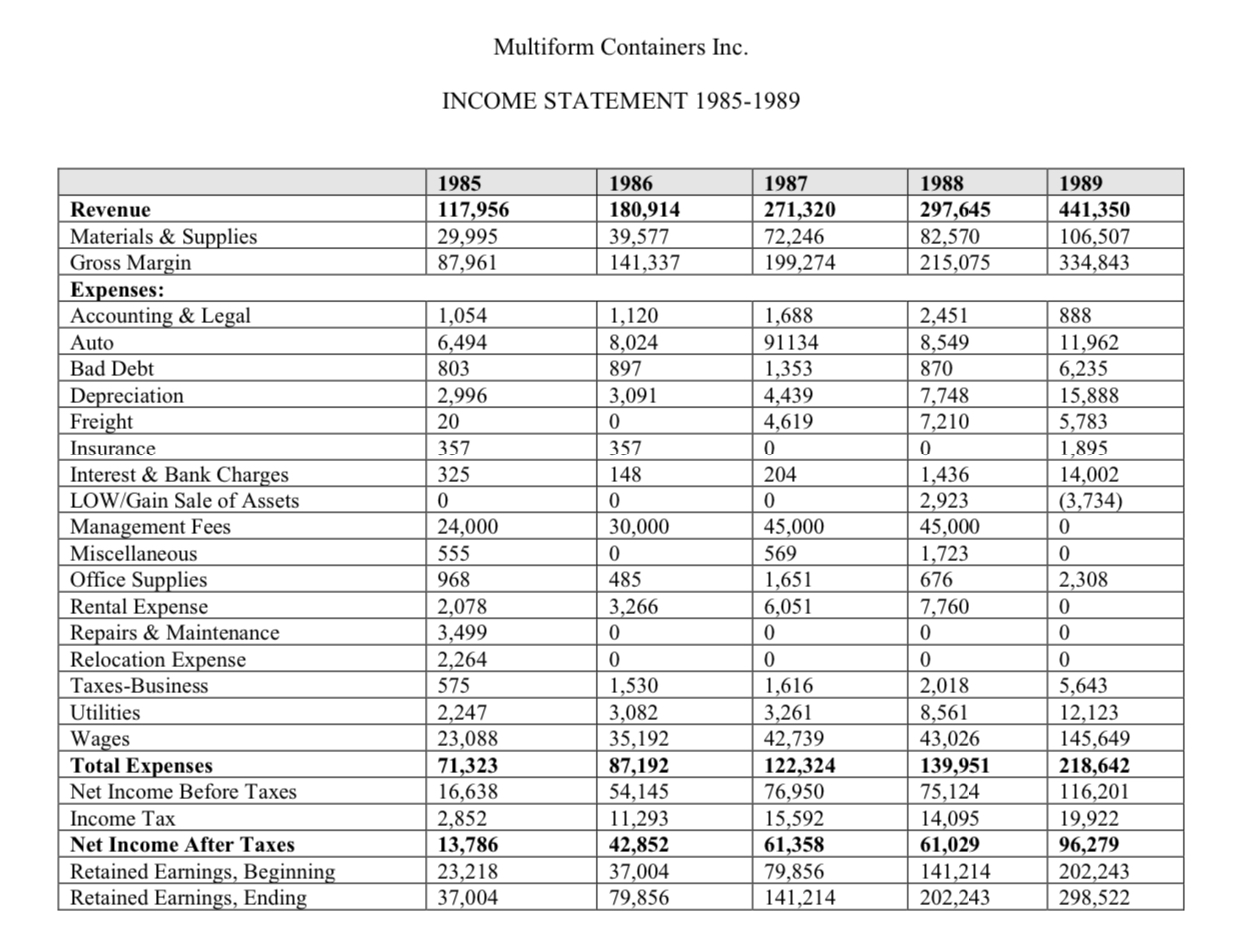

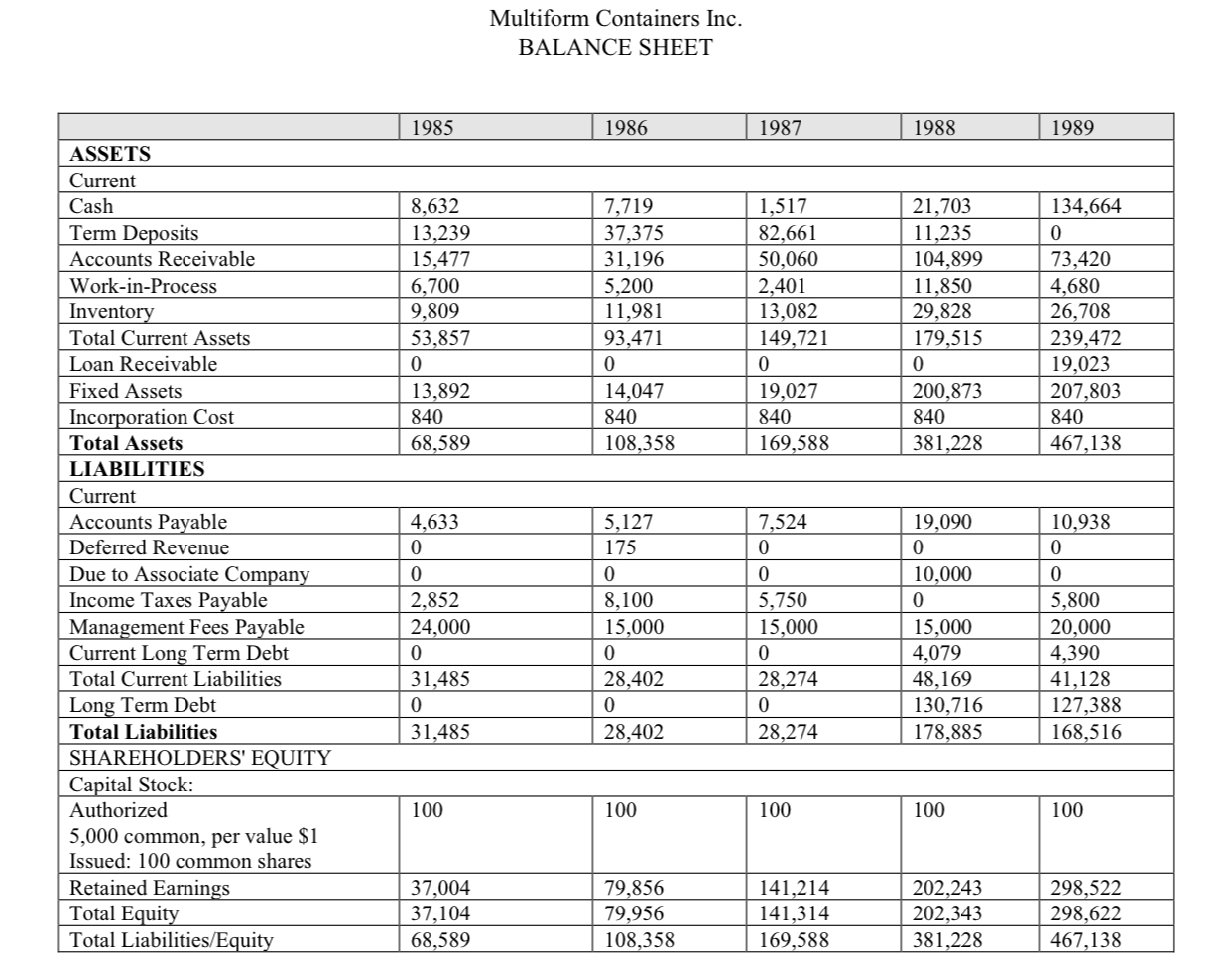

because the firm dealt with many small businesses, some of which "went bankrupt" because they did not have the capital or strength to carry through from the production stage to market.) Often a small manufacturer does not really know what he needs. For example, a company wanted to package candy. The owner spent $1200 for a package that he considered attractive and unique. The problem he ran into when he approached MCI box maker was that the package had too much colour variety and the design was awkward. The package would have cost $2.00 each to produce, while the selling price of the product allowed for a 50 cents package cost. So, MCI had to redesign the package. Small folding boxes constituted 40% of the business. Another large segment of MCI's business (40%) was to take material from the printing company and convert it to finished goods for the printing company. This included displays and promotion folders, which are completed by die-cutting. The remaining 20% of MCI's business involved taking large sheets of paperboard and cutting them into various dimensions for shirt boards, picture backs, and other products. Production Previously, Tom Foster and Harold Veinot went to the customer's plant. Now, they encouraged the customer to visit MCI's plant. This made it possible to show MCI's facilities and capabilities, and the customer felt he/she was part of the design process. Steps involved in producing the nished product were as follows: a) Customers knew their own products and where they were to be sold, but did not know how to make suitable boxes for the products. After listening to the customer's request, the box maker decided on the weight of paperboard required and made up a prototype box. b) Once the plant received the order, the die-maker took a piece of special plywood and made a die the that would be used to cut out the box shapes. The die was inserted into a steel frame in the die-cutting press. Sheets of paperboard were inserted in a frame that was aligned with the die. c) The drums of the press were rotated so that a continuous feed of paperboard sheets was pressed lightly against the die, and the steel rule in the die scored the paperboard. Later, the excess paper was stripped away manually, and the at form of the boxes were ready for shipment to the customer. Certain boxes required gluing, which was done by MCI. (The die-cutting process is illustrated in Exhibit 1) Equipment A polar cutter was used to cut the paperboard into sheets for die-cutting. A gluing machine was used to glue portions of boxes and folders when required. Three Heidleberg die-cutting presses of varying sizes were used to die-cut the boxes. The large press could handle most jobs, with the smaller presses being required for jobs with a very small dimension. Unlike printing presses, speed of output was not a consideration. If the press ran too fast, the die-cut pieces would fly into the air. On die-cut presses, the operator controls the speed. Multiform Containers Inc. INCOME STATEMENT 1985-1989 1985 1986 1987 1988 Revenue 1989 117,956 180,914 Materials & Supplies 271,320 297,645 29,995 441,350 Gross Margin 39,577 72,246 87,961 82,570 106,507 141,337 199,274 Expenses: 215,075 334.843 Accounting & Legal 1,054 1,120 Auto 1,688 2,451 888 6,494 8,024 Bad Debt 91134 8.549 803 11,962 897 Depreciation 1,353 870 2,996 6,235 3,091 Freight 4.439 20 7,748 0 15,888 4.619 Insurance 7,210 357 357 5,783 0 Interest & Bank Charges 0 325 1,895 148 LOW/Gain Sale of Assets 204 0 1,436 0 14,002 0 Management Fees 2,923 24,000 30,000 (3,734) Miscellaneous 45,000 45,000 0 555 0 Office Supplies 569 1,723 0 968 485 Rental Expense 1,651 676 2,308 2,078 3,266 Repairs & Maintenance 6,051 3,499 7,760 0 0 Relocation Expense 0 0 0 2,264 0 0 Taxes-Business 0 0 575 1,530 Utilities 1,616 2,018 2,247 5,643 3,082 Wages 3,261 8,561 23,088 35,192 12,123 Total Expenses 42,739 43,026 71,323 145,649 Net Income Before Taxes 87,192 122,324 139,951 16,638 54.145 218,642 Income Tax 76,950 75,124 116,201 2,852 Net Income After Taxes 11,293 15,592 13,786 14,095 42,852 19,922 61,358 Retained Earnings, Beginning 61,029 23,218 96,279 Retained Earnings, Ending 37,004 79,856 37,004 141,214 79,856 202,243 141,214 202,243 298,522Scenario Refer to the attached case study in Annex 1: Multiform Containers Inc. You are the Business Development Manager at Multiform Containers Inc and you report directly to Tom Foster/President. The Business Development department at the company is responsible for developing ideas, initiatives and activities aimed towards making the business better by increasing revenues, growth and business expansion, increasing protability, and building strategic partnerships. You have a team of 9 employees; two seniors and seven juniors. Tom Fosters's thoughts were to focus on a strategy that would provide direction for company growth and increased protability expansion. After careful examination of several choices, Foster and the top management (including you) decided expand into the printing business. This strategy came in-line with MCI's goal to \"to significantly increase the company's customers and sales". W 1. Explain the different types of plans used in business organizations 2. In order to implement the new strategy of MCI (to expand to the printing business), Foster asked you to develop an operational plan that would set clear objectives, activities, responsibilities, time frame, budget, and key performance indicators. The execution of the plan should be completed in one year (1990 1991). The total budget allocated for the plan would be 30% of the total expenses of the company for the year 1989. You need to define four sub-goals (objectives) using the SMART goal approach. Note: follow the plan template annexed to this assignment. 3. Explain the controlling process used in business organizations. 4. Financial controls are among the tools used in the controlling process. Use the financial statements in Exhibit 2 to calculate the Net Margin (profitability) and the Liquidity for each of the years 1935 1989. Multiform Containers Inc. BALANCE SHEET 1985 1986 1987 1988 ASSETS 1989 Current Cash 8.632 7,719 1,517 21,703 134,664 Term Deposits 13,239 37,375 82.661 11,235 0 Accounts Receivable 15,477 31,196 50,060 104,899 73,420 Work-in-Process 6,700 5,200 2,401 11,850 4,680 Inventory 9,809 11,981 13,082 29,828 26,708 Total Current Assets 53,857 93.471 149,721 Loan Receivable 179,515 239,472 0 0 0 0 19,023 Fixed Assets 13,892 14,047 19,027 200,873 Incorporation Cost 207,803 840 840 840 840 840 Total Assets 68,589 108,358 169,588 381,228 LIABILITIES 467,138 Current Accounts Payable 4,633 5,127 7,524 Deferred Revenue 19,090 10,938 0 175 0 0 0 Due to Associate Company 0 0 0 10,000 0 Income Taxes Payable 2,852 8,100 5,750 0 Management Fees Payable 5,800 24,000 15,000 15,000 15,000 Current Long Term Debt 20,000 0 0 0 4.079 4,390 Total Current Liabilities 31,485 28,402 28,274 Long Term Debt 48,169 41,128 0 0 0 130,716 Total Liabilities 127,388 31,485 28,402 28,274 SHAREHOLDERS' EQUITY 178,885 168,516 Capital Stock: Authorized 100 100 100 100 5,000 common, per value $1 100 Issued: 100 common shares Retained Earnings 37,004 79,856 141,214 202,243 Total Equity 298,522 37,104 79,956 141,314 Total Liabilities/Equity 202,343 298,622 68,589 108,358 169,588 381,228 467,138Tom Foster, James Aldrich, and Hamid Veinot worked in a branch plant where the production was transferred back to Toronto. Being salespeople for a plant located a thousand miles away was not satisfying, and they saw that the needs of smallr customers were not being met. By the late 19708, Tom Foster, James Aldrich, and Harold Veinot were actively considering starting their own business. They reasoned that low volumes would not interest large rms based in Montreal and Toronto. The group felt their skills and resources would be sufficient to compete with the small number of local rms. So, in 1980, Muitiform Containers Inc (MCI) was incorporated to produce folding boxes, counter displays, and other items requiring die-cutting (see Exhibit 1). Provincial governments were encouraging small businesses by building incubator malls. Each mall would accommodate three to four businesses in separate spaces of 2,000-4,000 square feet. The rent for these spaces was subsidized for the rst three years, giving new industries a chance to get started. MCI took advantage of this arrangement. In time, they outgrew this space. In 1987, they built their own plant. Products The company produced products which were made from sheets of paperboard of varying thickness, depending on the strength required in the boxes. Through effective purchasing, MCI's paperboard costs made an important contribution to protability. Box design was the responsibility of the box manufacturer in consultation with the customer. Designs varied, depending on the product and whether or not the customer wanted a box that was different from existing boxes. It was important to design a box that was easy to make and economic to use (ie., space economy in packing boxes into larger cartons for shipping). Boxes were made in numerous shapes: cube, rectangular, round, and oval. Even though the print and the colour of a box was decided by the printer, the box manufacturer's input was necessary, as he was often the individual having the rst contact with the customer. Two packaging experts, discussing importance of colour in packaging, stated: "A housewife in front of me reached for our product on the shelf in a shop. I asked her why she had chosen this brand. Her response, 'I really wanted to buy (and named a competing product),' but she could not nd it. The package was, in fact, next to ours. But, since our package had been designed to attract and retain attention, she did not bother to look at others": The package is the face of the product. The customer recognized his' toothpaste, 'his' chocolate, by the colour, shape, and design of its package. An advertising campaign loses its value if the product is not easily recognized in the shop. The package must, moreover, not only lead to a single purchase but encourage repeat purchases by the customer (repeat business). Marketing MCI concentrated on developing the market niche serving businesses with low volumes, businesses which were of less interest to large, printing, die-cutting companies. MCI's emphasized products that needed special packaging. The quantities were not large, and a quick tum-around was important. MCI was not interested in trying to take business from large competitors. Such a strategy would lower margins and require extra investment in equipment. Those would be risks taken for business which the competitor could take back at any time. The approach Tom Foster preferred was to create new business by design in g boxes for small companies who did not have the skills themselves. To date, this provided about 150 customers requiring regular contact. Experience showed that such an approach resulted in repeat business of about 30%. (About 70% of the business was not repeat Multiform Containers Inc. 1 In the summer of 1989, Tom Foster, President of Multiform Containers Inc. (MCI), received the nancial statements for the year ended February 28 from his accountant. The numbers conrmed that a visible market niche existed for a small company specializing in producing paperboard boxes for local manufacturers. Two years earlier, the company had expanded to a new building in Sackville, Nova Scotia. Foster was pleased with the results but was wondering how to maintain his past success. As he said, "The year's results were pretty good. But if someone asked what strategy we used I would have to say 'none,' at least nothing on paper. I had a certain philosophy about running the company. I didn't hire extra staff or invest in equipment unless it was absolutely necessary; before purchasing raw materials I shopped around looking for ends of line that would do the job, so, I could be satised that my raw material costs were as low as possible, and I watched expenses very closely, so some might say I was 'nickel and diming' it. Comments like this didn't bother me because, in the end, I knew that what I had done would improve my prots." Where do we go from here? To replace the existing machinery with new, more efcient equipment would cost about three quarters of a million dollars. Foster was not certain in his own mind that this was "absolutely necessary," nor did he like the long-tenn debt that would go along with equipment replacement. In thinking of areas for growth and expansion, several possibilities came to mind: (I) Aggressively seek out new customers and increase sales to current customers. (2) Expand into the printing business. (3) Construct a separate building on a vacant piece of land and rent it to a small printing company. He thought it would be good for his business to have such companies located nearby. Foster had to decide which choices to make to hirther the interests of the company. The Company Historically, boxes made from paperboard/cardboard were supplied to Atlantic Canadian users by large printing companies located in Montreal or Toronto. The predecessor to a folding box was a set-up box (one example of a set- up box was a chocolate box made in two pieces and shipped to the customer assembled). Such boxes had the problem of requiring extra storage and shipping costs. So, it was convenient for larger companies in central Canada to locate branch plants in Atlantic Canada to produce boxes for shing companies, confectionery companies, and others with similar packaging needs. 0n ce folding boxes were developed that could be manufactured, stored, and shipped at, the need for branch plants diminished. Plans were in the works to buy one or two new presses, because some printers who normally did not have die-making skills set markings that were not accurate enough. The box maker had to take the job off of the press, make a new die, run a proof, and send it back to the printer for approval. So the machine could be tied up for two or three days, or the job could be removed and a second set-up done later. That is why it is useful to have extra presses for exibility, which enables good planning. MCI bought used equipment to cut cost. A gluing machine could cost as much as $400,000 and a secondhand machine as low as $5,000. One used machine was purchased for $5,000, but the machine could not be adapted, so it was written off. The next purchase was perfect: for a total outlay of $10,000, the company's needs were satised. MCI had no problem with conversion or maintenance costs, and by purchasing used equipment, large bank loans for equipment were not necessary. Financial Assistance in nancing the equipment purchased and construction of a building was provided by ACOA and its predecessor. Total assistance was approximately $88,000 on a total cost of $335,000. Additional assistance in the purchase of equipment was provided by the Province's Department of Small Business Development. This nancial assistance help was obtained through programs meant to encourage small businesses to start, grow, and expand. In the case of MCI, the programs did exactly that. A ve-year income statement reected 1989 sales of $441,350, an increase of $143,705 over the previous year and an increase of $323,394 since 1985. Earnings after taxes, at $96,279, were the highest in ve years. Tom Foster gave the nancial statements to his part-time receptionist/oice clerk for ling. His thoughts continued to focus on a strategy that would provide direction for company grow}: and increased protability