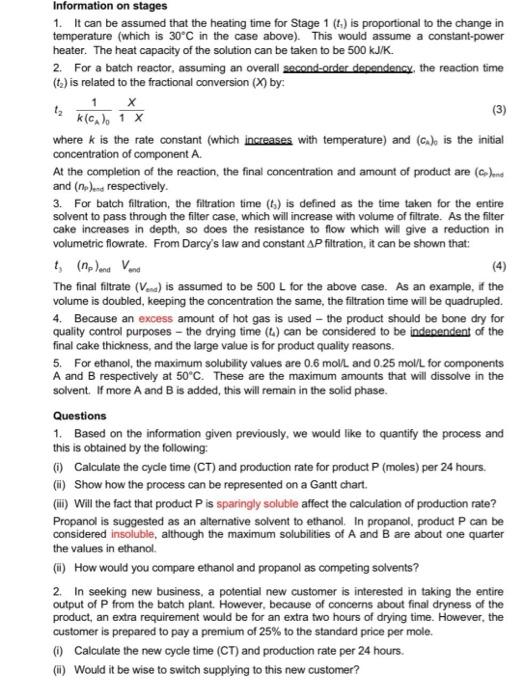

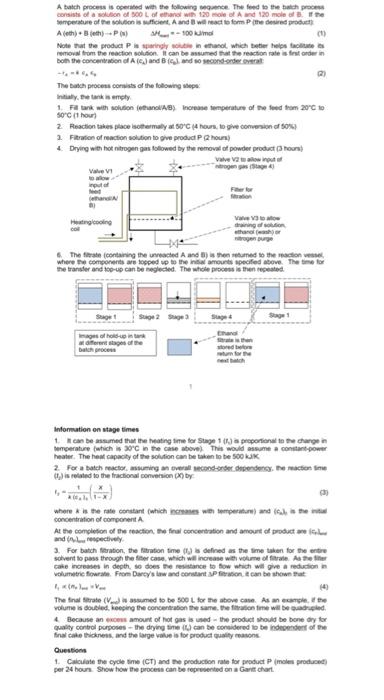

A batch process is operated with the following the food to the ticho consists of a solution of 300L of ethanol i 120 mole of A 120 mole of the amperature of the solution is sufficient and I will react to form the desired rodu Aleth BPN) 100ml Note that the produa Pering in that which there to removal from the reaction solution. It can be assumed that the reaction rate is fordern both the concentration of Aland Bland secondiderat The batch process con of the following we y reaks my 1. Fa tank with solution tha) se temperature of the feed from 2000 sochou 2 Reaction takes place of may at 30C 4 hours to greconversion of Son 2. Filtration of reaction solution to give product Phours Drying will hot nitrogen gas followed by the removal of powder productors Valve own Value VI agenta F al going Valto ng loon haror roger The rate containing the unreached A and B) is the tumed to the actions where the components are sopped up to the mounts specified above. The time for the transfer and top up can be neglected. The whole process is the reported. S2 Sage Sa Images of his were ofte Dalche than Streho more Information on age limes 1 can be assumed that the heating time for Stage 10 a proportional to the change in temperature which 30C in the case ove) This would me a constant power heater. The heat capacity of the solution can be taken to be 500 KJK 2. For a batch actor sunting overlederen, the action time is related to the fractional conversion by where that the rate constant (which normes with operature) and on the concentration of component At the completion of the reaction, the final concentration and amount of product and respectively 3. For batch fitration, the ration time defined as the time taken for the entire solvent to pass through the file cases, which will increase with volume offitate. As the cake increases in depth, so does the resistance to tow which will give a reduction volumetric flowrate From Darcy's low and constant stration can be shown at 44 The final rate asumed to be 500 L for the above ce. As a complete volumes doubled. Keeping the concentration the same, the freation time will be regled 4. Because an excoms amount of hot gas is used the product should be bone dy for quality control purposes-the dying time (1) can be considered to be independent of the final cake thickness and the large value is for product quality reasons Questions 1. Calculate the cycle time (CT) and the production rate for product Poles produced per 24 hours Show how the process can be represented on a Garis chart 1 Department of Chemical and Process Engineering Advanced Process Design (CP959) Assignment 1: Design of batch processes Process description A batch process is operated with the following sequence. The feed to the batch process consists of a solution of 500 L of ethanol with 120 mole of A and 120 mole of B. If the temperature of the solution is sufficient, A and B will react to form P (the desired product) A (eth) + B (eth) --P(s) AH...=-100 kJ/mol (1) Note that the product Pis sparingly soluble in ethanol, which helps facilitate its removal from the reaction solution. It can be assumed that the reaction rate is first-order in both the concentration of A (c) and B (C), and so second-order overall (2) The batch process consists of the following FOUR steps: Initially, the tank is empty 1. Fill tank with solution (ethanol/A/B). Increase temperature of the feed from 20C to 50C (1 hour) 2. Reaction takes place isothermally at 50C (4 hours, to give conversion of 50%) 3. Filtration of reaction solution to give product P (2 hours) 4. Drying with hot nitrogen gas followed by the removal of powder product (3 hours) Valve V2 to allow input of Valve V1 nitrogen gas (Stage 4) to allow input of foed Filter for (ethanol filtration B) Heating/cooling Valve V3 to allow draining of solution coil ethanol (wash) or nitrogen purge 6. The filtrate containing the unreacted A and B) is then returned to the reaction vessel where the components are topped up to the initial amounts specified above. The time for the transfer and top-up can be neglected. The whole process is then repeated. Stage 1 Stage 2 Stage 3 Stage 4 Stage 1 Images of hold-up in tank at different stages of the batch process Ethanol fitrate is then stored before return for the next batch Information on stages 1. It can be assumed that the heating time for Stage 1 (t.) is proportional to the change in temperature (which is 30C in the case above). This would assume a constant-power heater. The heat capacity of the solution can be taken to be 500 kJ/K. 2. For a batch reactor, assuming an overall second-order dependency, the reaction time (te) is related to the fractional conversion () by: 1 x 12 (3) kcal 1 x where k is the rate constant (which increases with temperature) and (c), is the initial concentration of component A. At the completion of the reaction, the final concentration and amount of product are end and (Opens respectively 3. For batch filtration, the filtration time (6) is defined as the time taken for the entire solvent to pass through the filter case, which will increase with volume of filtrate. As the filter cake increases in depth, so does the resistance to flow which will give a reduction in volumetric flowrate. From Darcy's law and constant AP filtration, it can be shown that: (ne)ond Vand (4) The final filtrate (Ve) is assumed to be 500 L for the above case. As an example, if the volume is doubled, keeping the concentration the same, the filtration time will be quadrupled. 4. Because an excess amount of hot gas is used - the product should be bone dry for quality control purposes - the drying time () can be considered to be independent of the final cake thickness, and the large value is for product quality reasons. 5. For ethanol, the maximum solubility values are 0.6 moll and 0.25 mol/L for components A and B respectively at 50C. These are the maximum amounts that will dissolve in the solvent. If more A and B is added, this will remain in the solid phase. Questions 1. Based on the information given previously, we would like to quantify the process and this is obtained by the following: 0 Calculate the cycle time (CT) and production rate for product P (moles) per 24 hours. Show how the process can be represented on a Gantt chart. (I) Will the fact that product Pis sparingly soluble affect the calculation of production rate? Propanol is suggested as an alternative solvent to ethanol. In propanol, product P can be considered insoluble, although the maximum solubilities of A and B are about one quarter the values in ethanol. (m) How would you compare ethanol and propanol as competing solvents? 2. In seeking new business, a potential new customer is interested in taking the entire output of P from the batch plant. However, because of concerns about final dryness of the product, an extra requirement would be for an extra two hours of drying time. However, the customer is prepared to pay a premium of 25% to the standard price per mole. Calculate the new cycle time (CT) and production rate per 24 hours. ) Would it be wise to switch supplying to this new customer