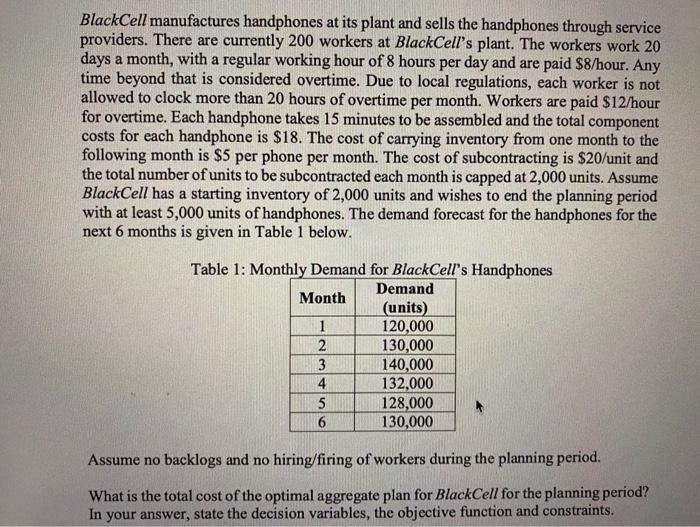

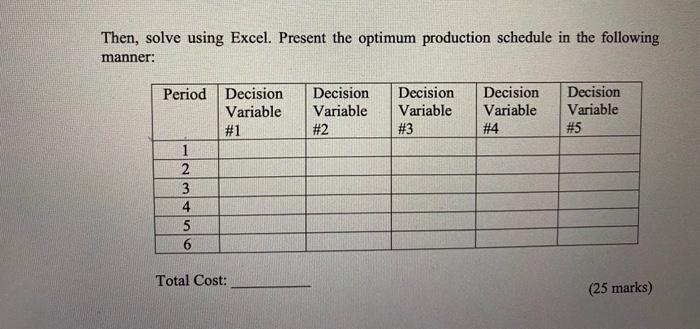

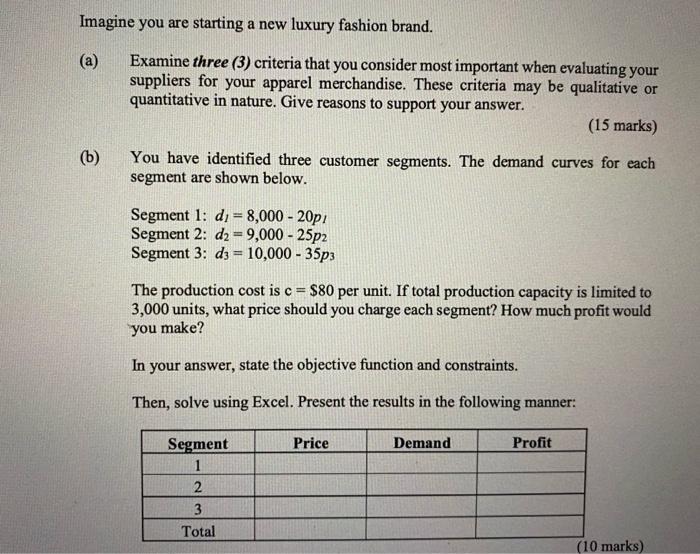

BlackCell manufactures handphones at its plant and sells the handphones through service providers. There are currently 200 workers at BlackCell's plant. The workers work 20 days a month, with a regular working hour of 8 hours per day and are paid $8/hour. Any time beyond that is considered overtime. Due to local regulations, each worker is not allowed to clock more than 20 hours of overtime per month. Workers are paid $12/hour for overtime. Each handphone takes 15 minutes to be assembled and the total component costs for each handphone is $18. The cost of carrying inventory from one month to the following month is $5 per phone per month. The cost of subcontracting is $20/unit and the total number of units to be subcontracted each month is capped at 2,000 units. Assume BlackCell has a starting inventory of 2,000 units and wishes to end the planning period with at least 5,000 units of handphones. The demand forecast for the handphones for the next 6 onths is given in Table 1 below. Table 1: Monthly Demand for BlackCell's Handphones Demand Month (units) 1 120,000 2 130,000 3 140,000 4 132,000 5 128,000 6 130,000 Assume no backlogs and no hiring/firing of workers during the planning period. What is the total cost of the optimal aggregate plan for BlackCell for the planning period? In your answer, state the decision variables, the objective function and constraints. Then, solve using Excel. Present the optimum production schedule in the following manner: Decision Variable #2 Decision Variable #3 Decision Variable #4 Decision Variable #5 Period Decision Variable #1 1 2 3 4 5 6 Total Cost: (25 marks) Imagine you are starting a new luxury fashion brand. (a) Examine three (3) criteria that you consider most important when evaluating your suppliers for your apparel merchandise. These criteria may be qualitative or quantitative in nature. Give reasons to support your answer. (15 marks) (6) You have identified three customer segments. The demand curves for each segment are shown below. Segment 1: di = 8,000 - 20p, Segment 2: d2 = 9,000 - 25p2 Segment 3: d3 = 10,000 - 35p3 The production cost is c = $80 per unit. If total production capacity is limited to 3,000 units, what price should you charge each segment? How much profit would you make? In your answer, state the objective function and constraints. Then, solve using Excel. Present the results in the following manner: Price Demand Profit Segment 1 2 3 Total (10 marks)