Question

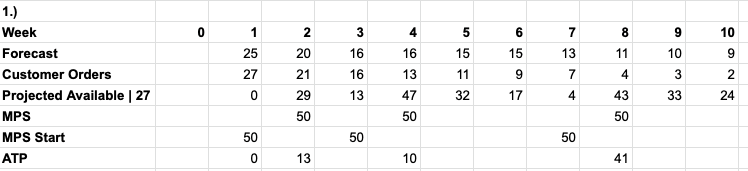

Benzie Products Company produces several lines of products, but one (they call it product X) uses unique parts to produce it and the demand is

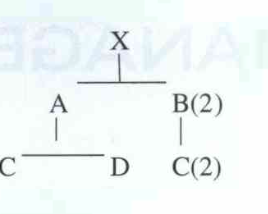

Benzie Products Company produces several lines of products, but one (they call it product X) uses unique parts to produce it and the demand is very seasonal. There are some possible variations in the design, so the company tends to use available-to-promise (ATP) logic to master schedule the product. Since the components to produce it are quite expensive, the company tries very hard to minimize any inventory of the product or its com ponents during the seasons with very low sales. Product X is just now entering the low season, and the following chart represents the forecast data and actual customer orders for the next ten weeks: There are currently (at the start of week 1) 27 product X left in inventory. The follow ing represents the product structure for product X:

Relevant data for components A, B, C, and D at the start of week 1.

| Component | A | B | C | D |

| Starting Inventory | 0 | 112 | 212 | 98 |

| Lead time (weeks) | 2 | 1 | 1 | 3 |

| Lot Size | FOQ=60 | POQ w/P=4 weeks | LFL | FOQ=100 |

| Safety Stock | 0 | 10 | 20 | 0 |

| Scrap Factor |

|

| 10% |

|

In addition, item D has independent demand of 5 units/week. Also, item A has a scheduled receipt of 60 units for week 1.

From the master schedule for Product X and using the data given for components. C and D, create MRP grids for each for the components for the next ten weeks.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started