Answered step by step

Verified Expert Solution

Question

1 Approved Answer

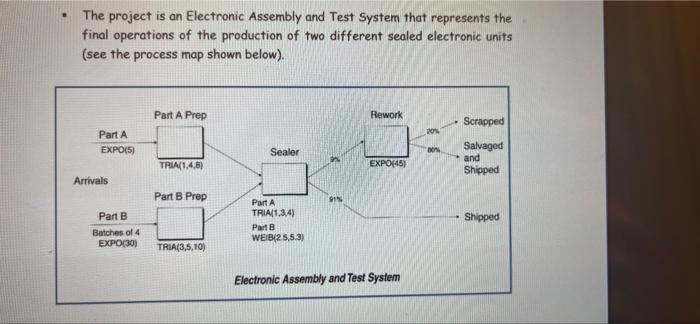

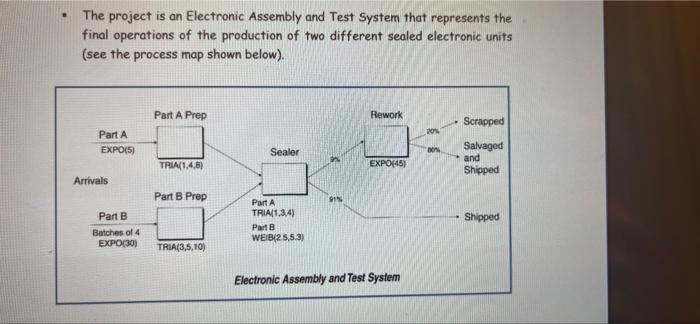

ARENA The project is an Electronic Assembly and Test System that represents the final operations of the production of two different sealed electronic units (see

ARENA

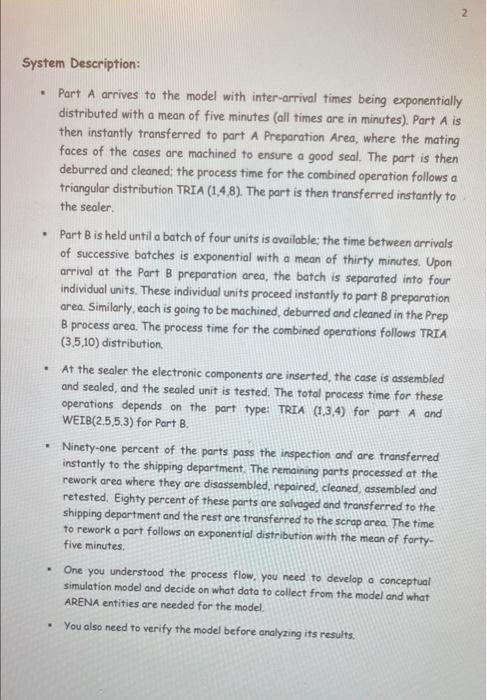

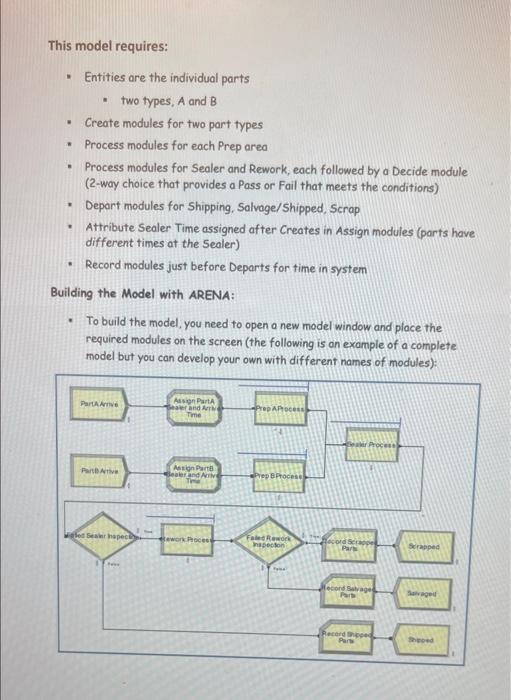

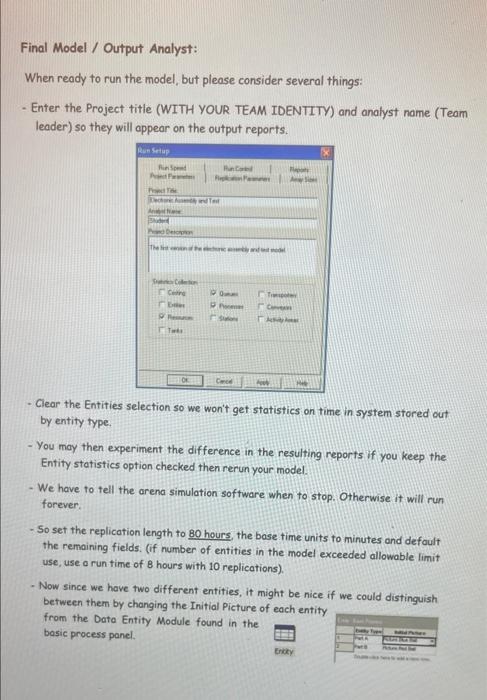

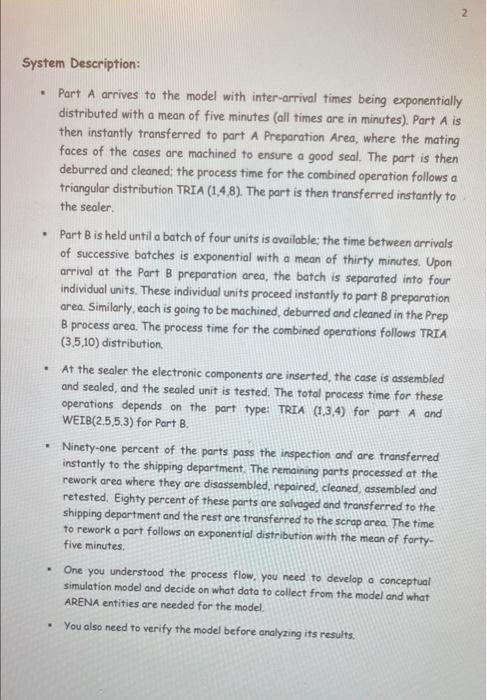

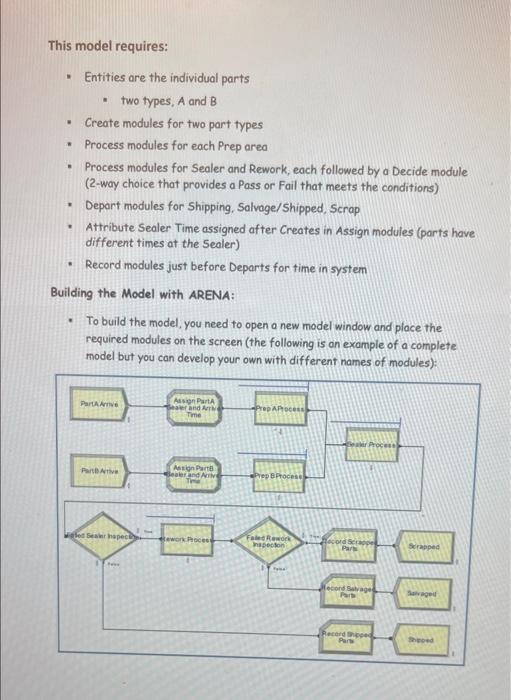

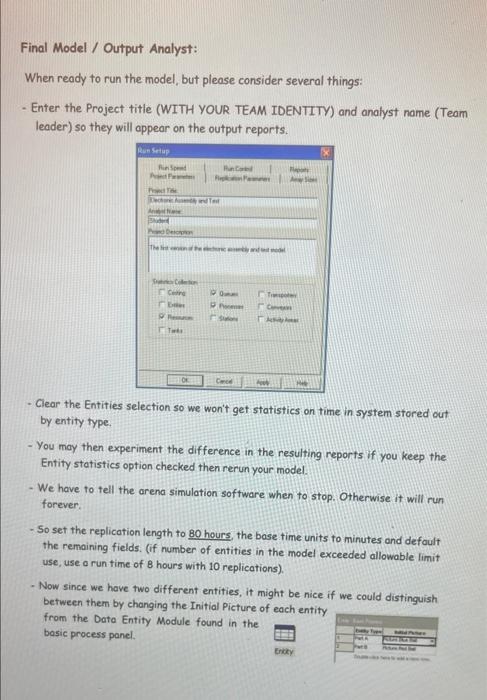

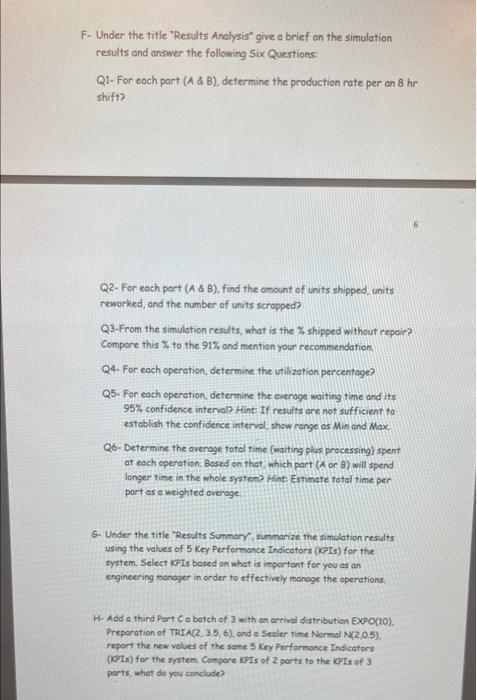

The project is an Electronic Assembly and Test System that represents the final operations of the production of two different sealed electronic units (see the process map shown below). Part A Prep Rework Scrapped Don Part A EXPO(5) Sealer Salvaged and Shipped TRIA(1.4.8) EXPO(45) Arrivals Part B Prep Part A TRIA 1.3.4) Part WEIB/25,5.3) Part B Batches of 4 EXPO(30) Shipped TRIA(3,5,10) Electronic Assembly and Test System 2 System Description: Part A arrives to the model with inter-arrival times being exponentially distributed with a mean of five minutes (all times are in minutes). Part A is then instantly transferred to part A Preparation Area, where the mating faces of the cases are machined to ensure a good seal. The part is then deburred and cleaned; the process time for the combined operation follows a triangular distribution TRIA (1.4 8). The part is then transferred instantly to the sealer. Part B is held until a batch of four units is available: the time between arrivals of successive batches is exponential with a mean of thirty minutes. Upon arrival at the Part B preparation area, the batch is separated into four individual units. These individual units proceed instantly to part B preparation area. Similarly, each is going to be machined, deburred and cleaned in the Prep B process area. The process time for the combined operations follows TRIA (3,5,10) distribution At the sealer the electronic components are inserted the case is assembled and sealed, and the sealed unit is tested. The total process time for these operations depends on the part type: TRIA (1,3,4) for part A and WEIB(2.5,5,3) for Part B. Ninety-one percent of the parts pass the inspection and are transferred instantly to the shipping department. The remaining parts processed at the rework area where they are disassembled, repaired, cleaned assembled and retested. Eighty percent of these parts are salvaged and transferred to the shipping department and the rest are transferred to the scrap area. The time to rework a part follows an exponential distribution with the mean of forty- five minutes One you understood the process flow, you need to develop a conceptual simulation model and decide on what data to collect from the model and what ARENA entities are needed for the model. You also need to verify the model before analyzing its results. . This model requires: Entities are the individual parts two types, A and B Create modules for two part types Process modules for each Prep area Process modules for Sealer and Rework, each followed by a Decide module (2-way choice that provides a Pass or Fail that meets the conditions) Depart modules for Shipping, Salvage/Shipped, Scrap Attribute Sealer Time assigned after Creates in Assign modules (parts have different times at the Sealer) Record modules just before Departs for time in system Building the Model with ARENA: To build the model, you need to open a new model window and place the required modules on the screen (the following is an example of a complete model but you can develop your own with different names of modules): Part Asian Part and ATM Time Prep Ances Part Assign Part Bestand T Prep B Process en Saker hapes w Process FaRework Docton Accord Par Scrapped econd Savage Part Savage Record Par Final Model / Output Analyst: When ready to run the model, but please consider several things: - Enter the Project title (WITH YOUR TEAM IDENTITY) and analyst name (Team leader) so they will appear on the output reports. Run Setup Deropon This he C T F FT Comed - Clear the Entities selection so we won't get statistics on time in system stored out by entity type. - You may then experiment the difference in the resulting reports if you keep the Entity statistics option checked then rerun your model. We have to tell the arena simulation software when to stop. Otherwise it will run forever - So set the replication length to 80 hours, the base time units to minutes and default the remaining fields. (if number of entities in the model exceeded allowable limit use, use a run time of 8 hours with 10 replications). - Now since we have two different entities, it might be nice if we could distinguish between them by changing the Initial Picture of each entity from the Data Entity Module found in the basic process panel Ency F- Under the title "Results Analysis" give a brief on the simulation results and answer the following Six Questions Q1- For each part (A & B), determine the production rate per an 8 hr shift? 6 Q2- For each part (A & B), find the amount of units shipped units reworked, and the number of units scrapped? Q3-From the simulation results, what is the shipped without repair? Compare this % to the 91% and mention your recommendation, Q4. For each operation, determine the utilization percentage? Q5. For each operation, determine the average waiting time and its 95% confidence interval Hint: If results are not sufficient to establish the confidence interval show range as Min and Max Q6- Determine the average total time (waiting plus processing) spent at each operation Based on that which part (or B) will spend longer time in the whole system Hint Estimate total time per part as a weighted average G- Under the title "Results Summary sommarize the simulation results using the values of 5 Key Performance Indicators (KPIs) for the system. Select KPIs based on what is important for you as an engineering manager in order to effectively manage the operations - Add a third Part Ca batch of 3 with an arrival distribution EXPO(10). Preparation of TRIA(2, 3.5, 6), and a Sealer time Normal (2.0.5). report the new values of the some 5 Key Performance Indicators (KPIS) for the system. Compare OPIs of 2 parts to the KPIs of 3 parts, what do you conclude

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started