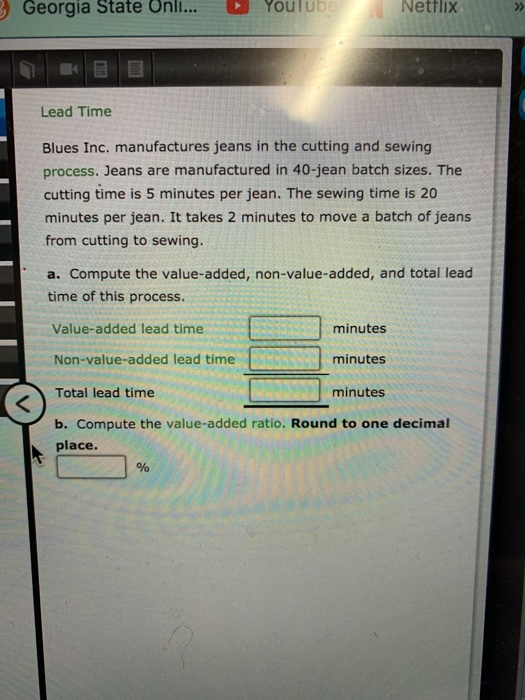

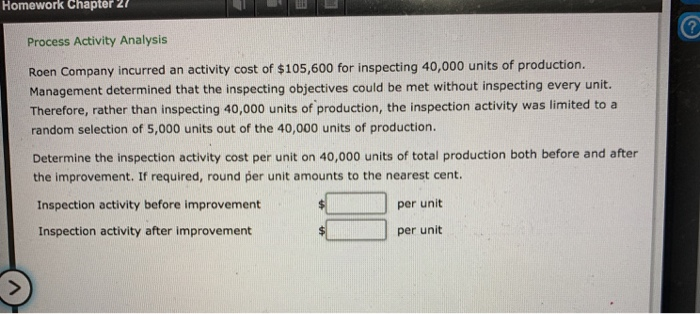

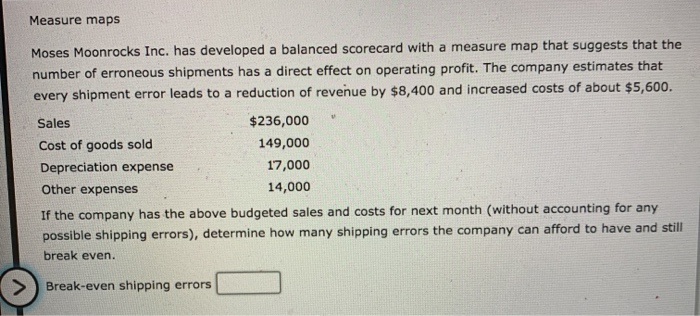

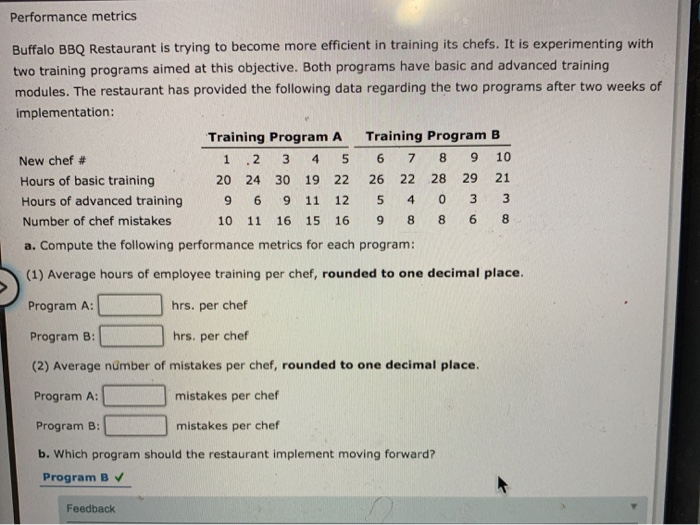

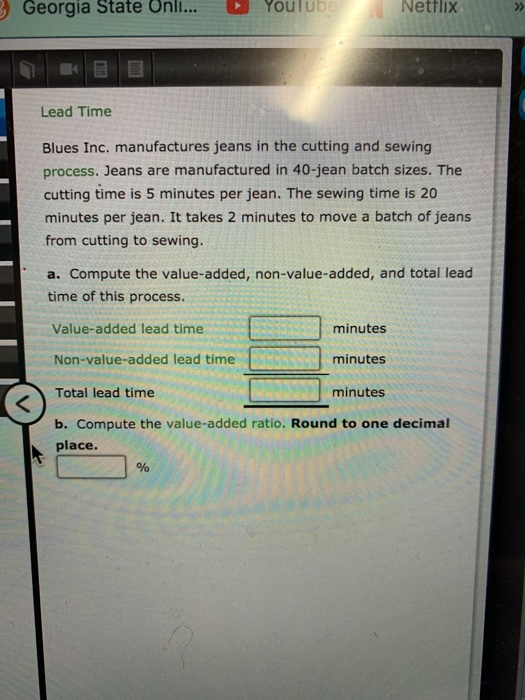

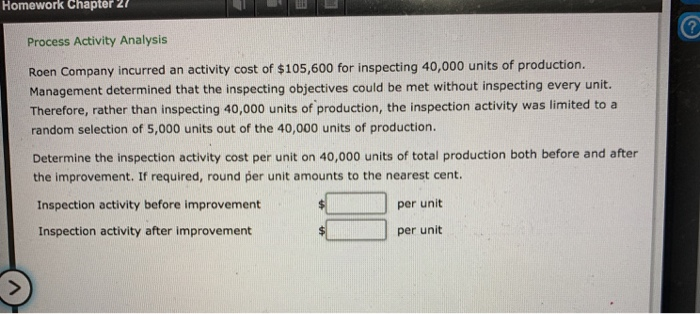

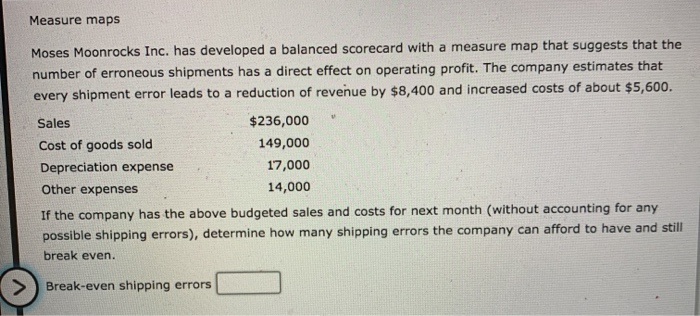

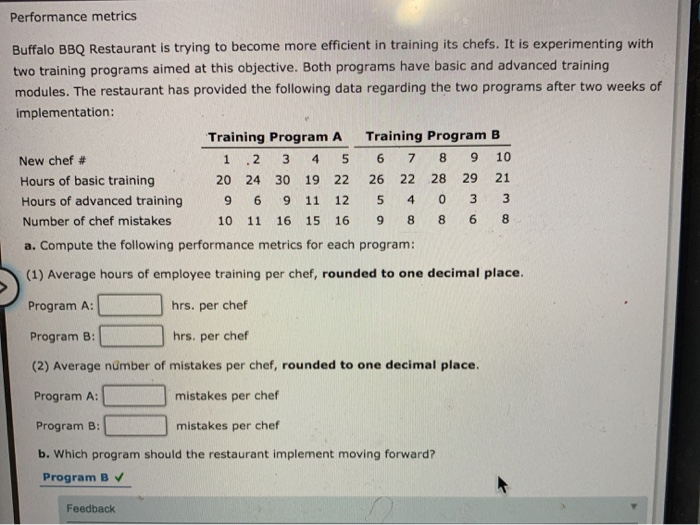

B Georgia State Onli... Youlube Netflix Lead Time Blues Inc. manufactures jeans in the cutting and sewing process. Jeans are manufactured in 40-jean batch sizes. The cutting time is 5 minutes per jean. The sewing time is 20 minutes per jean. It takes 2 minutes to move a batch of jeans from cutting to sewing. a. Compute the value-added, non-value-added, and total lead time of this process. Value-added lead time minutes Non-value-added lead time minutes Total lead time minutes b. Compute the value-added ratio. Round to one decimal place. % Homework Chapter 27 Process Activity Analysis Roen Company incurred an activity cost of $105,600 for inspecting 40,000 units of production. Management determined that the inspecting objectives could be met without inspecting every unit. Therefore, rather than inspecting 40,000 units of production, the inspection activity was limited to a random selection of 5,000 units out of the 40,000 units of production. Determine the inspection activity cost per unit on 40,000 units of total production both before and after the improvement. If required, round per unit amounts to the nearest cent. Inspection activity before improvement per unit Inspection activity after improvement per unit Measure maps Moses Moonrocks Inc. has developed a balanced Scorecard with a measure map that suggests that the number of erroneous shipments has a direct effect on operating profit. The company estimates that every shipment error leads to a reduction of revenue by $8,400 and increased costs of about $5,600. Sales $236,000 Cost of goods sold 149,000 Depreciation expense 17,000 Other expenses 14,000 If the company has the above budgeted sales and costs for next month (without accounting for any possible shipping errors), determine how many shipping errors the company can afford to have and still break even. Break-even shipping errors Performance metrics 1 Buffalo BBQ Restaurant is trying to become more efficient in training its chefs. It is experimenting with two training programs aimed at this objective. Both programs have basic and advanced training modules. The restaurant has provided the following data regarding the two programs after two weeks of implementation: Training Program A Training Program B New chef # .2 3 4 5 6 7 8 9 10 Hours of basic training 20 24 30 19 22 26 22 28 29 21 Hours of advanced training 9 6 9 11 12 5 4 0 3 3 Number of chef mistakes 10 11 16 15 16 9 8 8 6 8 a. Compute the following performance metrics for each program: (1) Average hours of employee training per chef, rounded to one decimal place. Program A: hrs. per chef Program B: hrs. per chef (2) Average number of mistakes per chef, rounded to one decimal place. Program A: mistakes per chef Program B: mistakes per chef b. Which program should the restaurant implement moving forward? Program B Feedback