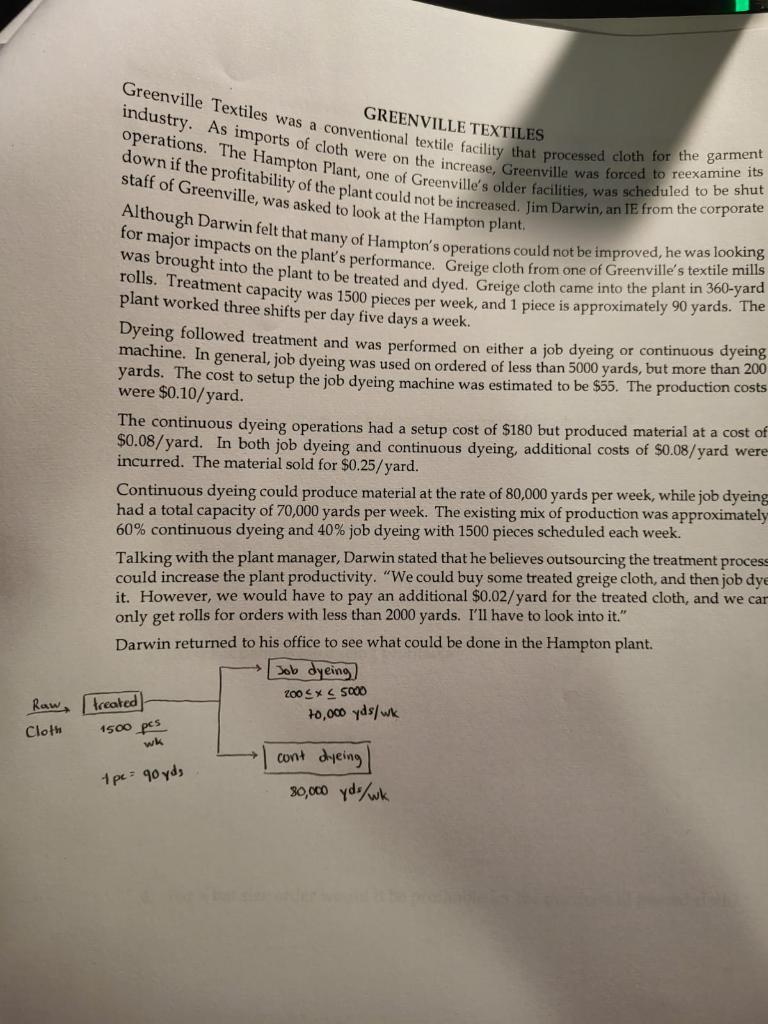

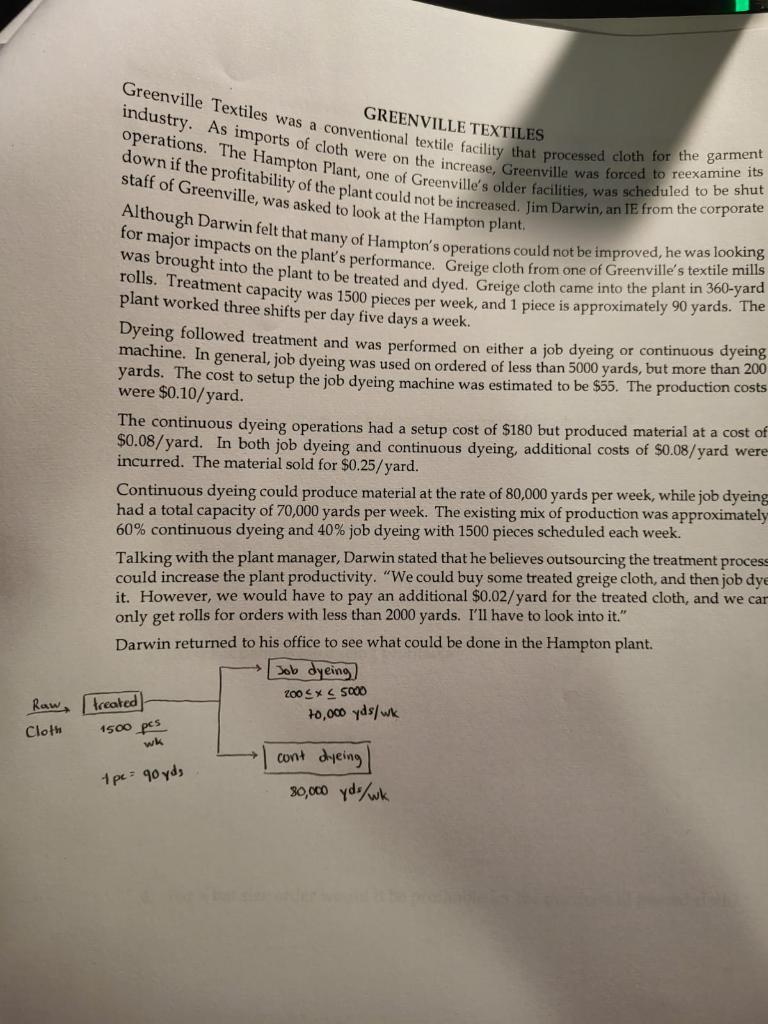

Break Even Points Greenville Textiles - Please answer the following questions. 1. At what level of production (how many units produced) does job dyeing and continuous dyeing have the same return (hint: this is the break-even point between the two processes) "same return" is asking for when profits are equal - 2. When should we use continuous dyeing instead of job dyeing? 3. At what point is job dyeing profitable? 4. For what size order would it be profitable for the purchase of treated cloth? Greenville Textiles was a conventional textile Tacilites industry. As imports of conventional textile facility that processed cloth for the garment operations. The Hampton Ploth were on the increase, Greenville was forced to reexamine its down if the profitability of Plant, one of Greenville's older facilities, was scheduled to be shut staff of Greenville, was of the plant could not be increased. Jim Darwin, an IE from the corporate for major impacts felt that many of Hampton's operations could not be improved, he was looking was brought impacts on the plant's performance. Greige cloth from one of Greenville's textile mills to the plant to be treated and dyed. Greige cloth came into the plant in 360-yard rolls. Treatment capacity was 1500 pieces per week, and 1 piece is approximately 90 yards. The plant worked three shifts per day five days a week. Dyeing followed treatment and was performed on either a job dyeing or continuous dyeing machine. In general, job dyeing was used on ordered of less than 5000 yards, but more than 200 yards. The cost to setup the job dyeing machine was estimated to be $55. The production costs were $0.10 / yard. The continuous dyeing operations had a setup cost of $180 but produced material at a cost of $0.08/ yard. In both job dyeing and continuous dyeing, additional costs of $0.08/ yard were incurred. The material sold for $0.25/ yard. Continuous dyeing could produce material at the rate of 80,000 yards per week, while job dyeing had a total capacity of 70,000 yards per week. The existing mix of production was approximately 60% continuous dyeing and 40% job dyeing with 1500 pieces scheduled each week. Talking with the plant manager, Darwin stated that he believes outsourcing the treatment process could increase the plant productivity. "We could buy some treated greige cloth, and then job dye it. However, we would have to pay an additional $0.02 /yard for the treated cloth, and we car only get rolls for orders with less than 2000 yards. I'll have to look into it." Darwin returned to his office to see what could be done in the Hampton plant. Break Even Points Greenville Textiles - Please answer the following questions. 1. At what level of production (how many units produced) does job dyeing and continuous dyeing have the same return (hint: this is the break-even point between the two processes) "same return" is asking for when profits are equal - 2. When should we use continuous dyeing instead of job dyeing? 3. At what point is job dyeing profitable? 4. For what size order would it be profitable for the purchase of treated cloth? Greenville Textiles was a conventional textile Tacilites industry. As imports of conventional textile facility that processed cloth for the garment operations. The Hampton Ploth were on the increase, Greenville was forced to reexamine its down if the profitability of Plant, one of Greenville's older facilities, was scheduled to be shut staff of Greenville, was of the plant could not be increased. Jim Darwin, an IE from the corporate for major impacts felt that many of Hampton's operations could not be improved, he was looking was brought impacts on the plant's performance. Greige cloth from one of Greenville's textile mills to the plant to be treated and dyed. Greige cloth came into the plant in 360-yard rolls. Treatment capacity was 1500 pieces per week, and 1 piece is approximately 90 yards. The plant worked three shifts per day five days a week. Dyeing followed treatment and was performed on either a job dyeing or continuous dyeing machine. In general, job dyeing was used on ordered of less than 5000 yards, but more than 200 yards. The cost to setup the job dyeing machine was estimated to be $55. The production costs were $0.10 / yard. The continuous dyeing operations had a setup cost of $180 but produced material at a cost of $0.08/ yard. In both job dyeing and continuous dyeing, additional costs of $0.08/ yard were incurred. The material sold for $0.25/ yard. Continuous dyeing could produce material at the rate of 80,000 yards per week, while job dyeing had a total capacity of 70,000 yards per week. The existing mix of production was approximately 60% continuous dyeing and 40% job dyeing with 1500 pieces scheduled each week. Talking with the plant manager, Darwin stated that he believes outsourcing the treatment process could increase the plant productivity. "We could buy some treated greige cloth, and then job dye it. However, we would have to pay an additional $0.02 /yard for the treated cloth, and we car only get rolls for orders with less than 2000 yards. I'll have to look into it." Darwin returned to his office to see what could be done in the Hampton plant