Answered step by step

Verified Expert Solution

Question

1 Approved Answer

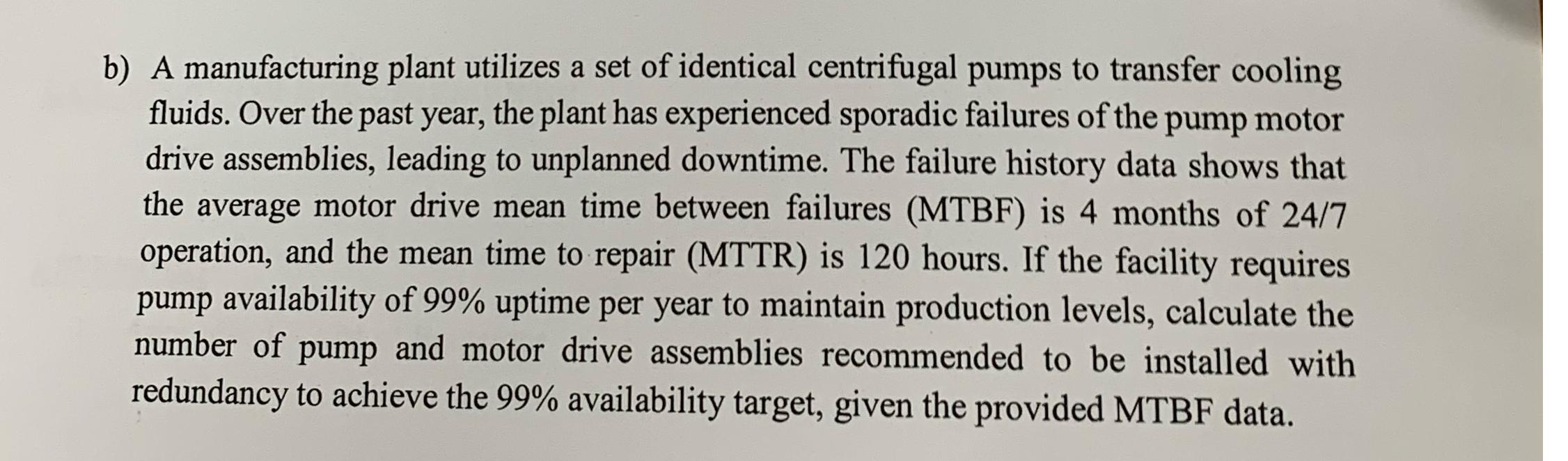

b) A manufacturing plant utilizes a set of identical centrifugal pumps to transfer cooling fluids. Over the past year, the plant has experienced sporadic

b) A manufacturing plant utilizes a set of identical centrifugal pumps to transfer cooling fluids. Over the past year, the plant has experienced sporadic failures of the pump motor drive assemblies, leading to unplanned downtime. The failure history data shows that the average motor drive mean time between failures (MTBF) is 4 months of 24/7 operation, and the mean time to repair (MTTR) is 120 hours. If the facility requires pump availability of 99% uptime per year to maintain production levels, calculate the number of pump and motor drive assemblies recommended to be installed with redundancy to achieve the 99% availability target, given the provided MTBF data.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

The question you shared is about calculating the number of pump and motor drive assemblies that a manufacturing plant should install to achieve 99 availability given specific Mean Time Between Failure...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started