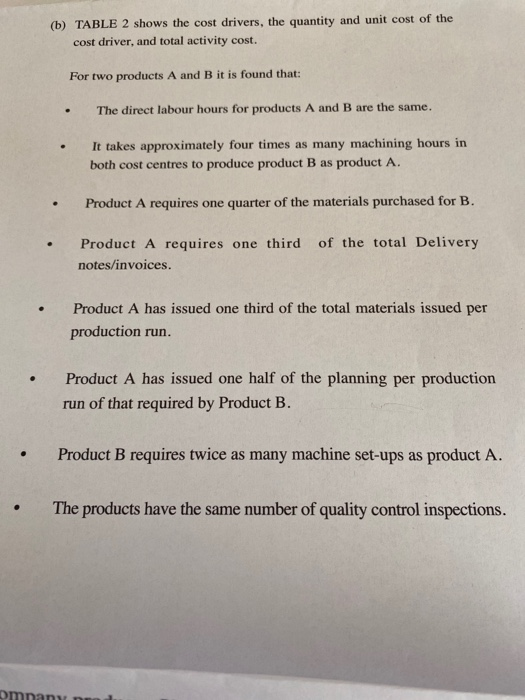

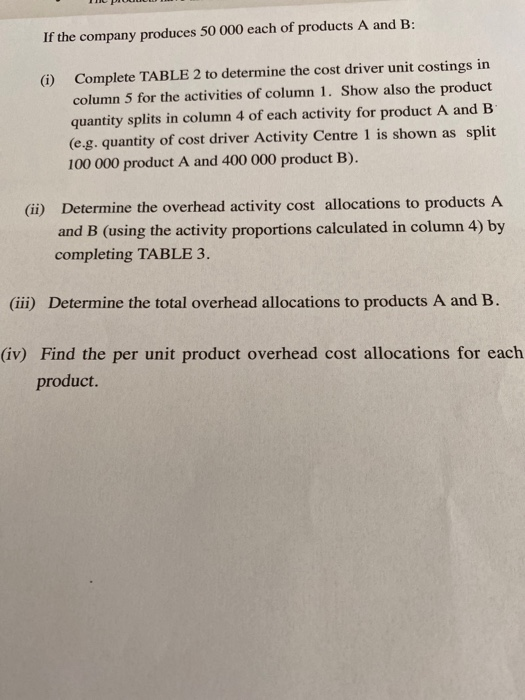

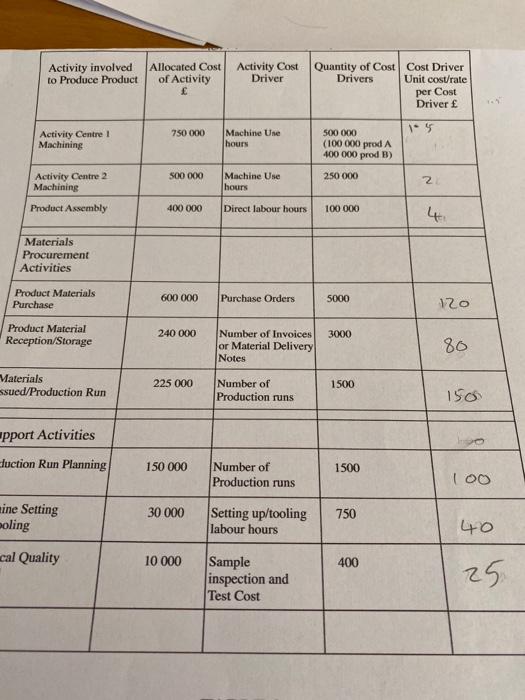

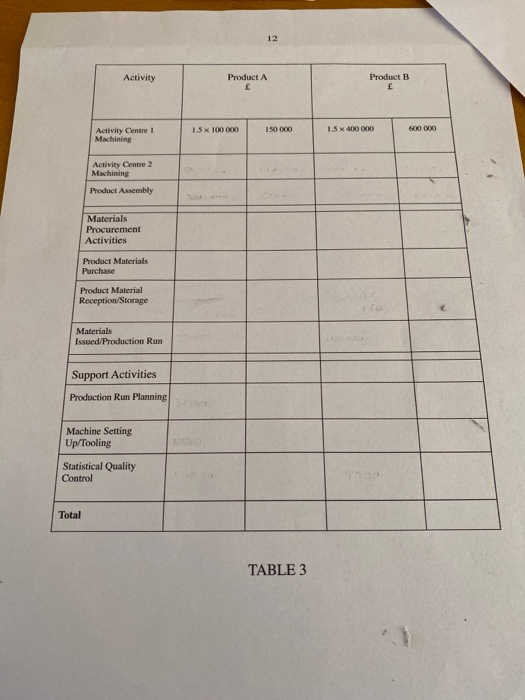

(b) TABLE 2 shows the cost drivers, the quantity and unit cost of the cost driver, and total activity cost. For two products A and B it is found that: The direct labour hours for products A and B are the same. It takes approximately four times as many machining hours in both cost centres to produce product B as product A. Product A requires one quarter of the materials purchased for B. Product A requires one third of the total Delivery notes/invoices. Product A has issued one third of the total materials issued per production run. Product A has issued one half of the planning per production run of that required by Product B. Product B requires twice as many machine set-ups as product A. The products have the same number of quality control inspections. omnany If the company produces 50 000 each of products A and B: (1) Complete TABLE 2 to determine the cost driver unit costings in column 5 for the activities of column 1. Show also the product quantity splits in column 4 of each activity for product A and B (e.g. quantity of cost driver Activity Centre 1 is shown as split 100 000 product A and 400 000 product B). (ii) Determine the overhead activity cost allocations to products A and B (using the activity proportions calculated in column 4) by completing TABLE 3. (iii) Determine the total overhead allocations to products A and B. (iv) Find the per unit product overhead cost allocations for each product. Activity involved to Produce Product Allocated Cost of Activity Activity Cost Driver Quantity of Cost Cost Driver Drivers Unit cost/rate per Cost Driver Activity Centre Machining 750 000 Machine Use hours 500 000 (100 000 prod A 400 000 prod B) SOO 000 Activity Centre 2 Machining Machine Use hours 250 000 Product Assembly 400 000 Direct labour hours 100 000 Materials Procurement Activities Product Materials Purchase 600 000 Purchase Orders 5000 12o Product Material Reception/Storage 240 000 3000 Number of Invoices or Material Delivery Notes 80 Materials ssued/Production Run 225 000 1500 Number of Production runs 150 pport Activities luction Run Planning 150 000 Number of Production runs 1500 100 ine Setting oling 30 000 Setting up/tooling labour hours 750 40 cal Quality 10 000 400 Sample inspection and Test Cost 25 Activity Product A Product B Activity Centre Machining 1.3 100 000 150 000 15x400000 600 000 Activity Centre 2 Machining Product Assembly Materials Procurement Activities Product Materials Purchase Product Material Reception Storage Materials Issued/Production Run Support Activities Production Run Planning Machine Setting Up Tooling Statistical Quality Control Total TABLE 3