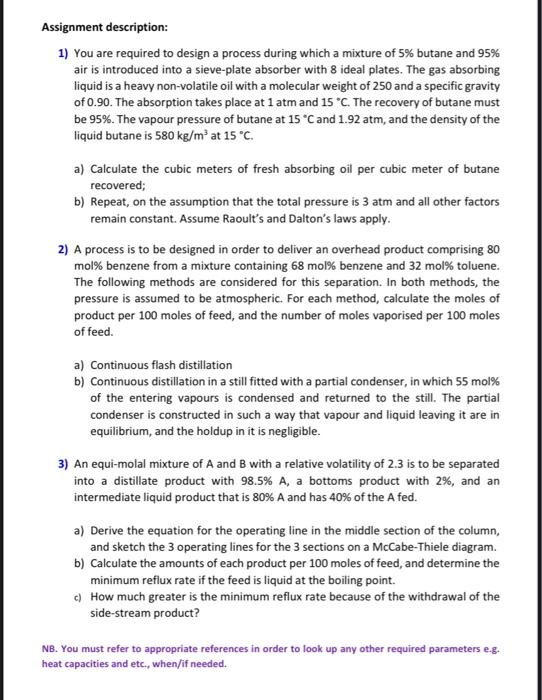

Assignment description: 1) You are required to design a process during which a mixture of 5% butane and 95% air is introduced into a sieve-plate absorber with 8 ideal plates. The gas absorbing liquid is a heavy non-volatile oil with a molecular weight of 250 and a specific gravity of 0.90. The absorption takes place at 1 atm and 15 C. The recovery of butane must be 95%. The vapour pressure of butane at 15 C and 1.92 atm, and the density of the liquid butane is 580 kg/m at 15 C. a) Calculate the cubic meters of fresh absorbing oil per cubic meter of butane recovered; b) Repeat, on the assumption that the total pressure is 3 atm and all other factors remain constant. Assume Raoult's and Dalton's laws apply. 2) A process is to be designed in order to deliver an overhead product comprising 80 mol% benzene from a mixture containing 68 mol% benzene and 32 mol% toluene. The following methods are considered for this separation. In both methods, the pressure is assumed to be atmospheric. For each method, calculate the moles of product per 100 moles of feed, and the number of moles vaporised per 100 moles of feed. a) Continuous flash distillation b) Continuous distillation in a still fitted with a partial condenser, in which 55 mol% of the entering vapours is condensed and returned to the still. The partial condenser is constructed in such a way that vapour and liquid leaving it are in equilibrium, and the holdup in it is negligible. 3) An equi-molal mixture of A and B with a relative volatility of 2.3 is to be separated 2 into a distillate product with 98.5% A, a bottoms product with 2%, and an intermediate liquid product that is 80% A and has 40% of the A fed. a) Derive the equation for the operating line in the middle section of the column, and sketch the 3 operating lines for the 3 sections on a McCabe-Thiele diagram. b) Calculate the amounts of each product per 100 moles of feed, and determine the minimum reflux rate if the feed is liquid at the boiling point. c) How much greater is the minimum reflux rate because of the withdrawal of the side-stream product? NB. You must refer to appropriate references in order to look up any other required parameters e.g. heat capacities and etc., when/if needed