Assume that you are the Chief Purchasing Officer (CFO) of dairy products in Coles. You attended a board meeting yesterday where the next year's procurement strategies were decided:

- Ensure that suppliers have implemented the latest technologies in their supply chain.

- Work together with suppliers to ensure the best price and high quality of dairy products.

- Collaborate and support suppliers with training to strengthen their engagement in and ensure their use of sustainable practices.

- Your CEO asked you to evaluate and rank your current suppliers based on these new strategies.

Question 1

Reword the 7 steps and explain how they are applied to the scenario with exampels.

Question 2

Create challemges for the steps and then find the solutions.

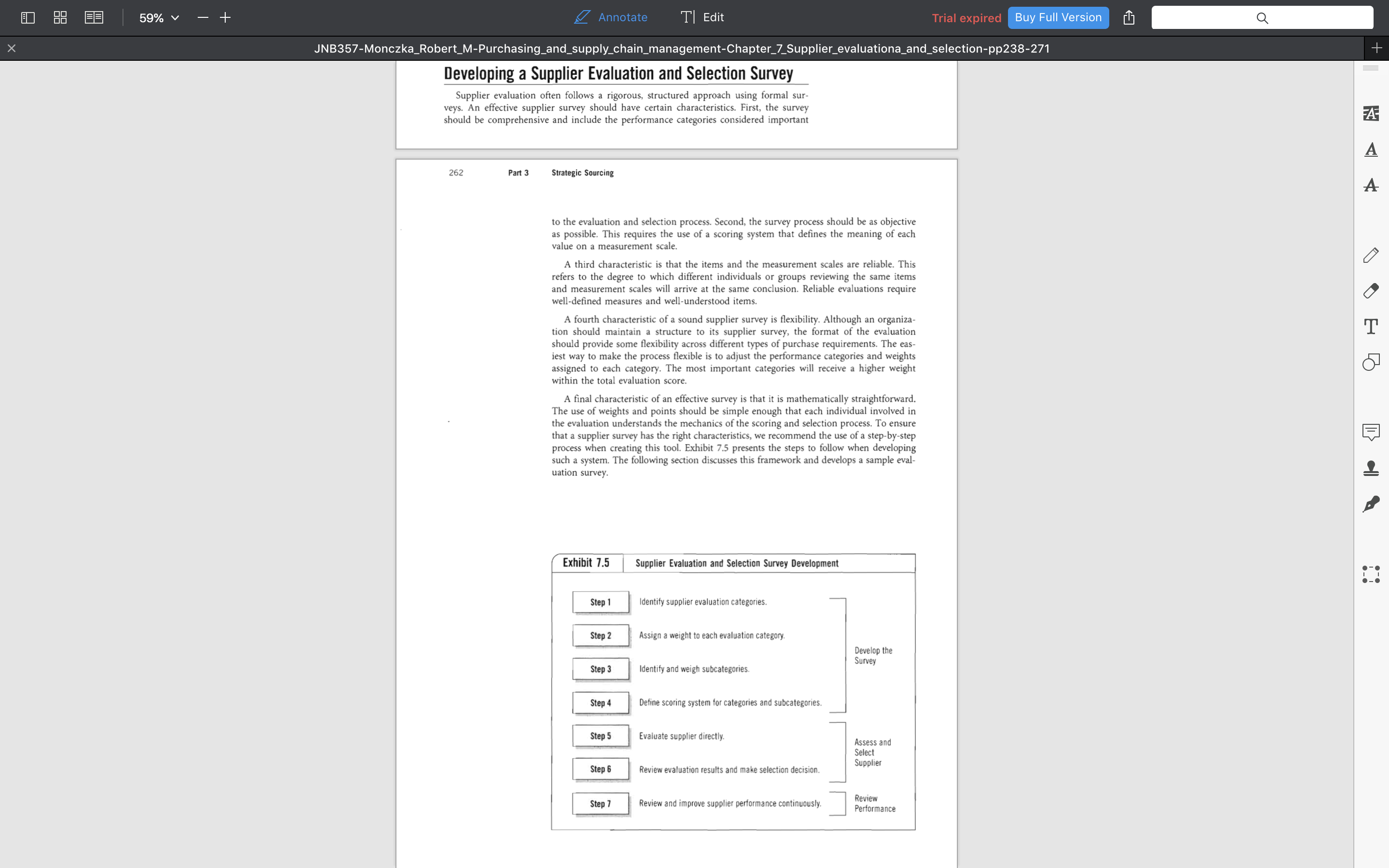

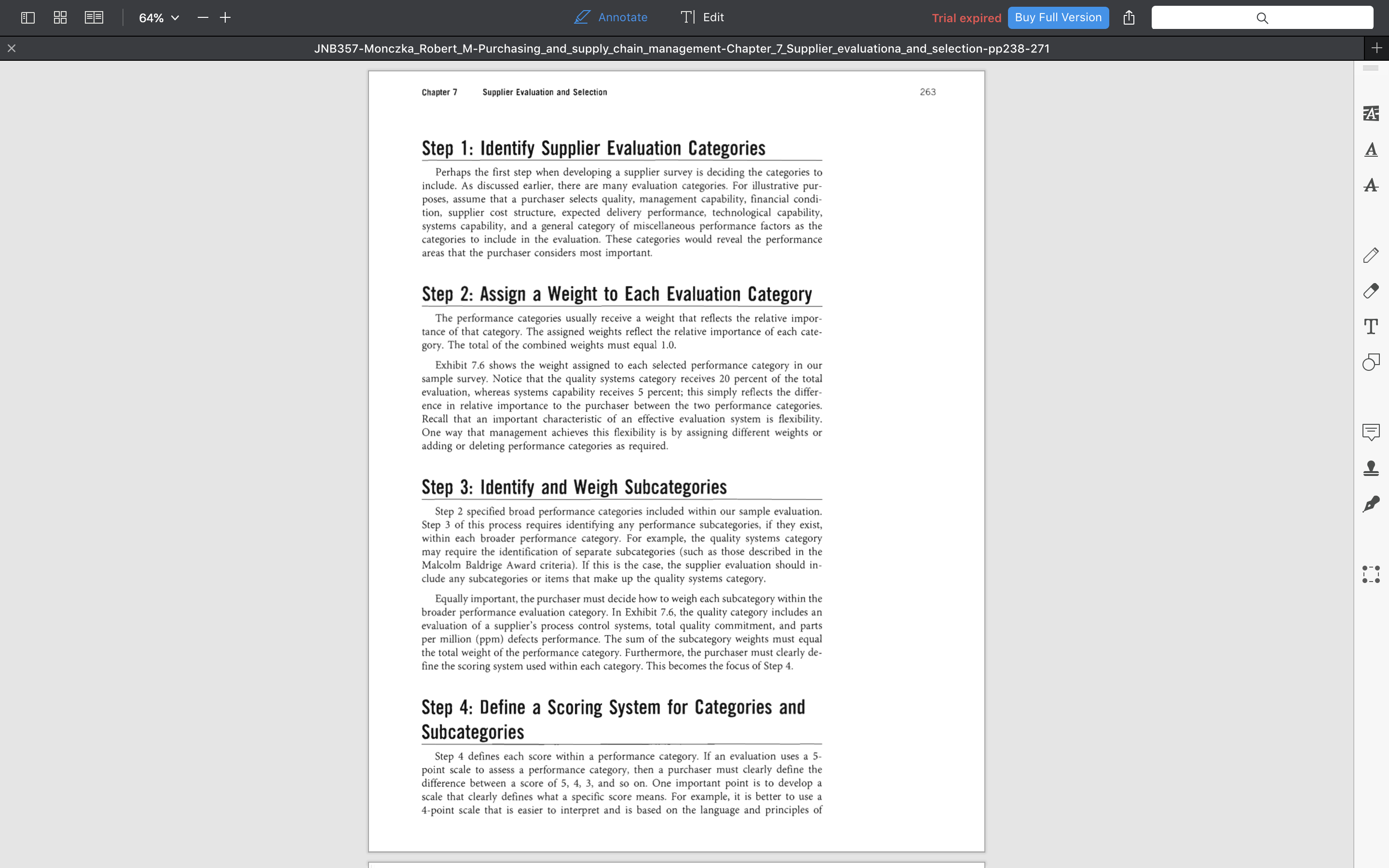

88 59% v Annotate T| Edit Trial expired Buy Full Version 2 JNB357-Monczka_Robert_M-Purchasing_and_supply_chain_management-Chapter_7_Supplier_evaluationa_and_selection-pp238-271 + Developing a Supplier Evaluation and Selection Survey Supplier evaluation often follows a rigorous, structured approach using formal sur- veys. An effective supplier survey should have certain characteristics. First, the survey should be comprehensive and include the performance categories considered important A A 262 Part 3 Strategic Sourcing A to the evaluation and selection process. Second, the survey process should be as objective as possible. This requires the use of a scoring system that defines the meaning of each value on a measurement scale. A third characteristic is that the items and the measurement scales are reliable. This refers to the degree to which different individuals or groups reviewing the same items and measurement scales will arrive at the same conclusion. Reliable evaluations require well-defined measures and well-understood items. A fourth characteristic of a sound supplier survey is flexibility. Although an organiza- tion should maintain a structure to its supplier survey, the format of the evaluation should provide some flexibility across different types of purchase requirements. The eas- jest way to make the process flexible is to adjust the performance categories and weights assigned to each category. The most important categories will receive a higher weight within the total evaluation score. A final characteristic of an effective survey is that it is mathematically straightforward The use of weights and points should be simple enough that each individual involved in the evaluation understands the mechanics of the scoring and selection process. To ensure that a supplier survey has the right characteristics, we recommend the use of a step-by-step process when creating this tool. Exhibit 7.5 presents the steps to follow when developing such a system. The following section discusses this framework and develops a sample eval- uation survey. Exhibit 7.5 Supplier Evaluation and Selection Survey Development Step 1 Identify supplier evaluation categories. Step 2 Assign a weight to each evaluation category. Develop the Survey Step 3 Identify and weigh subcategories. Step 4 Define scoring system for categories and subcategories. Step 5 Evaluate supplier directly. Assess and Select Supplier Step 6 Review evaluation results and make selection decision. Step 7 Review and improve supplier performance continuously. Review PerformanceJNBSSPMOnczkaJobertJ/lcPurchaslliglithupply/7chalerartagenielitschapterjjupp|lenevalllatl0na,arid,selectioncpt323as27l chapter 1 supplier Evalualinn and Selection 263 Step 1: Identity Supplier Evaluation Categories Perhaps the first step when developing a supplier survey is deciding the categories to include. As discussed earlier, there are many evaluation categories. For illustrative puts poses. assume that a purchaser selects quality. management capability. nancial condi- tion. supplier cost structure, expected delivery performance, technological capability. systems capability. and a general category of miscellaneous performance factors as the categories to include in the evaluation. These categories would reveal the performance areas that the purchaser considers most important. he Z1> Step 2: Assign a Weight to Each Evaluation Category The performance categories usually receive a weight that reflects the relative lmp0r~ tance of that category. The assigned weights reect the relative importance of each caie gory. The total of the combined weights must equal 1.0. %6% Exhibit 7.5 shows the weight asstgned to each selected performance category in our sample survey. Notice that the quality systems category receives 20 percent of the total evaluation, whereas systems capability receives 5 percent; this simply reects the differ ence in relative importance to the purchaser between the two performance categories. Recall that an itnportant characteristic of an effective evaluation system is exibility. One way that management achieves this exibility is by assigning different weights or adding or deleting performance categories as required. HOE Step 3: Identity and Weigh Subcategories step 2 specied broad performance categories included within our sample evaluation. Step 3 of this process requires identifying any performance subcategories. if they exist. within each broader performance category. For example. the quality systems category may require the identication of separate subcategories (such as those described in the Malcolm Baldtige Award criteria), if this is the case, the supplier evaluation should in- clude any subcategories or items that make up the quality systems category. I Equally important. the purchaser must decide how to weigh each subcategory within the broader performance evaluation category. in Exhibit 7.5, the quality category includes an evaluation of a supplier's process control systems. total quality commitment. and pans per million (PPm) detects performance. The sum of the subcategory weights must equal the total weight orthc performance category, Furthermore, the purchaser must clearly de- ne the scoring system used within each category. This becomes the focus of Step 4. Step 4: Define a Scoring System for Categories and Subcategories Step 4 denes each score within a performance category. If an evaluation uses a 5- point scale to assess a performance category. then a purchaser must clearly define the difference between a score of s, 4, 3. and so on, One important point is to develop a scale that clearly defines what a specic score means. For example, it is better to use a 4-point scale that is easier to interpret and is based on the language and principles of 88 64% v - Annotate TI Edit Trial expired Buy Full Version 2 JNB357-Monczka_Robert_M-Purchasing_and_supply_chain_management-Chapter_7_Supplier_evaluationa_and_selection-pp238-271 + 264 Part 3 Strategic Sourcing A Exhibit 7.6 Initial Supplier Evaluation A CATEGORY WEIGHT SUBWEIGHT SCORE (5 PT. SCALE) WEIGHTED SCORE Supplier: Advanced Micro Systems 1. Quality Systems A 20 Process control systems Total quality commitment UAA Parts-per-million defect performance 70 17 2. Management Capability 10 Management/labor relations Management capability 80 3. Financial Condition 10 Debt structure 3.0 Turnover ratios 7.0 4. Cost Structure 15 Costs relative to industry Understanding of costs Cost control/reduction efforts 140 5. Delivery Performance 15 Performance to promise Lead-time requirements www Responsiveness 9.0 6. Technical/Process Capability 15 Product innovation Process innovation Research and development 140 7. Information Systems Capability 5 EDI capability NW CAD/CAM 31 B. General 10 Support of minority suppliers Environmental compliance DOW in W N Supplier's supply base management 8.2 Max Total Points = 100 Total Weighted Score 80 6 5 point rating scale "0"= Lowest; "5" Highest total quality management than a 10-point scale where 1-2 = poor, 3-4 = weak, 5-6 = marginal, 7-8 = qualified, and 9-10 = outstanding. The scoring values on the 10-point scale do not have descriptive definitions detailing the difference between a 1 and a 2 or a and a 4, for example. A more specific way is shown in the 4-point scale below: Major nonconformity (0 points earned): The absence or total breakdown of a system to meet a requirement, or any noncompliance that would result in the probable shipment of a nonconforming product. 30 of 3788 64% v - Annotate T| Edit Trial expired Buy Full Version 2 JNB357-Monczka_Robert_M-Purchasing_and_supply_chain_management-Chapter_7_Supplier_evaluationa_and_selection-pp238-271 + Chapter 7 Supplier Evaluation and Selection 265 A Minor nonconformity (1 point earned): A noncompliance (though not major) A that judgment and experience indicate is likely to result in the failure of the quality system or reduce its ability to ensure controlled processes or products. Conformity (2 points earned): No major or minor nonconformities were noted A during the evaluation. . Adequacy (3 points earned): Specific supplier performance or documentation meets or exceeds requirements given the scope of the supplier's operations. Major conformity (4 points earned): Documentation exceeds the buyer's re- quirements, internal process monitoring system in place to guard against major systems breakdowns, and total quality management system insures that only good parts will be made and shipped. A well-defined scoring system takes criteria that may be highly subjective and devel- ops a quantitative scale for measurement. Effective metrics allow different individuals to interpret and score similarly the same performance categories under review. A scoring system that is too broad, ambiguous, or poorly defined increases the probability of arriv- ing at widely different assessments or conclusions. Step 5: Evaluate Supplier Directly This step requires that the reviewer visit a supplier's facilities to perform the evalua tion. Site visits require at least a day, and often several days, to complete. When factoring in travel time and post-visit reviews, it becomes clear that an organization must carefully select those suppliers it plans on evaluating. In many cases, a cross-functional team will perform the evaluation, which allows team members with different knowledge to ask dif- ferent questions. Purchasers often notify suppliers beforehand of any documentation required during the initial evaluation. For example, if a purchaser has no previous experience with a sup- plier, the reviewer might require a supplier to provide documentation of performance capability. The supplier will have to present evidence of process capability studies, pro- cess control systems, or delivery performance. The following explains the calculation for the quality category in Exhibit 7.6: Quality Systems Performance Category (Weight = 20 percent of total evaluation). Subcategories are the following: Process control systems (4 points out of 5 possible points equals 80 percent) or 0.8 x 5 sub-weight = 4.0 points . Total quality commitment (4 points out of 5 possible points) = 0.8 x 8 sub-weight = 6.4 points PPM defect performance (5 points out of 5 possible points) = 1.0 x 7 sub-weight = 7.0 points . Total for category = 17.4 points or 87 percent of total possible points (17.4/20) As shown in Exhibit 7.6, Advanced Micro Systems received a total overall evaluation of 80.6 percent. A purchaser can objectively compare the scores of different suppliers competing for the same purchase contract or select one supplier over another based on the evaluation score. It is also possible that a supplier does not qualify at this time for further purchase consideration. Purchasers should have minimum acceptable 31 of 3788 64% v - Annotate T| Edit Trial expired Buy Full Version 2 JNB357-Monczka_Robert_M-Purchasing_and_supply_chain_management-Chapter_7_Supplier_evaluationa_and_selection-pp238-271 + 266 Part 3 Strategic Sourcing A performance requirements that suppliers must satisfy before they can become part of the supply base. In this example, the supplier performs acceptably in most major categories A except delivery performance (9 out of 15 possible points). The reviewer must decide if the shortcomings in this category are correctable or if the supplier simply lacks the abil- A ity to perform. Step 6: Review Evaluation Results and Make Selection Decision At some point, a reviewer must decide whether to recommend or reject a supplier as a source. A purchaser may review a supplier for consideration for expected future business and not a specific contract. Evaluating suppliers before there is an actual purchase require ment can provide a great deal of flexibility to a purchaser. Once an actual need materializes, the purchaser is in a position to move quickly because it has prequalified the supplier. It is important to determine the seriousness of any supplier shortcomings noted dur- ing the evaluation and assess the degree to which these shortcomings might affect perfor- mance. Evaluation scales should differentiate among various degrees of supplier shortcomings. Alcoa, for example, explicitly defines the difference between a perfor- mance problem and a deficiency. A performance problem is "a discrepancy, nonconfor- mance, or missing requirement that will have a significant negative impact on an important area of concern in an audit statement." A deficiency is "a minor departure from an intended level of performance, or a nonconformance that is easily resolved and does not materially affect the required output." The primary output from this step is a recommendation about whether to accept a supplier for a purchase contract. Exhibit 7.7 illustrates a simple recommendation form issued after a supplier evaluation visit conducted by a commodity team. An important outcome from any evaluation is the identification of improvement opportunities on the part of the supplier. A purchaser may evaluate several suppliers that might be competing for the same contract. The initial evaluation provides an objective way to compare suppliers side by side before making a final selection decision. A purchaser may decide to use more than one supplier based on the results of the supplier survey. The authority to decide the final selection varies from organization to organization. The reviewer or team who evaluated the supplier may have the authority to make the supplier selection decision. In other cases, the buyer or team may present or justify the supplier se- lection decision or findings to a committee or a manager who has final authority. Step 7: Review and Improve Supplier Performance Continuously The supplier survey or visit is only the first step of the evaluation process. If a pur- chaser decides to select a supplier, the supplier must then perform according to the pur- chaser's requirements. The emphasis shifts from the initial evaluation and selection of suppliers to evidence of continuous performance improvement by suppliers. Chapter 9 addresses the management of a world-class supply base. 32 of 37