Question

As NoBull founder Crissanne Raymond examined the companys kitchen, she knew that she and her daughters could use some help with operations. NoBull, a new,

As NoBull founder Crissanne Raymond examined the companys kitchen, she knew that she and her daughters could use some help with operations. NoBull, a new, Charlottesville-based vegetarian burger producer, was at a critical junction in its development. While the business had grown substantially over the past year, it faced a number of challenges as it continued to expand its sales outside the Charlottesville region. In particular, as the burgers increased in popularity, the owners were unsure as to whether current production could keep pace with demand. The Raymonds knew that, in order to reach NoBulls eventual goal to expand nationwide, they had to better understand both NoBulls current capacity as well as its future operational requirements.

Background

NoBull Burger1 (NoBull) was started by Charlottesville native Crissanne Raymond. Crissanne had run her own successful catering business for years when, in 2011, she saw an opportunity to start a new venture based on her vegetarian burger recipe, one that had been inspired by the memory of her mothers lentil soup. To launch NoBull, Crissanne had enlisted the help of two of her daughters, Heather and Elizabeth, both of whom left their own budding careers to help with the business. As Elizabeth said, [We] kept thinking, what if we dont do this? We might miss out on a big adventure! NoBulls target customers were a mix of vegetarians,2 health-conscious consumers, and people who were just looking for a tasty burger not made of meat. Broadly speaking, NoBull competed in the meat substitute category, which included such foods as tofu and tempeh as well as vegetarian burgers. In 2011, US meat substitute sales grew to $277 million, an increase of 10% since 2008.3 Within the vegetarian burger market, three companiesGardenburger, Morningstar Farms, and Boca Burgerdominated with an 88% market share. The remaining 12% of vegetarian burger sales came from many smaller companies.4 NoBull burgers were low-fat, whole-grain burgers, and as Crissanne said, [Its] dinner in under 10 minutes. From the customers perspective, one of the major advantages of NoBull burgers compared to other vegetarian burgers was the homemade process used to create them. This hallmark style could be seen in the physical appearance of the burgers. Whereas competitors burgers often looked processed with no distinguishable ingredients, customers could actually see the lentil beans, spinach, and other ingredients that went into NoBull burgers (Exhibit 1). To showcase this quality, NoBull burgers were packaged in clear plastic containers. Initially, Crissanne and her daughters had sold the burgers through the Charlottesville City Market and a few local health food stores and restaurants. But as NoBull saturated the Charlottesville market, the Raymonds began to expand their reach to nearby cities. By performing demonstrations and offering free samples in stores and supermarkets, they were able to win over customers in new locales. Within months, word spread, and NoBulls customer list grew rapidly; as stores in Richmond, Virginia, and Washington, DC, were requesting its product. While sales to retailers, restaurants, and wholesalers grew, NoBull still continued to sell directly to customers, with particularly strong sales still coming from the Charlottesville City Market. NoBull even received calls from customers across the country asking to buy the burgers. NoBull always satisfied these customers by shipping burgers in special frozen packaging. Throughout 2011, NoBull had experienced tremendous growth, with sales increasing rapidly quarter over quarter (Exhibit 2). By the end of 2011, NoBull was operating well beyond normal capacity. Excessive overtime became the norm and some orders were delayed or even canceled due to capacity constraints. At the same time, the company began to get calls from investors interested in financing the growing company. Given the high demand and positive customer feedback, the Raymonds believed there was an opportunity to take NoBull Burger nationwide. Yet with so much capital already tied up in the business and minimal cash on hand, they were nervous about taking another step without first understanding the limits of their current operations.

Current Operations

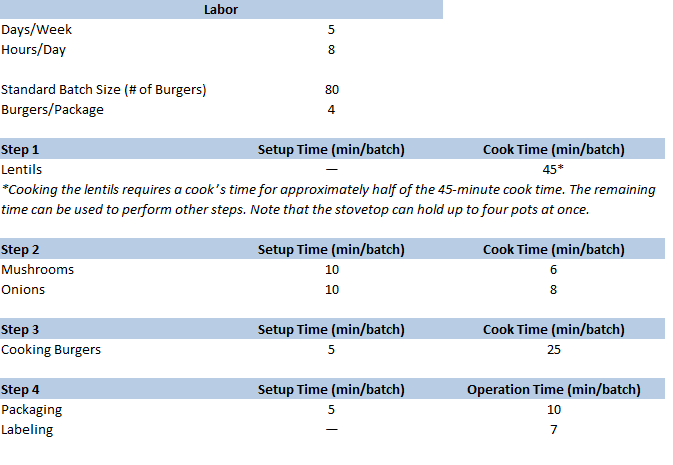

NoBulls current production process consisted of four basic steps: (1) cooking the lentils; (2) cooking additional ingredients; (3) creating the burger mix and grilling the burgers; and (4) packaging and labeling the burgers. In its kitchen, NoBull had one stove and one grill. The stovetop was used to cook the lentils (step 1); the stove oven was used to broil the additional ingredients (step 2). The grill was used to cook the burgers (step 3). Currently, NoBull made only two varieties of burgers: original and mushroom. To analyze the production process, the Raymonds chose to focus on the mushroom burger. Each batch consisted of approximately 80 burgers. The batch size had been determined roughly based on pot sizes as well as concerns about the impact a greater number of burgers per batch could have on quality. The first step in the process was to cook the lentils, which formed the base for the burger mix. One batch of lentils took approximately 25 minutes to cook. Lentils formed the basis for all of NoBulls products, and as such, quality was extremely important at this stage. The cook had to ensure that the batch of lentils was stirred gently so they would not stick to the pot and break apart. Next, the additional ingredients that would be added to the cooked lentils were prepared. For the mushroom burger, both mushrooms and onions needed to be cut and cooked. One whole pan of mushrooms and one whole pan of onions were required for each batch of mushroom burgers. It took approximately 20 minutes to clean and prep the area before work could begin on a new batch. For the cooking phase of this step, a cook placed both the pan of mushrooms and the pan of onions into the oven to broil at the same time. It took approximately 12 minutes to broil a batch of mushrooms and onions. There was only enough space in the oven for one pan of mushrooms and one pan of onions to be cooked simultaneously. Due to the short cooking times, a cook typically remained at the oven and did not multitask process steps while the ingredients broiled. After the mushrooms and onions were cooked, they were combined with the cooked lentils along with spinach, carrots, and some proprietary spices to complete the mushroom burger mixture. The mixture could be held in large plastic containers until ready for grilling, or until the end of a shift, at which time it would be placed in the refrigerator for use the next day. Next came the grilling stage. Each burger was molded by hand into a patty and placed on the grill (which was separate from the stovetop that was used to cook the lentils, mushrooms, and onions). A cook had to spend about 12 minutes cleaning and prepping before grilling a new batch of burgers. The grill had space to cook 20 burgers at a time. The grilling process took about eight minutes per 20 burgers and required a cooks full attention. Therefore, a batch of 80 burgers could be cooked in approximately 44 minutes. Grilling time included the time required to mold each burger and place it on the grill. After cooking, the burgers were removed and stacked on a sheet pan, ready to be packaged. Burgers were grouped into sets of four in preparation for packaging. Each group of four burgers was wrapped in plastic and sealed using a manual vacuum sealer. A label was then applied by hand to the package, and the final productready to be soldwas placed in a freezer.5 The packing and labeling was a manual process that took 1 minute per pack of four burgers and required about 10 minutes of preparation time to set up and recalibrate the label machine before each batch. Details for all the steps in the process are provided in Exhibit 3. Note that at the end of each day, any burgers or ingredients (e.g., a batch of burger mix) that were not completed (i.e., packaged and labeled) were considered work-in-process and refrigerated overnight for use the next day. NoBull sold the four-packs of burgers to multiple channels including the Charlottesville City Market, the Charlottesville Whole Foods, Bodos Bagels, and other local restaurants. While each channel had different costs and negotiated prices associated with it, the most common channels were wholesale (including local mom-and- pop stores, health food stores, and restaurants) and the Charlottesville City Market. For their analysis, the Raymonds assumed a four-pack of burgers currently sold for $6.00 and cost NoBull $4.50 to make. Of that cost, $2.50 was attributable to raw materials, and $2.00 was from labor, rent, and other miscellaneous costs. NoBulls kitchen operated five days per week for eight hours per day. Depending on the weekly demand, NoBull staffed the kitchen with one to two cooks. At most, two cooks could fit in the existing kitchen. The cooks were paid $12.00 an hour.

Future Growth Strategy

NoBulls current growth strategy was to continue to expand and establish its brand throughout Virginia and the DC area, targeting retailers and restaurants that were similar to its current customer base. NoBull decided to use its existing relationship with the Charlottesville Whole Foods to gain access to additional locations in Northern Virginia. The Raymonds reached out to the Northern Virginia Whole Foods regional manager, and five additional stores in the Northern Virginia/DC area agreed to stock NoBull burgers. This would allow NoBull to test new markets and to see how well its product could penetrate a more metropolitan area. While accounting for only 3% of its sales in 2011, NoBull expected its sales to Whole Foods to grow substantially by the end of 2012 with this expansion. Overall, the company expected to more than double sales in 2012 compared to 2011. At the time, NoBull was physically driving its product on a weekly basis to Northern Virginia and DC to perform sample demonstrations. To expand beyond these areas and to reach its eventual goal of selling nationwide, the company would likely need to partner with a national distributor. NoBull was still grappling with whether this was a commitment it should make. The tremendous success it had seen in its local market through word of mouth, demonstrations, and a community presence did not guarantee success outside the greater Charlottesville area. The Raymonds knew that they would lose some control over the delivery and merchandising of their product if they expanded beyond their current operational footprint. Yet if NoBull did want to become a national brand, it would need to push outside its comfort zone. In addition to the operational challenges, it would also require large investments in marketing, distribution, and personnel, not to mention a need for fresh capital to make it all happen.

Options for Increasing Capacity

While NoBull did not expect to continue growing at its current pace forever, if it continued to grow at a reasonable rate, the Raymonds knew they would eventually need more space. Their current location was extremely cramped; they did not have the space to add additional equipment or cooks. They started to look for new kitchens in the Charlottesville area, and one in particular caught their eye. It was solar-powered, had a walk-in refrigerator/freezer area and was at least three times the size of their current facility. It cost about $2,000 a month more in rent than their current facility, but it had plenty of room for the stove, the grill, and four cooks, each of whom would have a dedicated work space. As demand increased, another option for NoBull to explore was to improve operations through automation. On this front, there were many options within the food industrycooling racks, food processing equipment, automated packagers, and so on. One such machine the company was considering was a lentil steamer that would steam a batch of lentils in just 10 minutes without the use of a stovetop burner. This machine cost around $20,000. The lentil steamer might be more efficient, but the Raymonds were concerned that automation at this stage might affect the handmade appeal of their burgers. Another option was an automated pack-and-label machine that would run continuously and reduce the operation time down to 15 seconds per pack. The cost of an automated pack and label machine was $50,000. Finally, NoBull thought it might be possible to increase capacity by increasing the number of burgers in a batch. While the Raymonds were unsure about how this might affect the quality of their burgers, increasing the batch size might delay the need for a new facility or automation.

What to Do?

NoBull was producing anywhere from five to seven batches a day. The Raymonds thought the kitchen might be able to produce even more. They wanted to figure out how much NoBull could really produce without moving locations, purchasing equipment, or hiring more cooks. Given NoBulls tremendous first-year growth and its expected future growth, the Raymonds also figured that NoBulls demand could quickly outpace its current capacity, even if it was able to become more efficient. There was an argument to be made for renting the new facility in the near future, but it was not clear how soon they should make this investment. The Raymonds also thought that automating some of the process could help to increase NoBulls capacity, but they were wary of how that might affect NoBulls signature handmade quality. What could NoBull do to improve its current operations? What steps would it need to take if it were to continue growing to ensure that its production capacity would allow for this growth? Did it even make sense for NoBull to expand outside of the Charlottesville market where it was not as well known? The Raymonds had some difficult decisions to make.

QUESTION :

1.Considering all of these analyses and our demand forecasts for 2012, should weexpand our capacity? If so, how?

A.Should we expand into the new kitchen facility?

B.Should we invest in the automatic steamer?

C.Are there other options we havent thought of that can help us meet demand in the future

Labor Days/Week 5 Hours/Day 8 Standard Batch Size (\# of Burgers) 80 Burgers/Package 4 Step1LentilsSetupTime(min/batch)CookTime(min/batch)45 *Cooking the lentils requires a cook's time for approximately half of the 45-minute cook time. The remaining time can be used to perform other steps. Note that the stovetop can hold up to four pots at once. Step2MushroomsOnionsSetupTime(min/batch)1010CookTime(min/batch)68 Step3CookingBurgersStep4PackagingLabelingSetupTime(min/batch)5SetupTime(min/batch)5CookTime(min/batch)25OperationTime(min/batch)107Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started