Question

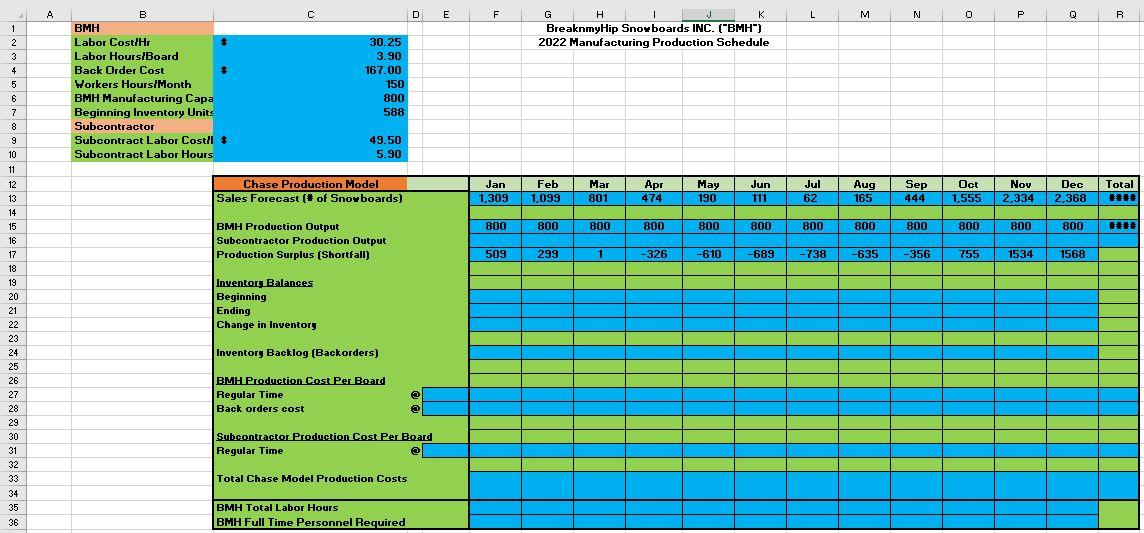

BreaknmyHip (BMH) Snowboards has completed its annual sales forecasting process and the sales forecast is included in the tab labeled 20XX Sales Forecast. Link that

BreaknmyHip ("BMH") Snowboards has completed its annual sales forecasting process and the sales forecast is included in the tab labeled 20XX Sales Forecast. Link that data to this sheet.

Students must now prepare a manufacturing production model that considers the capabilities of the BreaknmyHip manufacturing facility capabilities.

In this worksheet, students are asked to produce a production schedule using a pure "Chase" production modeling technique. This model should calculate total production costs, using the variables outlined herein, and also project the number of personnel required to complete the production plan. Students will need to create formulas to properly calculate all of the cells in the BLUE HIGHLIGHTED areas.

BreaknmyHip can produce a maximum of 800 snowboards per month, using regular labor time (no overtime), from its own manufacturing facility located in North Bend, OR. Labor costs per hour are an average of $30.25 and the average worker is present for 150 hours per month. Each snowboard takes a cumulative of 3.9 hours of labor cost to produce. BreaknmyHip wants to keep a level workforce in its facility yearlong. Beginning inventory coming into Jan is 588 units and BMH requres at least the same amount inventory at year end.

Sales and Finance have worked together and determined that each unit of backlog (i.e. an out of stock that results in a backorder) costs the company $167 in lost gross profit and impact to brand reputation. BreaknmyHip management historically has strived to keep all manufacturing "in-house" in order to better control quality of output.

However, the growth of the new sales forecast comes with growing customer concerns over back orders. BreaknmyHip must now considering subcontracting its production shortfall to another manufacturer with the goal to eliminate ALL backorders. The subcontractor's labor costs are $49.50 per hour and because of the lack of familiarity with the production process, each snowboard produced by the subcontractor will require 5.90 hours of labor cost to produce.

Students are now asked to prepare the production model using the variables outlined herein and through creating formulas in the BLUE HIGHLIGHTED sections of the spreadsheet.

Be sure to calculate all BLUE HIGHLIGHTED areas and be able to determine TOTAL PRODUCTION COST for each month and the year in total and the number of full time personnel required each month to produce the manufacturing production plan.

Once the data is completed per the above instructions, students should evaluate the model results and make notes for the class workshop discussion regarding areas of concern that the model may point out and ideas around how BreaknmyHip might address such concerns or opportunities.

For example, how are BMH "Artisan" Workers going to react to this model?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started