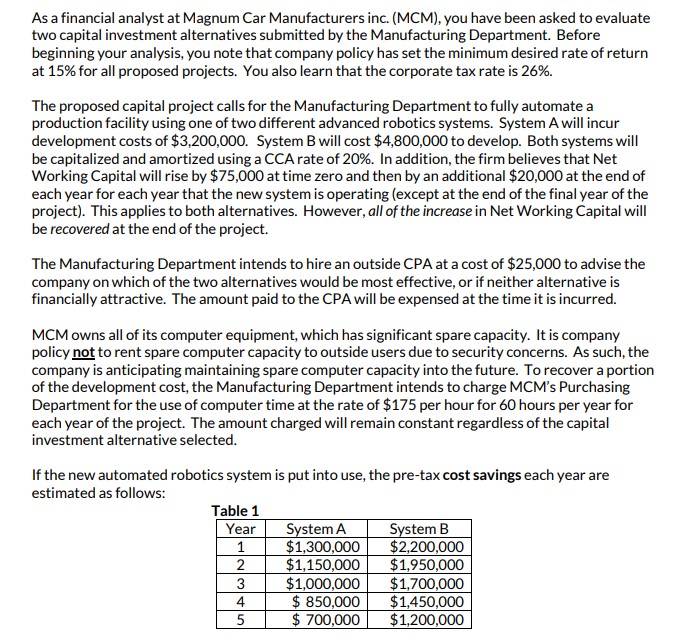

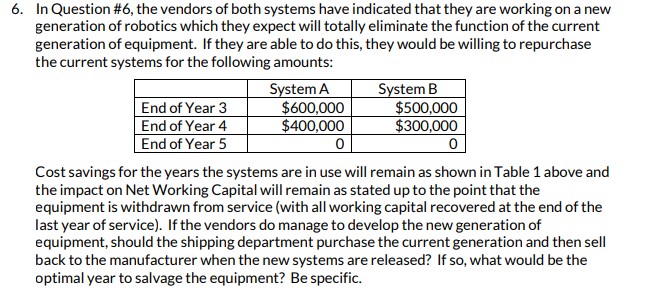

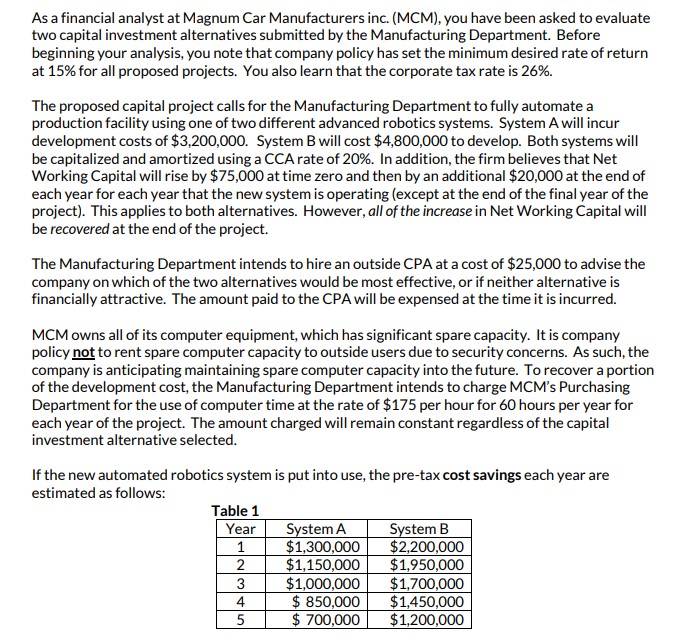

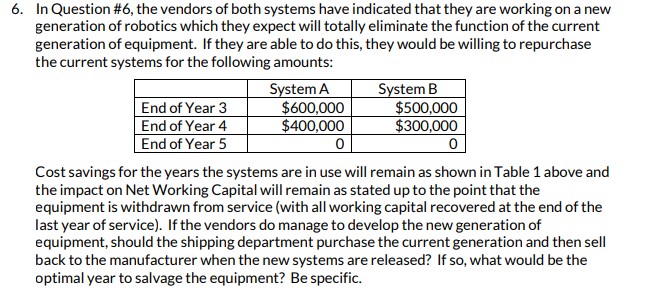

As a financial analyst at Magnum Car Manufacturers inc. (MCM), you have been asked to evaluate two capital investment alternatives submitted by the Manufacturing Department. Before beginning your analysis, you note that company policy has set the minimum desired rate of return at 15% for all proposed projects. You also learn that the corporate tax rate is 26%. The proposed capital project calls for the Manufacturing Department to fully automate a production facility using one of two different advanced robotics systems. System A will incur development costs of $3,200,000. System B will cost $4,800,000 to develop. Both systems will be capitalized and amortized using a CCA rate of 20%. In addition, the firm believes that Net Working Capital will rise by $75,000 at time zero and then by an additional $20,000 at the end of each year for each year that the new system is operating (except at the end of the final year of the project). This applies to both alternatives. However, all of the increase in Net Working Capital will be recovered at the end of the project. The Manufacturing Department intends to hire an outside CPA at a cost of $25,000 to advise the company on which of the two alternatives would be most effective, or if neither alternative is financially attractive. The amount paid to the CPA will be expensed at the time it is incurred. MCM owns all of its computer equipment, which has significant spare capacity. It is company policy not to rent spare computer capacity to outside users due to security concerns. As such, the company is anticipating maintaining spare computer capacity into the future. To recover a portion of the development cost, the Manufacturing Department intends to charge MCM's Purchasing Department for the use of computer time at the rate of $175 per hour for 60 hours per year for each year of the project. The amount charged will remain constant regardless of the capital investment alternative selected. If the new automated robotics system is put into use, the pre-tax cost savings each year are estimated as follows: Table 1 Year System A System B 1 $1,300,000 $2,200,000 2 $1,150,000 $1,950,000 3 $1,000,000 $1,700,000 4 $ 850,000 $1,450,000 5 $ 700,000 $1,200,000 6. In Question #6, the vendors of both systems have indicated that they are working on a new generation of robotics which they expect will totally eliminate the function of the current generation of equipment. If they are able to do this, they would be willing to repurchase the current systems for the following amounts: System A System B End of Year 3 $600,000 $500,000 End of Year 4 $400,000 $300,000 End of Year 5 0 0 Cost savings for the years the systems are in use will remain as shown in Table 1 above and the impact on Net Working Capital will remain as stated up to the point that the equipment is withdrawn from service (with all working capital recovered at the end of the last year of service). If the vendors do manage to develop the new generation of equipment, should the shipping department purchase the current generation and then sell back to the manufacturer when the new systems are released? If so, what would be the optimal year to salvage the equipment? Be specific. As a financial analyst at Magnum Car Manufacturers inc. (MCM), you have been asked to evaluate two capital investment alternatives submitted by the Manufacturing Department. Before beginning your analysis, you note that company policy has set the minimum desired rate of return at 15% for all proposed projects. You also learn that the corporate tax rate is 26%. The proposed capital project calls for the Manufacturing Department to fully automate a production facility using one of two different advanced robotics systems. System A will incur development costs of $3,200,000. System B will cost $4,800,000 to develop. Both systems will be capitalized and amortized using a CCA rate of 20%. In addition, the firm believes that Net Working Capital will rise by $75,000 at time zero and then by an additional $20,000 at the end of each year for each year that the new system is operating (except at the end of the final year of the project). This applies to both alternatives. However, all of the increase in Net Working Capital will be recovered at the end of the project. The Manufacturing Department intends to hire an outside CPA at a cost of $25,000 to advise the company on which of the two alternatives would be most effective, or if neither alternative is financially attractive. The amount paid to the CPA will be expensed at the time it is incurred. MCM owns all of its computer equipment, which has significant spare capacity. It is company policy not to rent spare computer capacity to outside users due to security concerns. As such, the company is anticipating maintaining spare computer capacity into the future. To recover a portion of the development cost, the Manufacturing Department intends to charge MCM's Purchasing Department for the use of computer time at the rate of $175 per hour for 60 hours per year for each year of the project. The amount charged will remain constant regardless of the capital investment alternative selected. If the new automated robotics system is put into use, the pre-tax cost savings each year are estimated as follows: Table 1 Year System A System B 1 $1,300,000 $2,200,000 2 $1,150,000 $1,950,000 3 $1,000,000 $1,700,000 4 $ 850,000 $1,450,000 5 $ 700,000 $1,200,000 6. In Question #6, the vendors of both systems have indicated that they are working on a new generation of robotics which they expect will totally eliminate the function of the current generation of equipment. If they are able to do this, they would be willing to repurchase the current systems for the following amounts: System A System B End of Year 3 $600,000 $500,000 End of Year 4 $400,000 $300,000 End of Year 5 0 0 Cost savings for the years the systems are in use will remain as shown in Table 1 above and the impact on Net Working Capital will remain as stated up to the point that the equipment is withdrawn from service (with all working capital recovered at the end of the last year of service). If the vendors do manage to develop the new generation of equipment, should the shipping department purchase the current generation and then sell back to the manufacturer when the new systems are released? If so, what would be the optimal year to salvage the equipment? Be specific