Bradford mini case

PLEASE answer this question: Please determine the production plan/schedule (by indicating the number of lines and overtime hrs per day), and the budget (costs) associated with the plan - these are the blue ighlighted sections of the worksheet - Please determine how many production lines to run, how many hours of overtime to work per day, and the corresponding budget line items in the lower highlighted budget section - you can use the defaulted number of production lines and overtime hours as a first try. Thanks!!

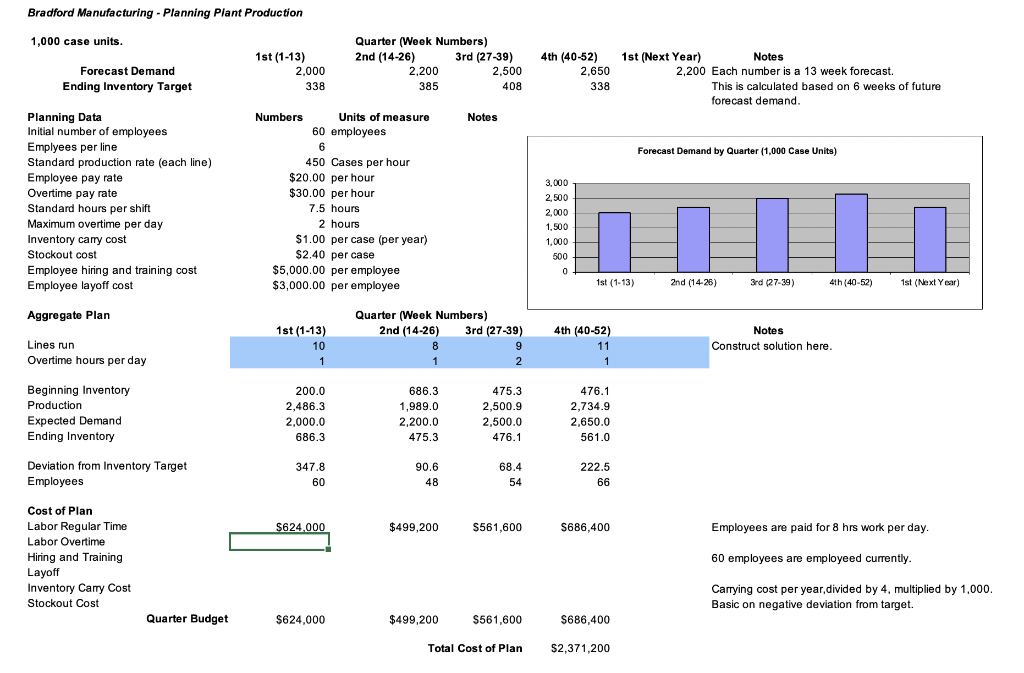

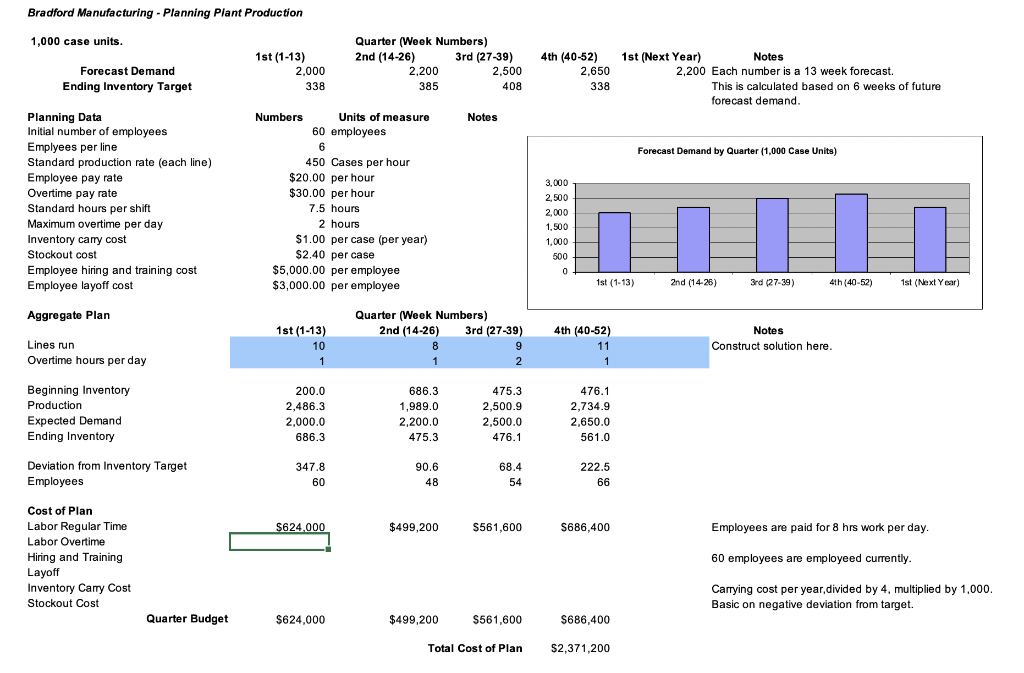

Bradford Manufacturing - Planning Plant Production 1,000 case units. Quarter (Week Numbers) 2nd (14-26) 3rd (27-39) 2,200 2,500 385 408 1st (1-13) 2.000 338 Forecast Demand Ending Inventory Target 4th (40-52) 2,650 338 1st (Next Year) Notes 2,200 Each number is a 13 week forecast. This is calculated based on 6 weeks of future forecast demand. . Notes Forecast Demand by Quarter (1,000 Case Units) Planning Data Initial number of employees Emplyees per line Standard production rate (each line) Employee pay rate Overtime pay rate Standard hours per shift Maximum overtime per day Inventory carry cost Stockout cost Employee hiring and training cost Employee layoff cost Numbers Units of measure 60 employees 6 6 450 Cases per hour $20.00 per hour $30.00 per hour 7.5 hours 2 hours 3,000 2.500 2,000 1,500 1,000 500 $1.00 per case (per year) $2.40 per case $5,000.00 per employee $3,000.00 per employee $ 0 1st (1-13) 2nd (14-26) 3rd (27-39) 4th (40-52) 1st (Next Year) Aggregate Plan 1st (1-13) Quarter (Week Numbers) 2nd (14-26) 3rd (27-39) 8 8 9 2 Lines run Overtime hours per day 4th (40-52) 11 1 Notes Construct solution here. 10 1 Beginning Inventory Production Expected Demand Ending Inventory 200.0 2,486.3 2,000.0 686.3 686.3 1,989.0 2,200.0 475.3 475.3 2,500.9 2,500.0 476.1 476.1 2,734.9 2,650.0 561.0 Deviation from Inventory Target Employees 347.8 60 90.6 48 68.4 54 222.5 66 $624.000 $499,200 $561,600 S686,400 Employees are paid for 8 hrs work per day. Cost of Plan Labor Regular Time Labor Overtime Hiring and Training Layoff Inventory Carry Cost Stockout Cost 60 employees are employeed currently. Carrying cost per year, divided by 4, multiplied by 1,000. Basic on negative deviation from target. Quarter Budget $624,000 $499,200 $561,600 $ $686,400 Total Cost of Plan $2,371,200 Bradford Manufacturing - Planning Plant Production 1,000 case units. Quarter (Week Numbers) 2nd (14-26) 3rd (27-39) 2,200 2,500 385 408 1st (1-13) 2.000 338 Forecast Demand Ending Inventory Target 4th (40-52) 2,650 338 1st (Next Year) Notes 2,200 Each number is a 13 week forecast. This is calculated based on 6 weeks of future forecast demand. . Notes Forecast Demand by Quarter (1,000 Case Units) Planning Data Initial number of employees Emplyees per line Standard production rate (each line) Employee pay rate Overtime pay rate Standard hours per shift Maximum overtime per day Inventory carry cost Stockout cost Employee hiring and training cost Employee layoff cost Numbers Units of measure 60 employees 6 6 450 Cases per hour $20.00 per hour $30.00 per hour 7.5 hours 2 hours 3,000 2.500 2,000 1,500 1,000 500 $1.00 per case (per year) $2.40 per case $5,000.00 per employee $3,000.00 per employee $ 0 1st (1-13) 2nd (14-26) 3rd (27-39) 4th (40-52) 1st (Next Year) Aggregate Plan 1st (1-13) Quarter (Week Numbers) 2nd (14-26) 3rd (27-39) 8 8 9 2 Lines run Overtime hours per day 4th (40-52) 11 1 Notes Construct solution here. 10 1 Beginning Inventory Production Expected Demand Ending Inventory 200.0 2,486.3 2,000.0 686.3 686.3 1,989.0 2,200.0 475.3 475.3 2,500.9 2,500.0 476.1 476.1 2,734.9 2,650.0 561.0 Deviation from Inventory Target Employees 347.8 60 90.6 48 68.4 54 222.5 66 $624.000 $499,200 $561,600 S686,400 Employees are paid for 8 hrs work per day. Cost of Plan Labor Regular Time Labor Overtime Hiring and Training Layoff Inventory Carry Cost Stockout Cost 60 employees are employeed currently. Carrying cost per year, divided by 4, multiplied by 1,000. Basic on negative deviation from target. Quarter Budget $624,000 $499,200 $561,600 $ $686,400 Total Cost of Plan $2,371,200