Answered step by step

Verified Expert Solution

Question

1 Approved Answer

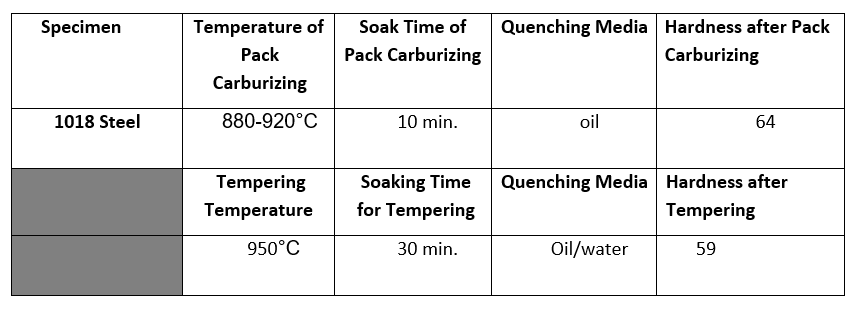

begin{tabular}{|c|c|c|c|l|} hline Specimen & TemperatureofPackCarburizing & SoakTimeofPackCarburizing & Quenching Media & HardnessafterPackCarburizing hline 1018Steel & 880920C & 10 min. & oil & 64

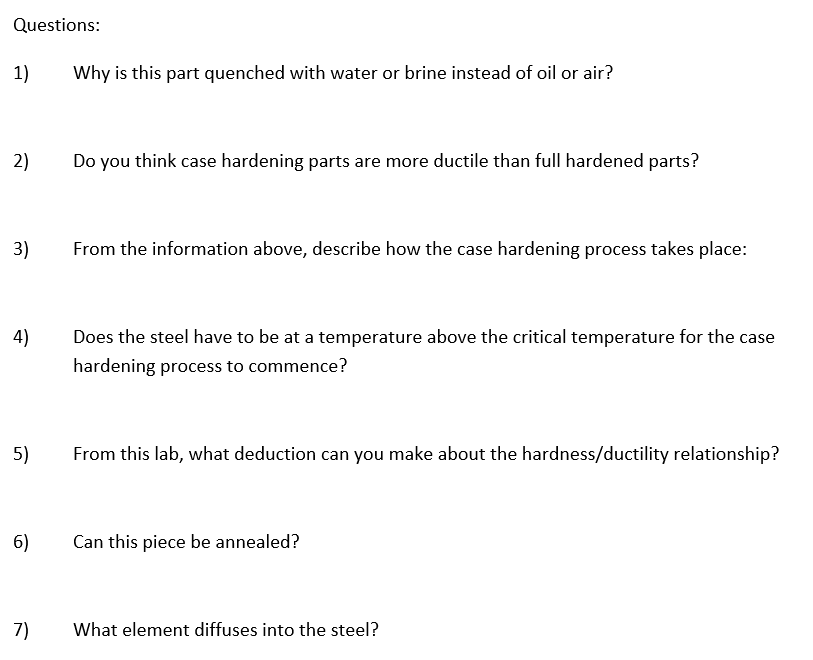

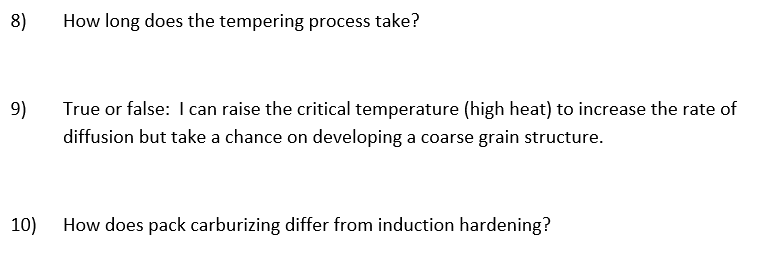

\begin{tabular}{|c|c|c|c|l|} \hline Specimen & TemperatureofPackCarburizing & SoakTimeofPackCarburizing & Quenching Media & HardnessafterPackCarburizing \\ \hline 1018Steel & 880920C & 10 min. & oil & 64 \\ \hline & TemperingTemperature & SoakingTimeforTempering & Quenching Media & HardnessafterTempering \\ \hline & 950C & 30min. & Oil/water & 59 \\ \hline \end{tabular} 1) Why is this part quenched with water or brine instead of oil or air? 2) Do you think case hardening parts are more ductile than full hardened parts? 3) From the information above, describe how the case hardening process takes place: 4) Does the steel have to be at a temperature above the critical temperature for the case hardening process to commence? 5) From this lab, what deduction can you make about the hardness/ductility relationship? 6) Can this piece be annealed? 7) What element diffuses into the steel? 8) How long does the tempering process take? 9) True or false: I can raise the critical temperature (high heat) to increase the rate of diffusion but take a chance on developing a coarse grain structure. 10) How does pack carburizing differ from induction hardening

\begin{tabular}{|c|c|c|c|l|} \hline Specimen & TemperatureofPackCarburizing & SoakTimeofPackCarburizing & Quenching Media & HardnessafterPackCarburizing \\ \hline 1018Steel & 880920C & 10 min. & oil & 64 \\ \hline & TemperingTemperature & SoakingTimeforTempering & Quenching Media & HardnessafterTempering \\ \hline & 950C & 30min. & Oil/water & 59 \\ \hline \end{tabular} 1) Why is this part quenched with water or brine instead of oil or air? 2) Do you think case hardening parts are more ductile than full hardened parts? 3) From the information above, describe how the case hardening process takes place: 4) Does the steel have to be at a temperature above the critical temperature for the case hardening process to commence? 5) From this lab, what deduction can you make about the hardness/ductility relationship? 6) Can this piece be annealed? 7) What element diffuses into the steel? 8) How long does the tempering process take? 9) True or false: I can raise the critical temperature (high heat) to increase the rate of diffusion but take a chance on developing a coarse grain structure. 10) How does pack carburizing differ from induction hardening Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started