Answered step by step

Verified Expert Solution

Question

1 Approved Answer

At the end of October, Elizabeth lamented the company's situation: in the middle of production of Coronado-T's most popular long- sleeve T-shirt, the company

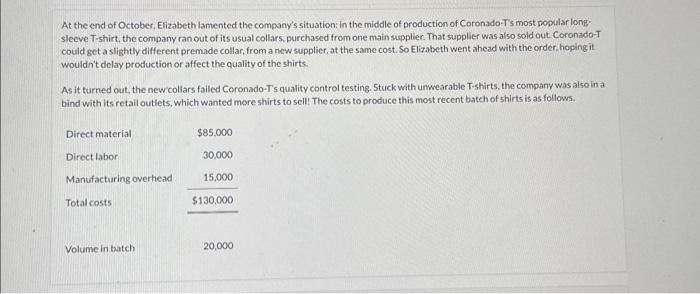

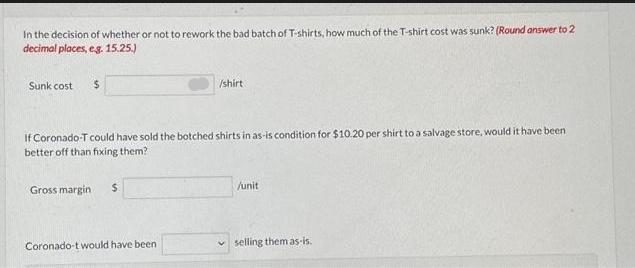

At the end of October, Elizabeth lamented the company's situation: in the middle of production of Coronado-T's most popular long- sleeve T-shirt, the company ran out of its usual collars, purchased from one main supplier. That supplier was also sold out. Coronado-T could get a slightly different premade collar, from a new supplier, at the same cost. So Elizabeth went ahead with the order, hoping it wouldn't delay production or affect the quality of the shirts. As it turned out, the new collars failed Coronado-T's quality control testing. Stuck with unwearable T-shirts, the company was also in a bind with its retail outlets, which wanted more shirts to sell! The costs to produce this most recent batch of shirts is as follows. Direct material. Direct labor Manufacturing overhead Total costs Volume in batch $85,000 30,000 15,000 $130,000 20,000 In the decision of whether or not to rework the bad batch of T-shirts, how much of the T-shirt cost was sunk? (Round answer to 2 decimal places, eg. 15.25.) Sunk cost $ Gross margin If Coronado-T could have sold the botched shirts in as-is condition for $10.20 per shirt to a salvage store, would it have been better off than fixing them? $ /shirt Coronado-t would have been /unit selling them as-is.

Step by Step Solution

★★★★★

3.38 Rating (154 Votes )

There are 3 Steps involved in it

Step: 1

In the decision of whether or not to rework the bad batch of Tshirts the ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started