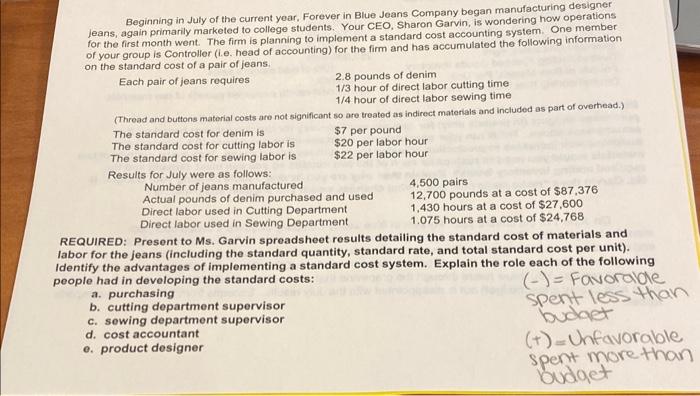

Beginning in July of the current year. Forever in Blue Jeans Company began manufacturing designer leans, again primarily marketed to college students. Your CEO, Sharon Garvin, is wondering how operations for the first month went. The firm is planning to implement a standard cost accounting system. One member of your group is Controller (i.e. head of accounting) for the firm and has accumulated the following information on the standard cost of a pair of jeans. Each pair of jeans roquires 2.8 pounds of denim 1/3 hour of direct labor cutting time 1/4 hour of direct labor sewing time (Thread and buttons material costs are not significant so are treated as indirect materials and included as part of overtiead.) The standard cost for denim is $7 per pound The standard cost for cutting labor is \$20 per labor hour The standard cost for sewing labor is $22 per labor hour Results for July were as follows: NumberofjeansmanufacturedActualpoundsofdenimpurchasedandusedDirectlaborusedinCuttingDepartmentDirectlaborusedinSewingDepartment4,500pairs12,700poundsatacostof$87,3761,430hoursatacostof$27,6001.075hoursatacostof$24,768 REQUIRED: Present to Ms. Garvin spreadsheet results detailing the standard cost of materials and labor for the jeans (including the standard quantity, standard rate, and total standard cost per unit). Identify the advantages of implementing a standard cost system. Explain the role each of the following people had in developing the standard costs: a. purchasing b. cutting dopartment supervisor c. sowing department supervisor d. cost accountant e. product designer Beginning in July of the current year. Forever in Blue Jeans Company began manufacturing designer leans, again primarily marketed to college students. Your CEO, Sharon Garvin, is wondering how operations for the first month went. The firm is planning to implement a standard cost accounting system. One member of your group is Controller (i.e. head of accounting) for the firm and has accumulated the following information on the standard cost of a pair of jeans. Each pair of jeans roquires 2.8 pounds of denim 1/3 hour of direct labor cutting time 1/4 hour of direct labor sewing time (Thread and buttons material costs are not significant so are treated as indirect materials and included as part of overtiead.) The standard cost for denim is $7 per pound The standard cost for cutting labor is \$20 per labor hour The standard cost for sewing labor is $22 per labor hour Results for July were as follows: NumberofjeansmanufacturedActualpoundsofdenimpurchasedandusedDirectlaborusedinCuttingDepartmentDirectlaborusedinSewingDepartment4,500pairs12,700poundsatacostof$87,3761,430hoursatacostof$27,6001.075hoursatacostof$24,768 REQUIRED: Present to Ms. Garvin spreadsheet results detailing the standard cost of materials and labor for the jeans (including the standard quantity, standard rate, and total standard cost per unit). Identify the advantages of implementing a standard cost system. Explain the role each of the following people had in developing the standard costs: a. purchasing b. cutting dopartment supervisor c. sowing department supervisor d. cost accountant e. product designer