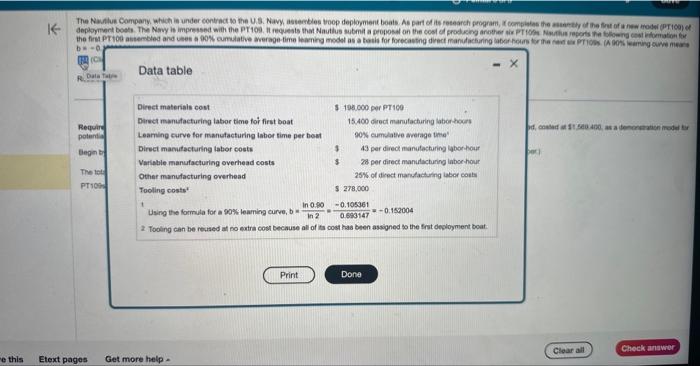

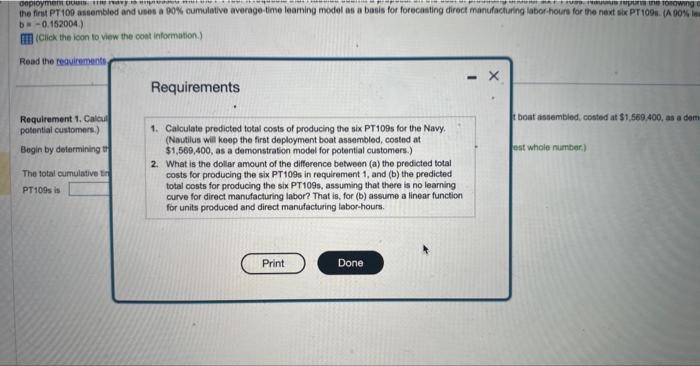

B=i=0.152004] (Cich the icon so virw the coel infornation.) Fend the treatements potertial cuastomer. hours, therefore, the lotal sene to srotvice air priope is hars. 2. Tooling can be reised at no extra cost because all of ita cost has been assigned so the frat deployment boat: Clear all Gheck anaver Etext pages Get more help - the firut PT 100 assembled and ubes a 00% cumulative average-time learning model as a basis for forecasting direct manufachuring labor hours for the next six PT 109k. (A 90%. b=0.152004. (cickck the icon to view the coet information.) Read the teavimements Requirements Requirement 1. Calcul potentiai customers.) 1. Calculate predicted total costs of producing the six PT109s for the Navy. (Nautilus wili keep the first deployment boat assembled, costed at $1,569,400, as a demonstration model for potential customers.) 2. What is the dollar amount of the difference between (a) the predicted total costs for producing the six PT 109s in requirement 1, and (b) the predicted total costs for producing the six PT109s, assuming that there is no learning curve for direct manufacturing labor? That is, for (b) assume a linear function for units produced and direct manufacturing labor:hours. The Nautius Company, which is under contract to the U.S. Navy. assembles troop deployment boats. As part of lss research program, it oampletes the astembly of the firat of a new modet (PT 10g) ef deployment boath. The Nony is impressed with the PTtC9. It reguests that Naublus submit a proposal on the cost of producing another six PT ICOs. Nasuthis foports the folowing coat inlomation bor b=0.152004.1 (Click the ioen to view the cost itormation) Fiead the potectad customers) Begin by determaning the hours used to produce the six PT109s for the Nayy. TRound inormedary and final anaweci io the nosmeat anole number) The iotal curmalaive time in labor hours for seven PT 109 is hours: therefore, the lotal time to produce ex PTtoos is B=i=0.152004] (Cich the icon so virw the coel infornation.) Fend the treatements potertial cuastomer. hours, therefore, the lotal sene to srotvice air priope is hars. 2. Tooling can be reised at no extra cost because all of ita cost has been assigned so the frat deployment boat: Clear all Gheck anaver Etext pages Get more help - the firut PT 100 assembled and ubes a 00% cumulative average-time learning model as a basis for forecasting direct manufachuring labor hours for the next six PT 109k. (A 90%. b=0.152004. (cickck the icon to view the coet information.) Read the teavimements Requirements Requirement 1. Calcul potentiai customers.) 1. Calculate predicted total costs of producing the six PT109s for the Navy. (Nautilus wili keep the first deployment boat assembled, costed at $1,569,400, as a demonstration model for potential customers.) 2. What is the dollar amount of the difference between (a) the predicted total costs for producing the six PT 109s in requirement 1, and (b) the predicted total costs for producing the six PT109s, assuming that there is no learning curve for direct manufacturing labor? That is, for (b) assume a linear function for units produced and direct manufacturing labor:hours. The Nautius Company, which is under contract to the U.S. Navy. assembles troop deployment boats. As part of lss research program, it oampletes the astembly of the firat of a new modet (PT 10g) ef deployment boath. The Nony is impressed with the PTtC9. It reguests that Naublus submit a proposal on the cost of producing another six PT ICOs. Nasuthis foports the folowing coat inlomation bor b=0.152004.1 (Click the ioen to view the cost itormation) Fiead the potectad customers) Begin by determaning the hours used to produce the six PT109s for the Nayy. TRound inormedary and final anaweci io the nosmeat anole number) The iotal curmalaive time in labor hours for seven PT 109 is hours: therefore, the lotal time to produce ex PTtoos is