Question

Buckeye Manufacturing produces heads for engines used in the manufacture of trucks. The production line is highly complex, and it measures 900 feet in length.

Buckeye Manufacturing produces heads for engines used in the manufacture of trucks. The production line is highly complex, and it measures 900 feet in length. Two types of engine heads are produced on this line: the P-Head and the H-Head. The P-Head is used in heavy-duty trucks and the H-Head is used in smaller trucks. Because only one type of head can be produced at a time, the line is set up to manufacture either the P-Head or the H-Head, but not both. Changeovers are made over a weekend; costs are $500 in going from a setup for the P-Head to a setup for the H-Head, and vice versa. When set up for the P-Head, the maximum production rate is 100 units per week and when set up for the H-Head, the maximum production rate is 80 units per week.

Buckeye just shut down for the week after using the line to produce the P-Head. The manager wants to plan production and changeovers for the next eight weeks. Currently, Buckeye's inventory consists of 125 P-Heads and 143 H-Heads. Inventory carrying costs are charged at an annual rate of 19.5% of the value of inventory. The production cost for the P-Head if $225, and the production cost for the H-Head is $310. The objective in developing a production schedule is to minimize the sum of production cost, plus inventory carrying cost, plus changeover cost.

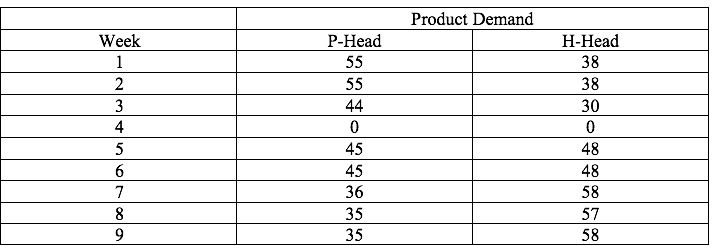

Buckeye received the following requirements schedule from its customer (an engine assembly plant) for the next nine weeks:

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started